Installation

30 H148850_3_003

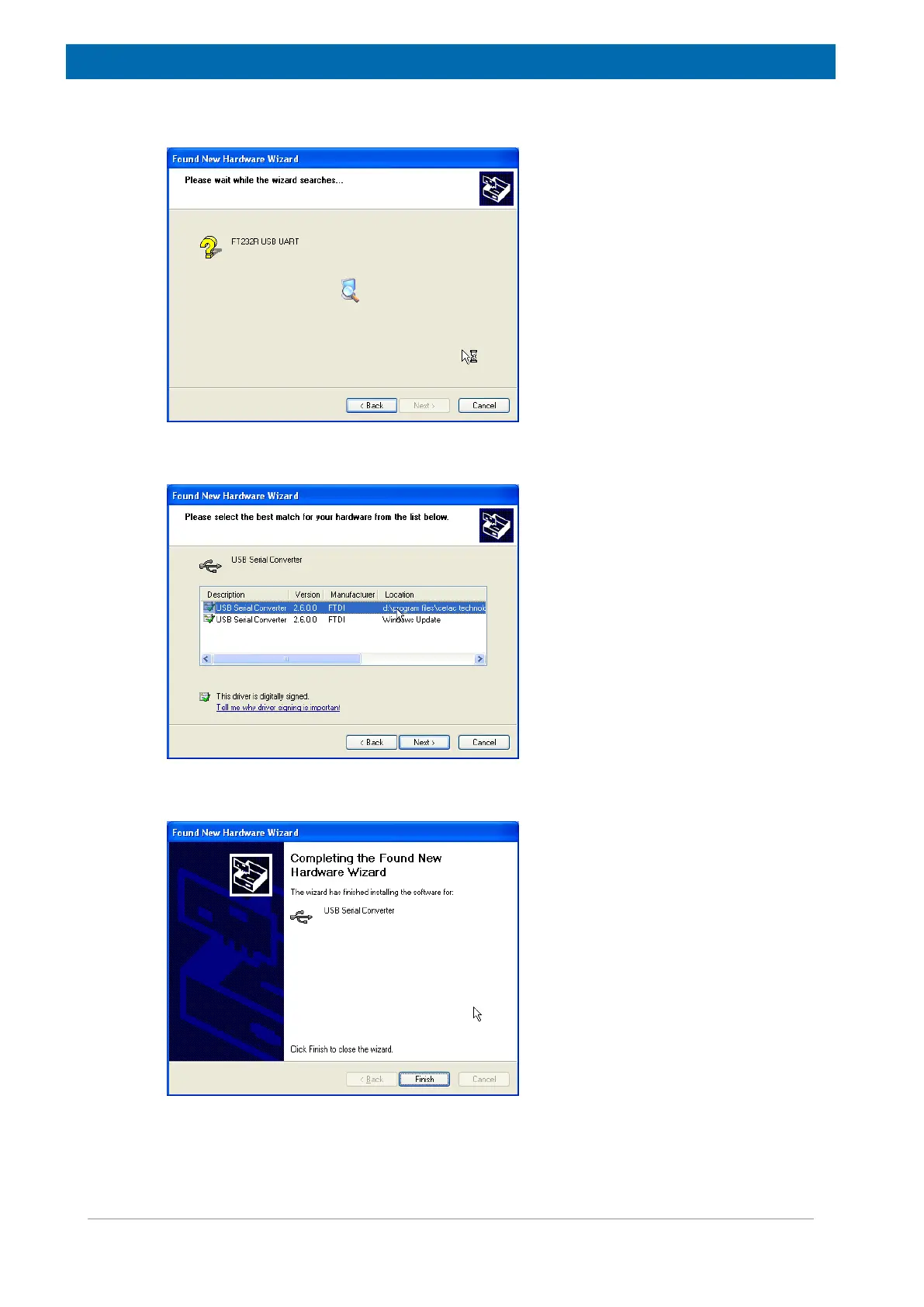

• Wait while the computer searches the media.

