305

GEARCASE – STANDARD ROTATION

GEARCASE ASSEMBLY

12

Propeller Shaft Bearing Housing

and Gear Installation – “M2” Type

IMPORTANT: The propeller shaft bearing hous-

ing on the “M2” type gearcases is PRESSED into

the gearcase housing.

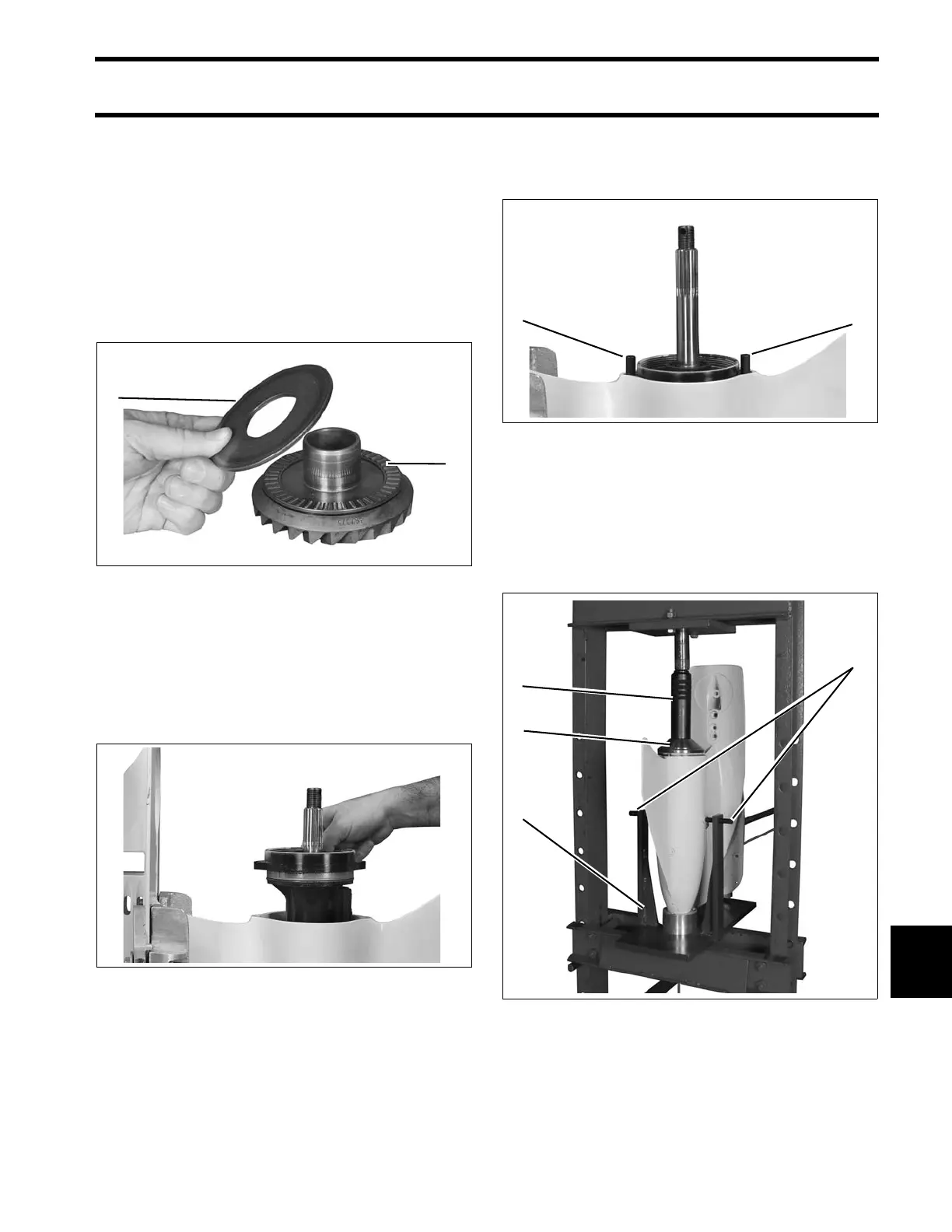

Oil and install thrust bearing and thrust washer on

hub of reverse gear. Slide the gear assembly onto

the propeller shaft until it engages the pinion gear.

