9E-926 46 SmartControl™ Meter & TouchPoint™

Operation Instructions

4. Operation

4.1 Understanding Basic Parts

4.1.1 Milk Meter

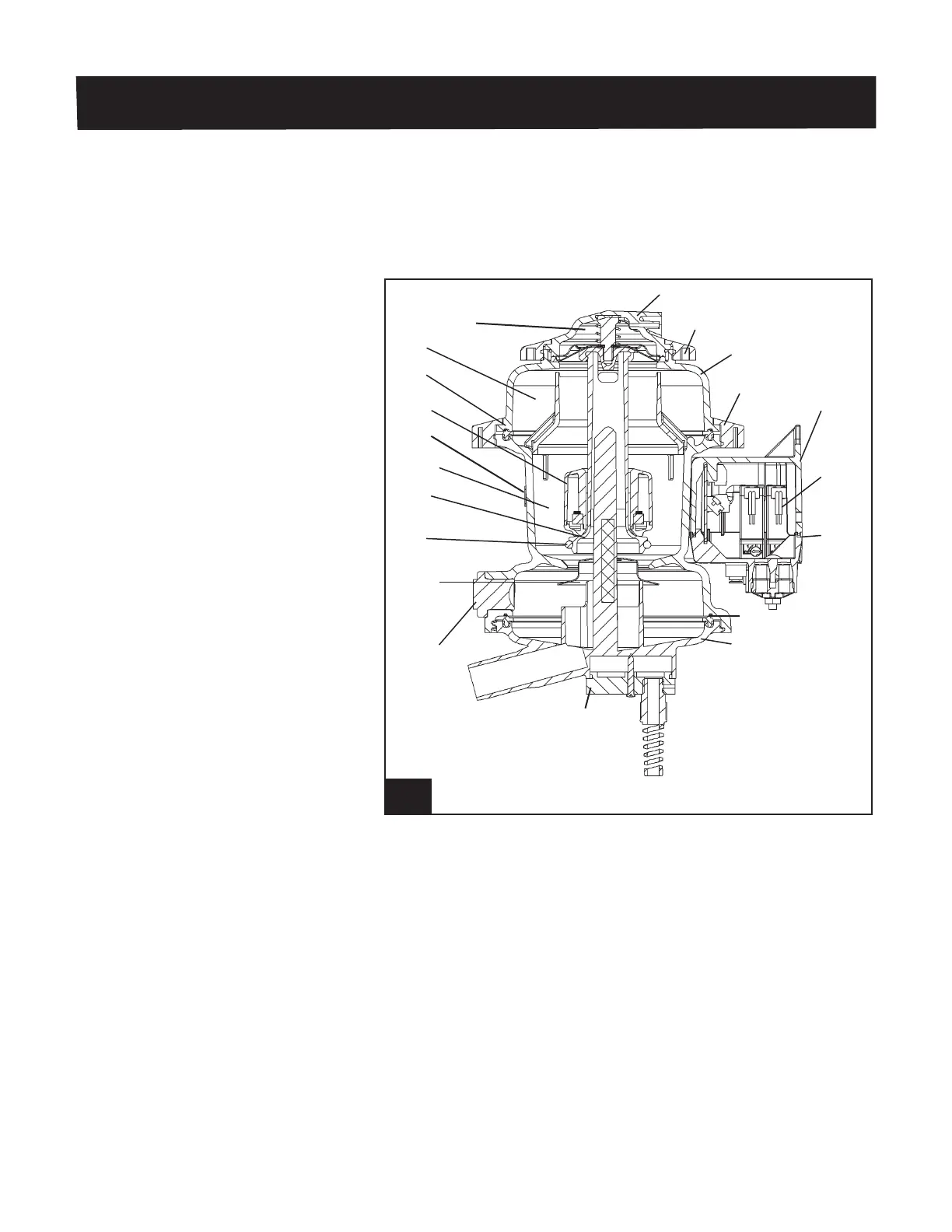

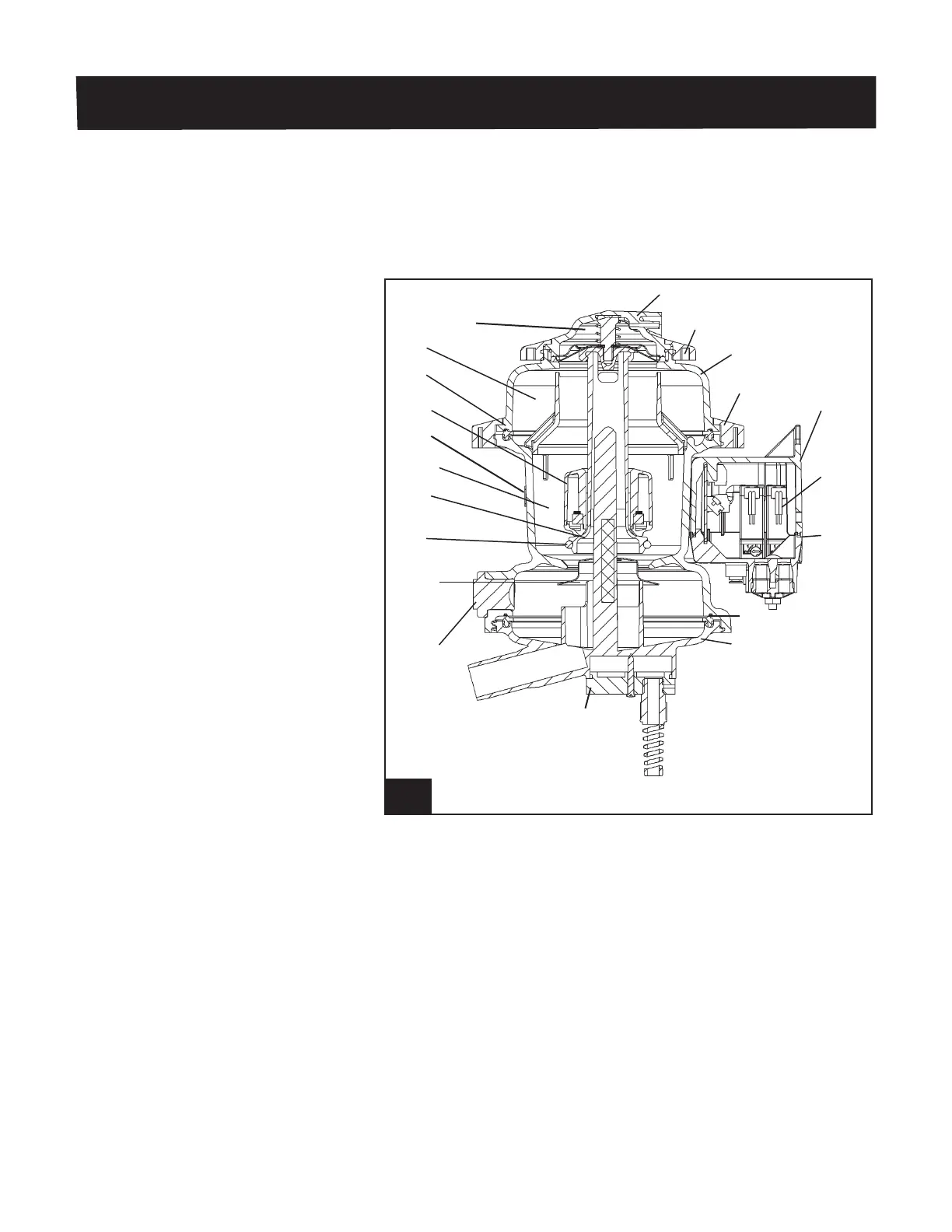

The milk meter measures a cow’s milk production, milking time

and conductivity—all of which it sends to a SmartDairy Control-

ler (if used). The meter consists of the parts shown in Figure

30.

30. Section view of meter l925_11

Top Cap

Cap Lock

Ring

Inlet

Section

Inlet Lock

Ring

Mounting

Box

Solenoid

Valve

Junction

Box Cover

Gasket

Outlet

Section

Conductivity

Probes

(Not Shown)

Level Sensing

Probe

Sampler

Plug

Wash

Deector

Plunger

Seal

Plunger

Measuring

Chamber

Mounting

Strap

Float

Assy

Gasket

Bafe

Diaphragm and

Spring Assy

Milk meter operation begins when milk and air from the claw

enter the inlet of the meter. A bafe in the upper section of the

meter separates the air from the milk and directs the milk down

the inside wall of the measuring chamber (to reduce foaming),

while air escapes through the air bypass. This separation al-

lows the meter to maintain a stable vacuum level.

Attached to the top of the inlet is a small chamber containing

a diaphragm and spring assembly. These parts raise and lower

the plunger to empty and ll the chamber as determined by the

electronic control.

The measuring chamber contains a seat, a plunger with rubber

sealing surface and a sealed oat with a magnet inside. This

chamber is transparent and cylindrical.

Loading...

Loading...