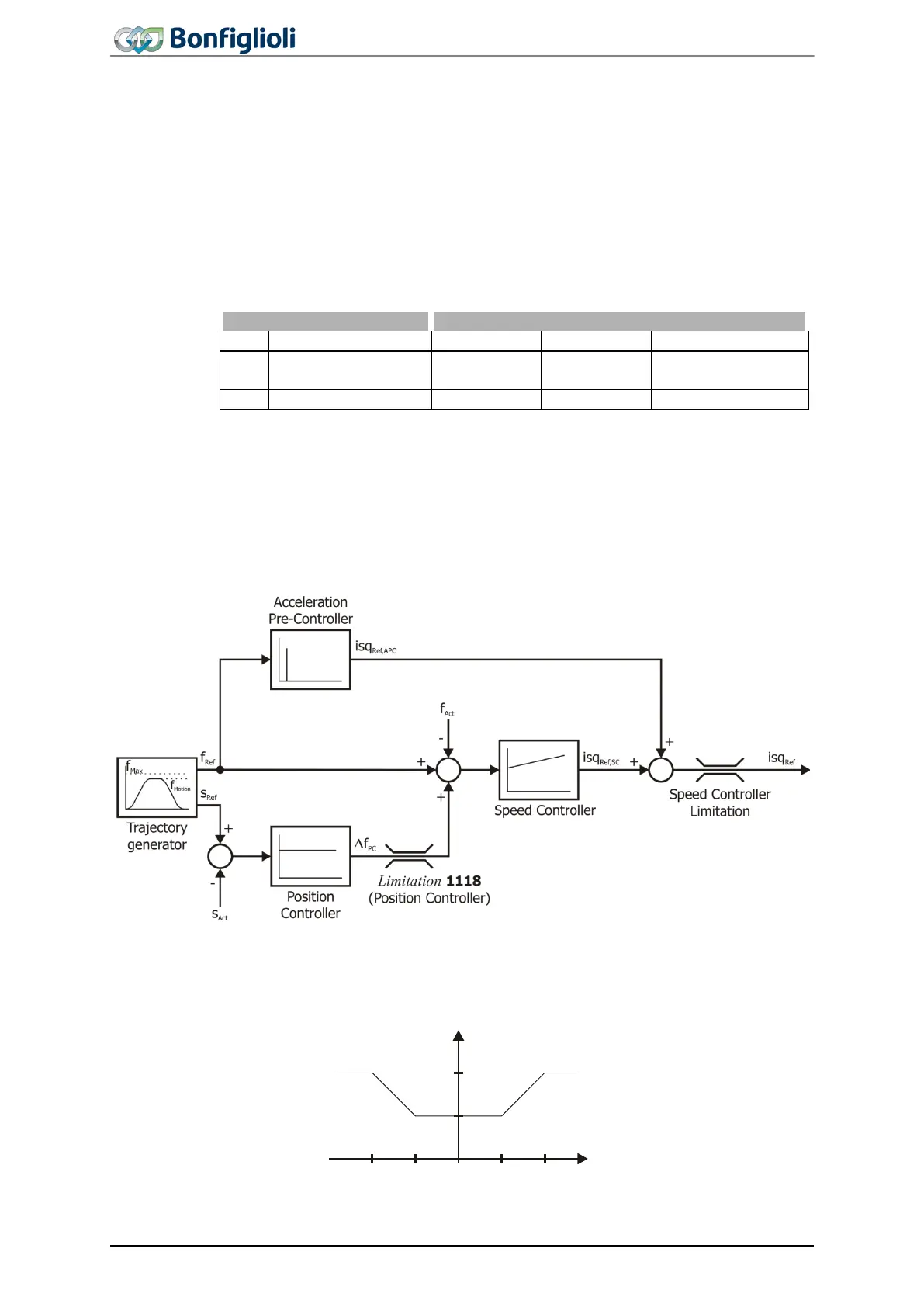

10.2.5 Position Controller

The position controller evaluates the positioning operation (target/actual position)

and tries to control the drive such that it comes as close as possible to the specifica-

tions. For this purpose, an additional frequency is calcu

lated for compensation of

position deviations. By setting the corresponding parame

ter, this frequency can be

limited. The parameter settings of the position controller determine how quick and

to what extent position deviations are to be compensated.

Via Time Constant

1104, you can define the maximum time in which the position

deviation is to be compensated.

Via parameter

Limitation 1118, you can define to which value the speed is limited

for compensation of the position deviation.

