540

PROPULSION SYSTEMS

Studio ti 03312 540-04usa

146

8

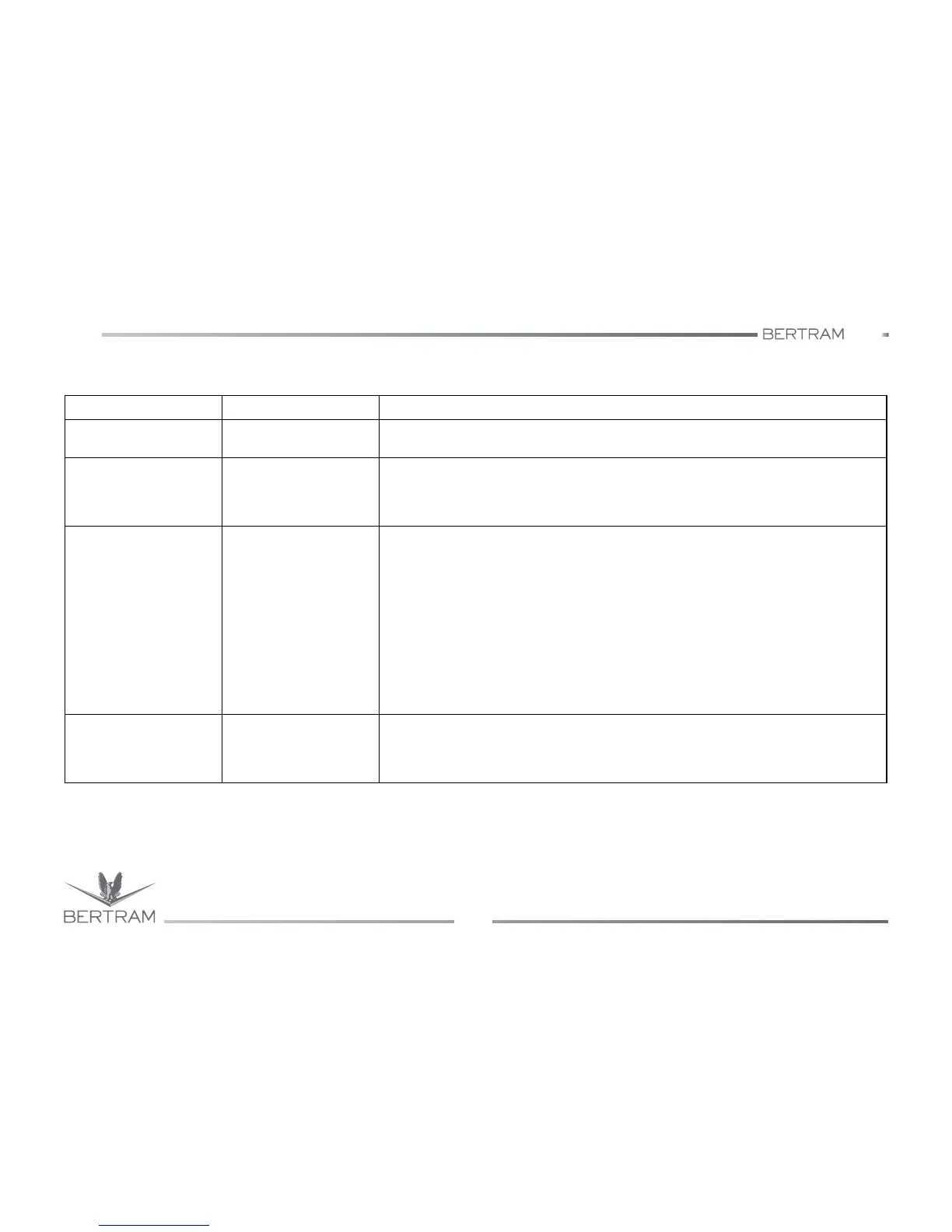

8.9 PROPULSION ENGINES MAINTENANCE

Item Maintenance Notes and precautions

Alternator Check Check that alternator and battery charger work correctly. If the batteries are charged

correctly, the ammeter value must be very close to the 0. All batteries must be kept charged.

Alternator belt Inspection

Adjustment

Replacement

To optimize the engine performance, check if the belt is worn out or cracked. Check the belt

tension. Adjust the tension of the belt to reduce slipping. A possible slipping shortens the

belt life.

Read carefully the service manual supplied by the manufacturer.

Cooling liquid Draining

Washdown

Filling

Check

Addition

Additional additive (SCA)

Clean the cooling system and wash it before the service interval recommended.

Stop the engine and let it cool down. Unlock the filling plug slowly to release the pressure,

then remove it.

Open the drain valve (if installed). If the cooling system is not equipped with this valve,

remove the drain plugs and drain the coolant.

Fill the cooling system with long life coolant (ELC). For further details about cooling system

specifications, see the instruction manual.

Unlock the plug of recovery tank slowly to release the pressure, then remove it.

Pour the long life coolant (ELC) into the proper recovery tank up to flush reference “COLD

FULL”. DO NOT fill the tank beyond above mentioned level.

Clean the recovery tank plug and fit it. Start the engine. Check for leaks in the cooling

system and if the operating temperature is correct.

Coolant temperature

controller

Replacement Replace the water temperature controller before it fails. This is a suggested preventive

maintenance practice. The controller replacement avoids possible unforeseen down-times.

A water temperature controller that fails into partial open position, can cause overheating or

excessive cooling of the engine.

Loading...

Loading...