OPERON D 850 SURGICAL TABLE

PRINCIPLES OF OPERATION

Rev. 1 700000120

3-5

6. The variable flow control valve on the

return line can control the flow or

cylinder speed.

• A flow control screw on each valve

can be adjusted with a 2.5mm Alan

wrench.

• Turning the screw clockwise reduces

the flow. (See the drawing above for

the location of the flow control

screws.)

7. When power is removed from the

solenoid, the valve locks in the neutral

position. This prevents any cylinder

movement.

COLUMN HYDRAULICS

General Information

The drawing below shows a schematic of the

column cylinders.

All cylinders in the column are dual actuated,

which means that hydraulic pressure is required

to push the cylinder in both directions. The foot

locks, which are on the base, are single action

poppet valves: pressure is required only to move

the legs to the locked position.

There are 3 lift cylinders: One in the lower stage

and the other in the upper stage.

The lift cylinders are not field replaceable.

Although highly unlikely, a failure of one of

these cylinders will require that the table be

returned to the manufacturing facility for repair.

A loaner table may be shipped for the customer

to use while repairs are being made.

There is one Trendelenburg cylinder.

There is one Tilt Cylinder.

There are two hydraulic fluid distribution blocks

to connect many of the valves and cylinders.

The solenoid valves on the “A” side in the

schematic are on the left side of the hydraulic

manifold, and the solenoid valves on “B” side in

the schematic are on the right side of the

manifold.

All solenoid valve labels start with “Y”

The column Solenoids and their functions are

listed below.