1104 Time Constant 0.00 ms 300.00 ms

2)

1)

Factory parameter setting Configuration 30 = 240 or 540

2)

Factory parameter setting Configuration 30 = 440

Example:

Position deviates by 1 motor shaft revolution, time constant is set to 1 ms. The pos

i-

tion controller will increase the motor frequency by 1000 Hz in order to compensate

the position deviation. Parameter Limitation 1118 must be set accordingly.

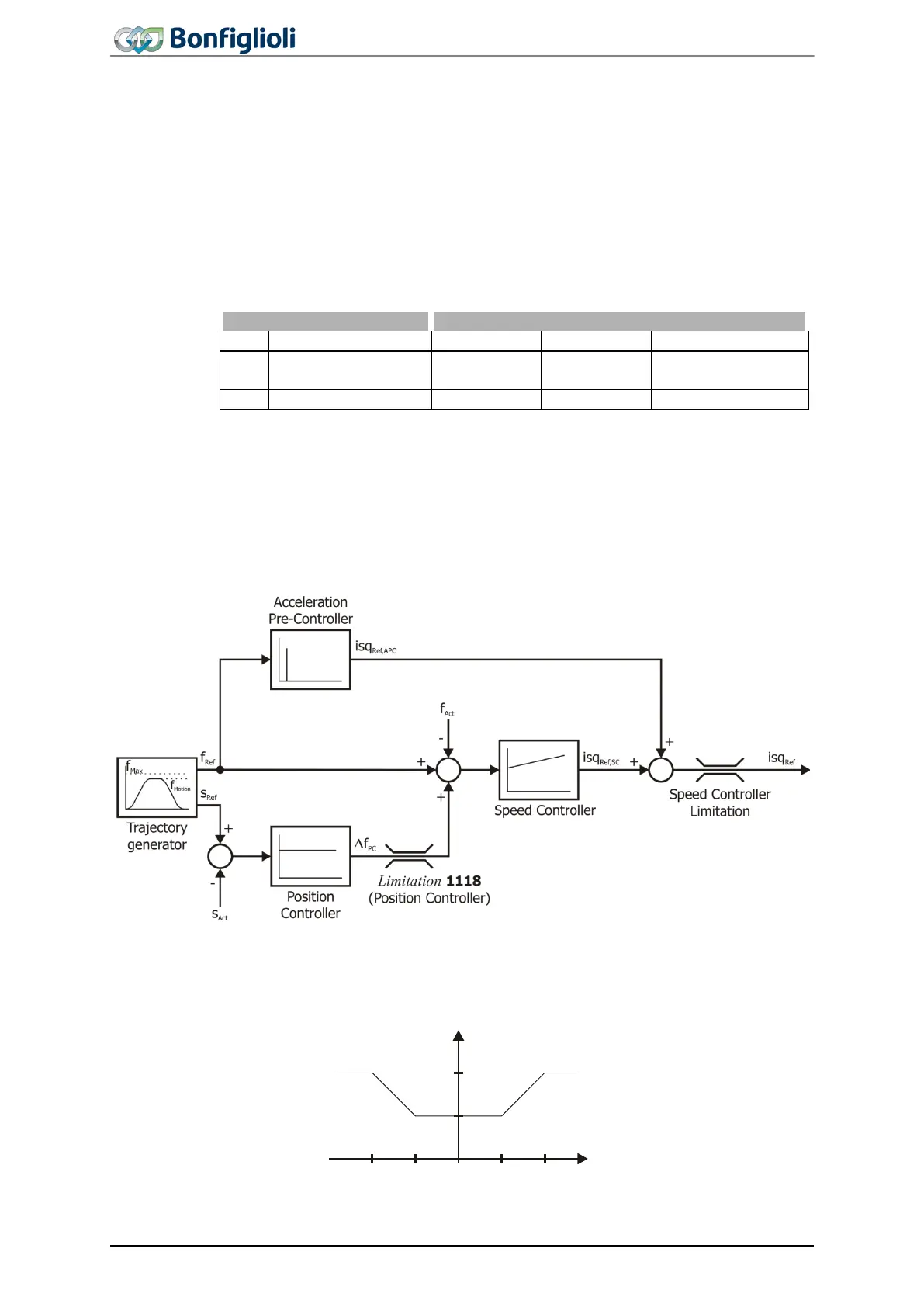

In order to avoid oscillations of the drive while it is at standstill, amplification is re-

duced to 50 % of the parameterized value for small position deviations.

Amplification [%]

Control deviation

of position [°]

0.25-0.25 0.00

50

100

0.50

-0.50

60

ACU

Modbus/TCP 10/13

Loading...

Loading...