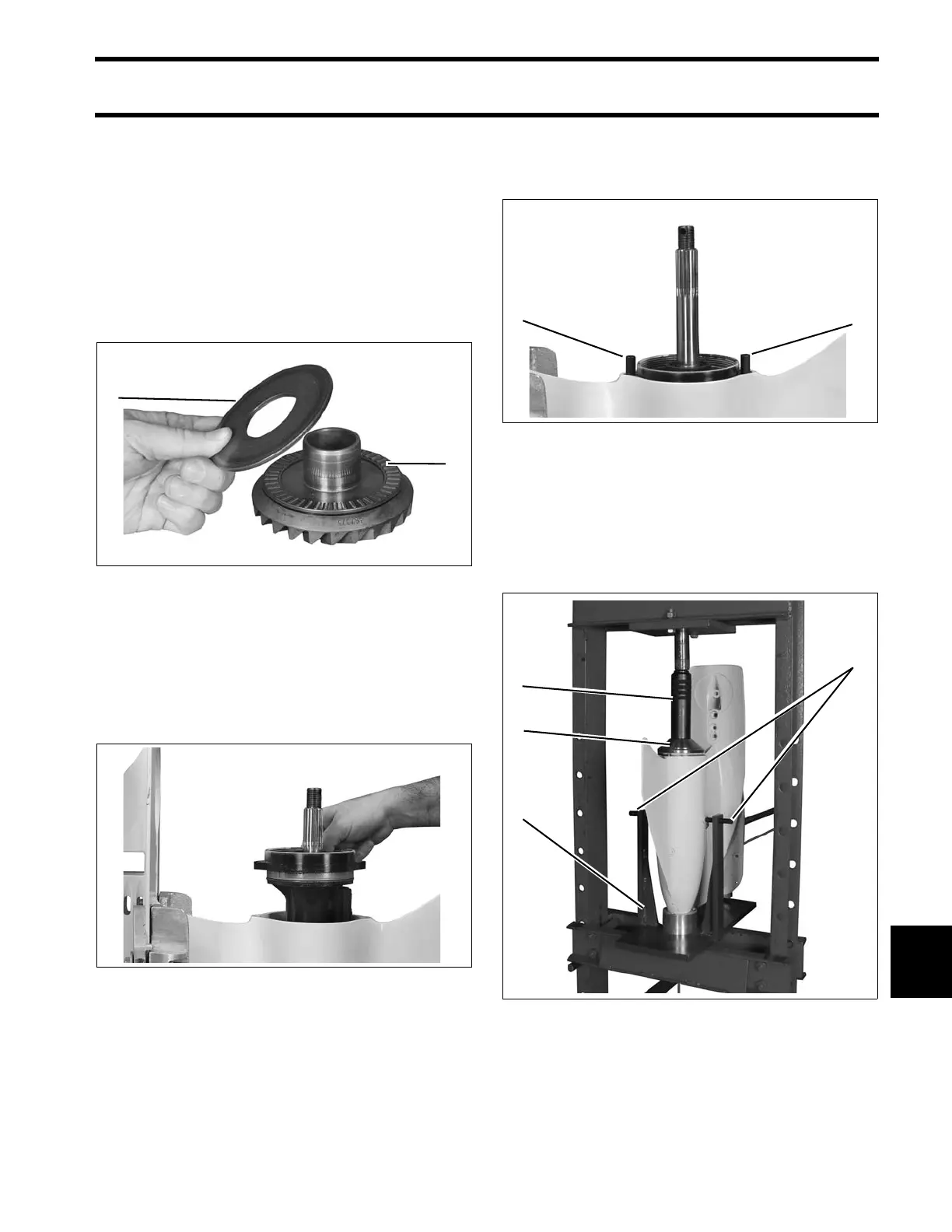

Lightly apply Triple Guard Grease to new bearing

housing O-rings. Install O-rings in grooves in the

housing. Grease the machined side surfaces of

bearing housing.

Place bearing housing in gearcase.

Align retaining holes in bearing housing with

screw holes in gearcase. Thread Alignment Pins,

P/N 354140, into gearcase.

Use Installer Handle, P/N 345822, Propeller Shaft

Bearing Housing Installer, P/N 354057, Gearcase

Fixture, P/N 354059 and an appropriate floor

press (10 ton or greater) to install housing into

gearcase. Align and level gearcase assembly in

fixture as shown. Secure fixture to floor press.

1. Thrust bearing

2. Thrust washer

006925

006846

1. Alignment pins 006926

1. Gearcase fixture, P/N 354059

2. Vertical alignment screws

3. Handle P/N 345822

4. Housing installer P/N 354057

006927

Loading...

Loading...