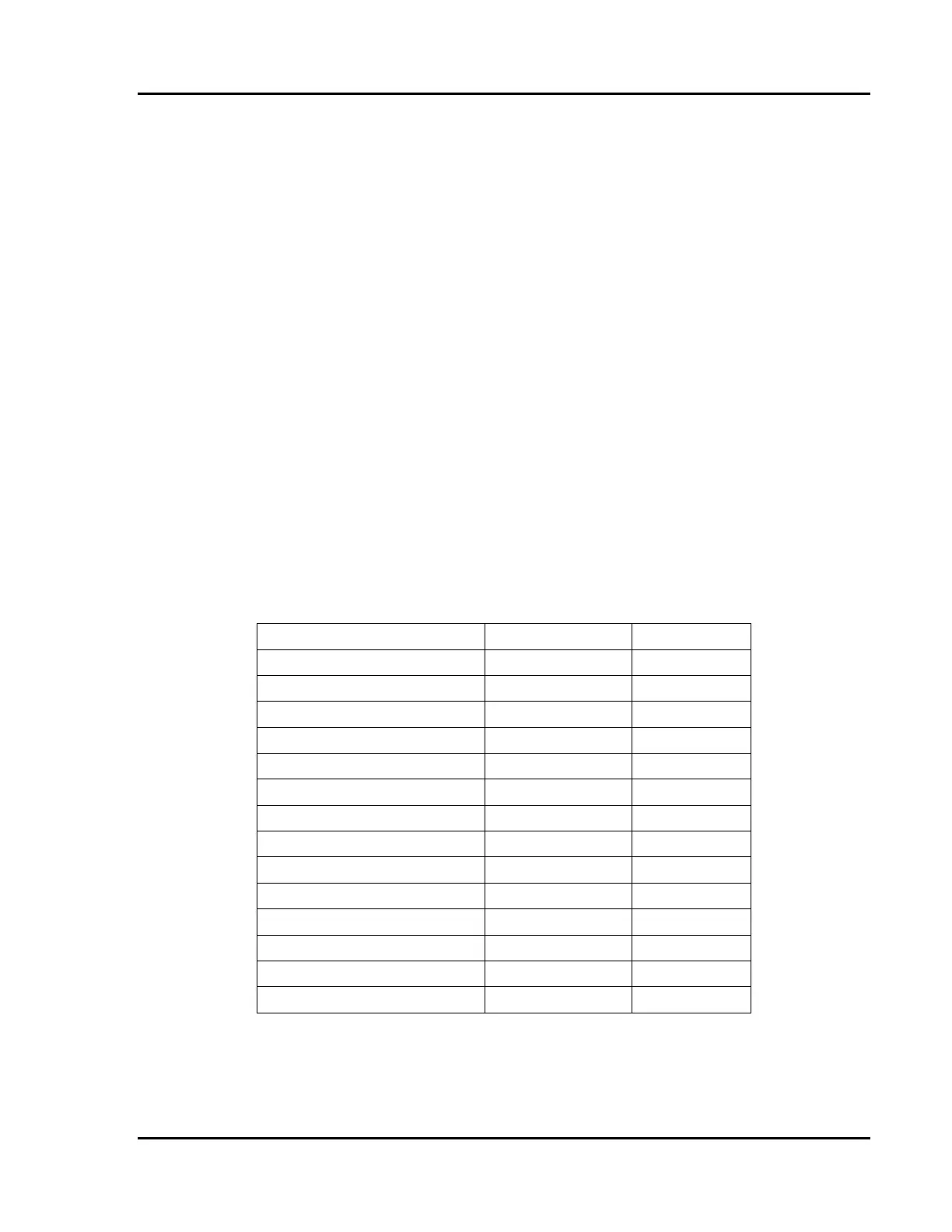

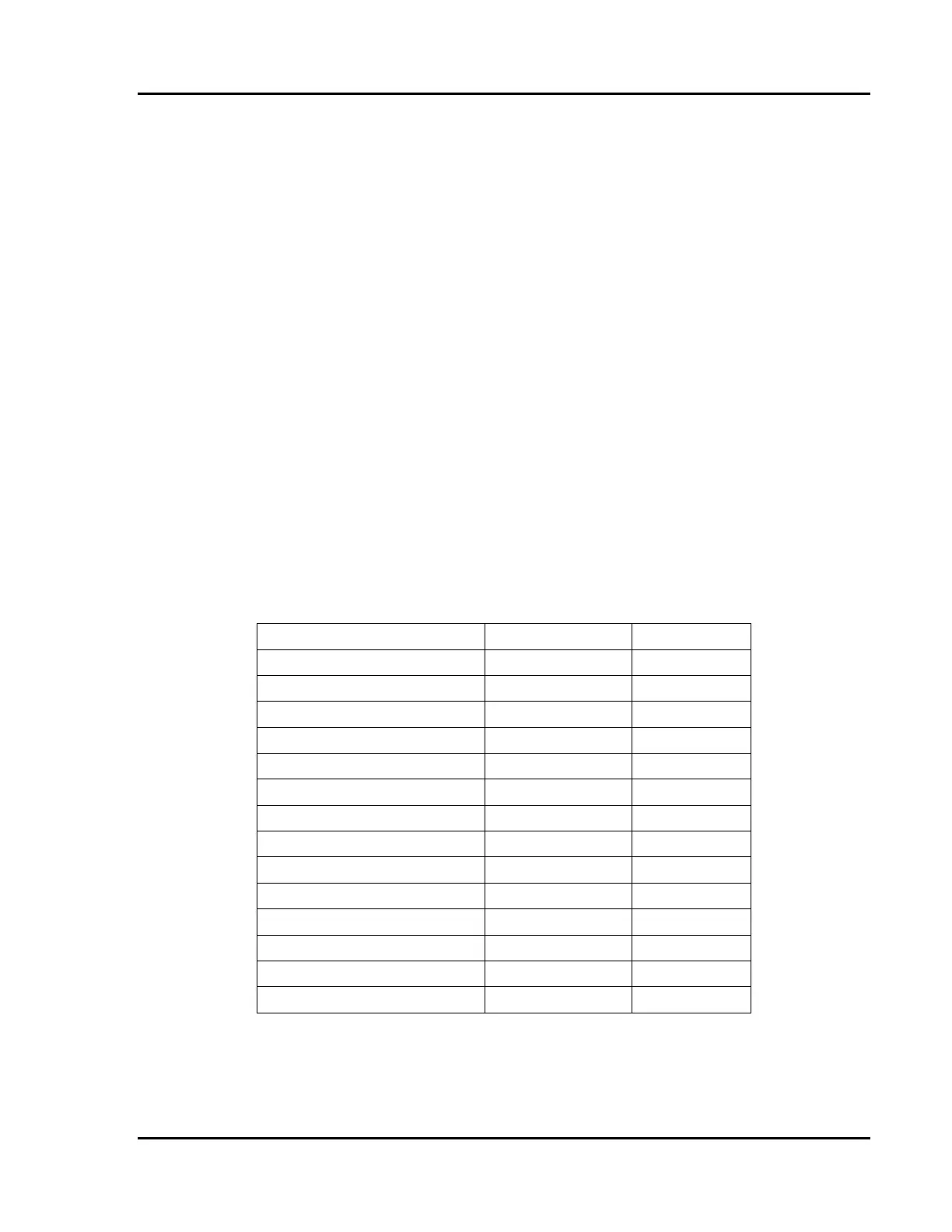

TABLE 3-2 COLUMN SOLENOIDS

Function Solenoid Valve Side

Tilt Up Y11 A

Tilt Down Y12 B

Trendelenburg Y21 A

Reverse Trendelenburg Y22 B

Height Up Y31 A

Height Down Y32 B

Kidney Up Y41 A

Kidney Down Y42 B

Back Up Y51 A

Back Down Y52 B

Leg Up Y61 A

Leg Down Y62 B

Leg Compensation Y63 A

Leg Compensation Y64 B

Loading...

Loading...