112

ELECTRICAL AND IGNITION

FLYWHEEL AND STATOR SERVICING

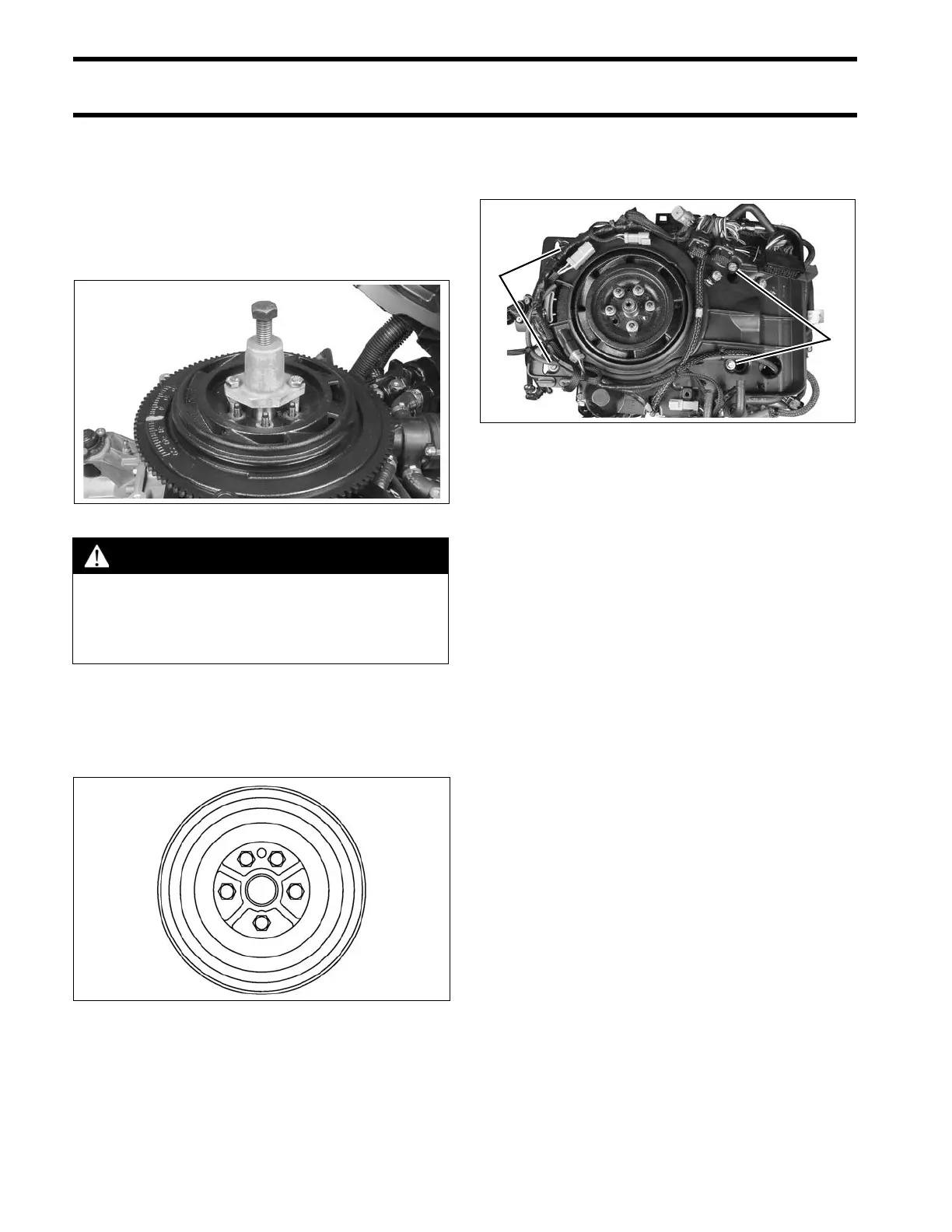

Use Flywheel Puller Adaptor Kit, P/N 5007181,

and Flywheel Service Kit, P/N 434649, to position

flywheel on top of crankshaft. Align the alignment

hole in flywheel with alignment pin of crankshaft.

Turn center screw counterclockwise to lower fly-

wheel onto crankshaft. Remove tools from the fly-

wheel and crankshaft.

