SECTION 17 - TORQUE CONVERTERS 3

1. POWERSHUTTLE TORQUE CONVERTER

1.1 DESCRIPTION AND OPERATION

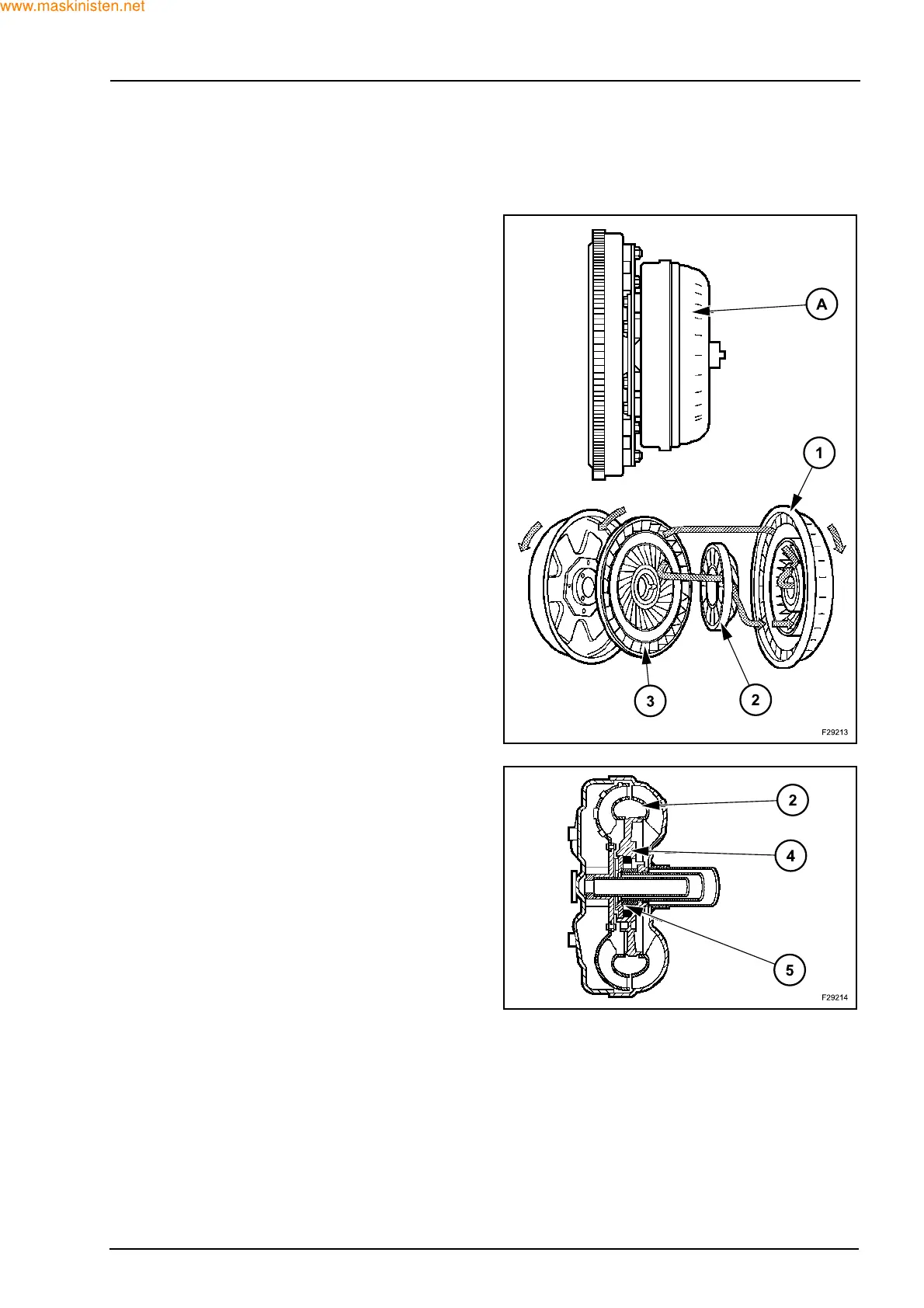

The torque converter is the connection between the

engine and the transmission and is hydraulically ac-

tuated. The main parts of the torque converter (A)

are the impeller (pump), the turbine, the stator and

the front and rear covers. The impeller is integral

with the rear cover and is driven by the engine fly-

wheel by means of a drive plate. The stator, is

splined to a stationary shaft (stator support) through

a one-way clutch that permits the stator to rotate

only in the same direction as the impeller. All of the

converter parts are enclosed in an oil-filled housing.

