540

GETTING UNDERWAY

Studio ti 03312 540-04usa

42

4

4.4 STARTING THE ENGINES

Refer to the AT THE HELM and INSTRUMENTATION AND

EQUIPMENT chapters for the location of all engine controls and gauges.

Carry out the necessary daily maintenance before starting the engines.

Check the engine room. This check can avoid following remarkable

repairs. For further information refer to the Use and Instruction Manual

delivered by the engine Manufacturer.

− The engines can have a longer life if you carry out a complete

inspection before start-up. Check following items: oil leaks, coolant

leaks, dirt build-ups. Remove dirt build-ups and repair if necessary.

− Check if cooling system hoses are cracked or show loose clamps.

− Check if alternator drive belts are cracked, broken or damaged.

− Check for the presence of loose wire connections, or worn out wires.

− Check the fuel quantity. Drain water from separator. Open the fuel

supply valve.

Oil level check

Check engine oil level only after the engine has cooled down.

− Pull out dipstick and wipe it with a clean, lint free rag.

− Place it back up to retainer.

− Pull out dipstick again.

The oil level should be between the two notches “ADD” and “FULL” of the

dipstick and must never drop below the lower notch. Add oil as

necessary.

NOTICES

Before starting the engine, check fuel level, coolant level and engine oil

level. In case of need, fill with fuel, coolant and oil mix.

S

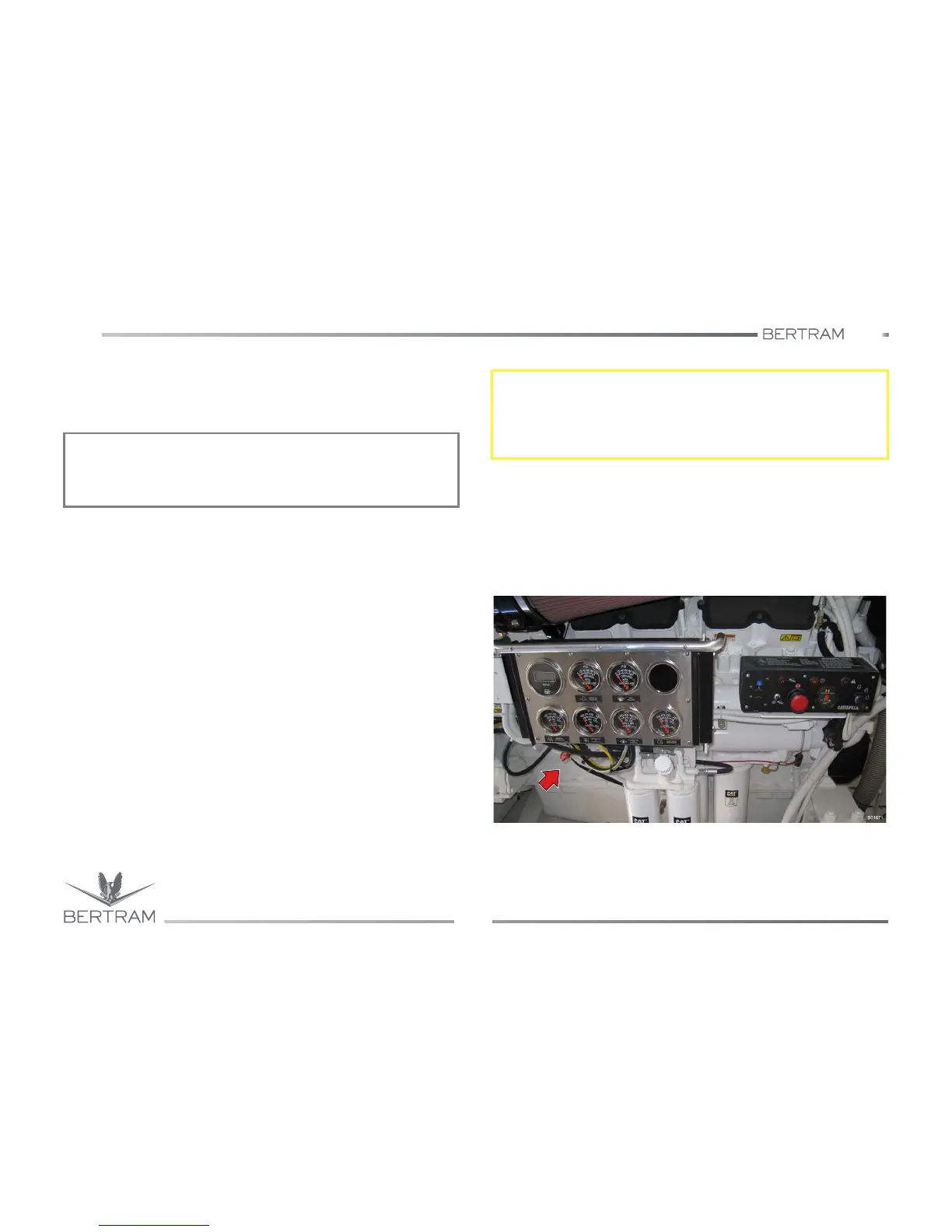

CAUTION

Open all valves in the fuel supply line before starting the engine, in order

to prevent fuel high pressure. This pressure can damage the filter

housing or cause other kinds of damage.

Loading...

Loading...