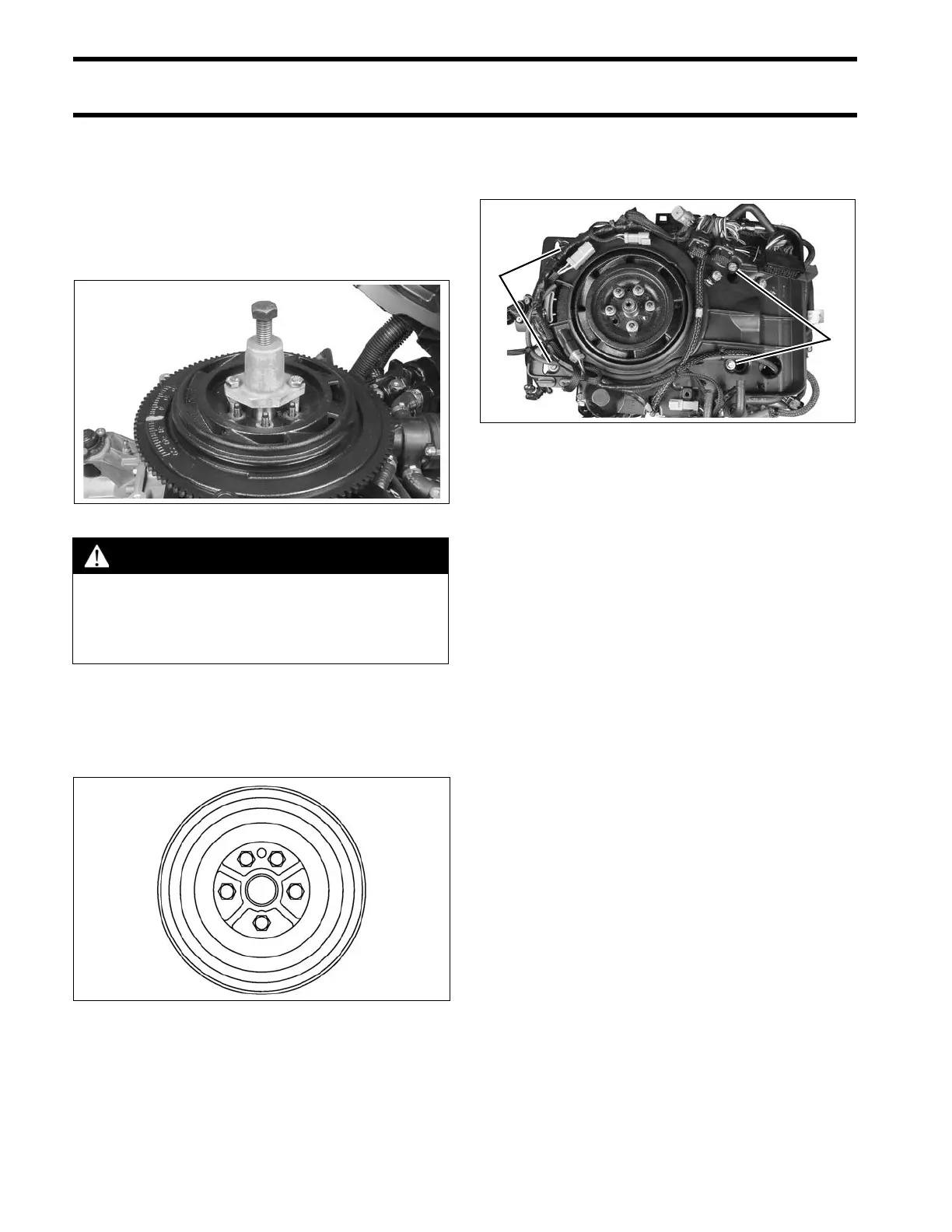

Apply Triple-Guard grease to studs and install five

new flywheel retaining nuts and washers. Follow

torque sequence below. Tighten nuts to a torque

of 30 to 32 ft. lbs. (40.5 to 43 N·m).

Install the electrical harness base and secure with

four screws. Tighten screws to a torque of 60 to

84 in. lbs (7 to 9.5 N·m).

Reconnect the stator connector, two port side trim

system connectors, port engine temperature sen-

sor, and the port ground terminal.

Reconnect the crankshaft position sensor, throttle

position sensor, air temperature sensor, and oil

pump electrical connectors.

Install the EMM. Refer to EMM SERVICING on

p. 68.

005383

CAUTION

To avoid damage to flywheel magnets, or

injury to fingers, Flywheel service kits,

P/N 434649 and P/N 5007181, must be

used to remove or install the flywheel.

Flywheel Torque Sequence DRC3737

1. Harness base screws 005378

Loading...

Loading...