Figure6.10: Searching for the Driver

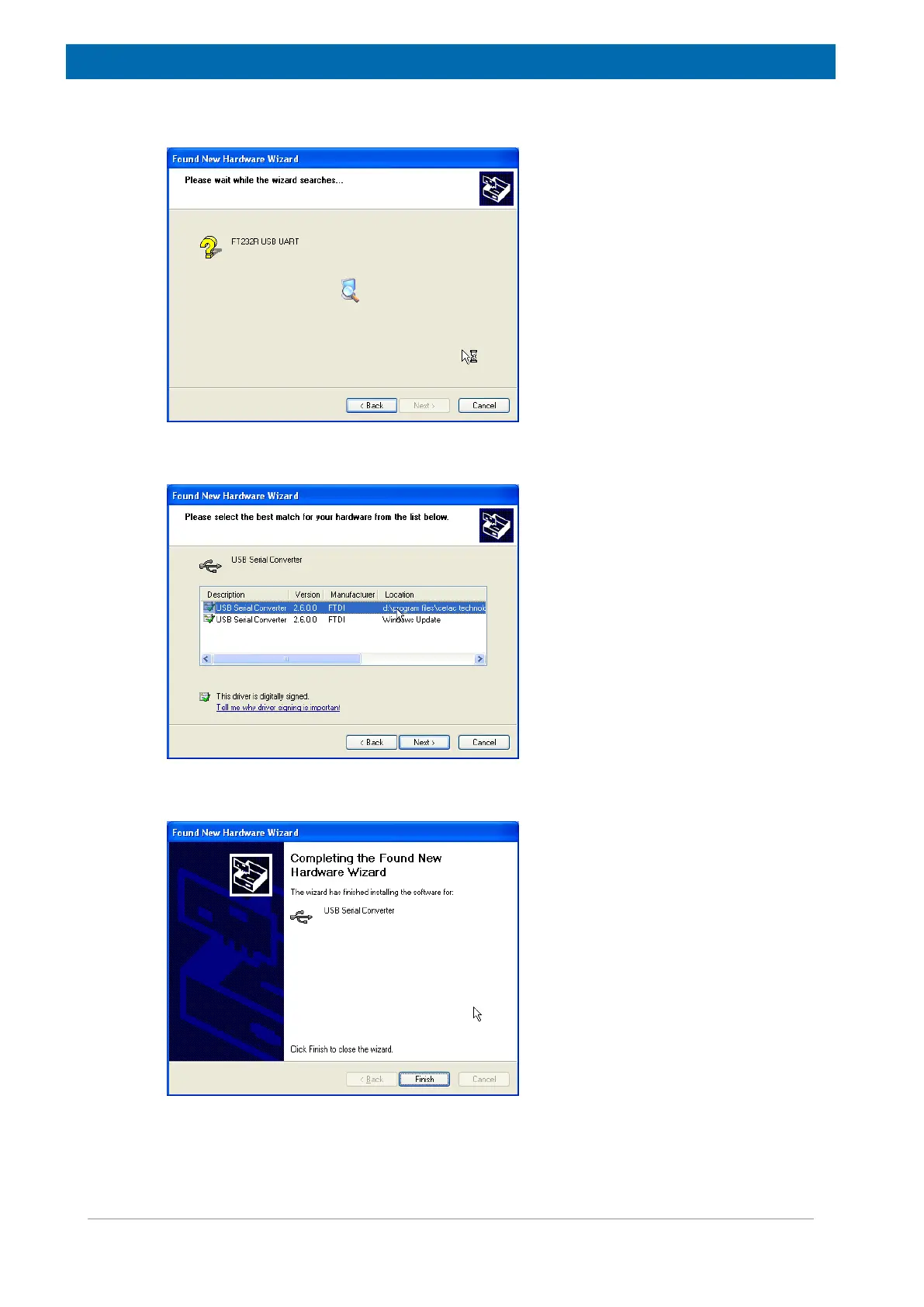

• When the driver is found, select it and click Next.

Figure6.11: Selecting the Driver

• The driver installation is complete.

Figure6.12: Driver Installation is Complete

Loading...

Loading...