The front and rear cover, being welded together,

form the housing. The turbine (2), splined to the front

input shaft, is splined to a stationary shaft (stator

support) through a one-way clutch that permits the

stator (3) to rotate only in the same direction as the

impeller (1). All of the converter parts are enclosed

in an oil-filled housing. When the engine is running,

the oil in the converter flows from the impeller (1) to

the turbine (2) and back to the impeller through the

stator (3). This flow produces a maximum torque in-

crease. When enough oil flow is developed by the

impeller, the turbine begins to rotate, driving the

front input shaft. The torque multiplication gradually

decreases as turbine speed approaches impeller

speed, and becomes 1 to 1 when the turbine is being

driven at nine tenths impeller speed.

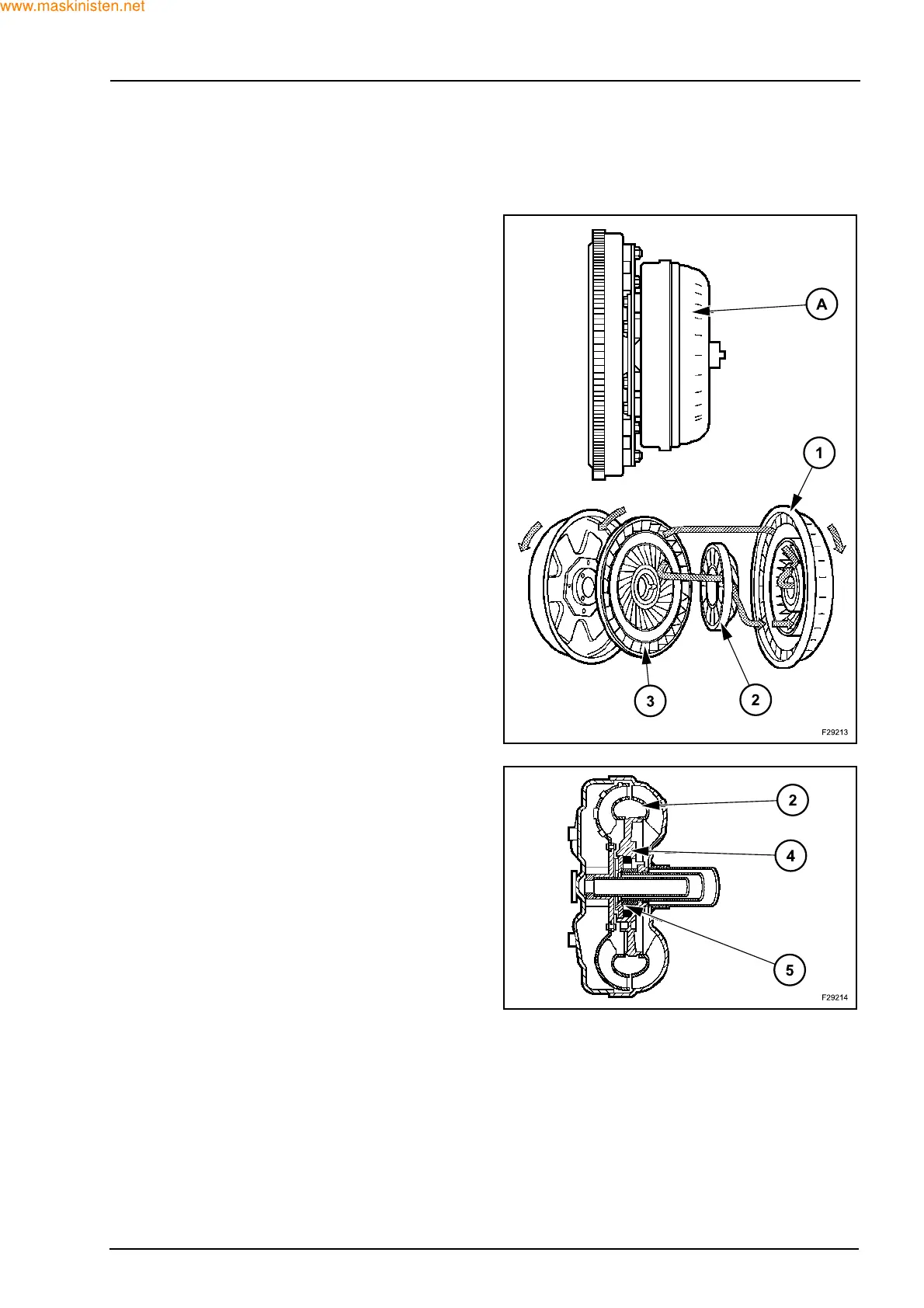

When the turbine (2) is rotating at approximately nine

tenths impeller speed, the converter stops multiplying

torque because the oil is now acting on the rear face

of the stator blades (4). The action of the oil on the

rear face of the stator unlocks the one-way clutch (5),

permitting the stator to rotate in the same direction as

the turbine (2) and impeller (1). Through this action

the converter becomes an efficient fluid coupling by

transmitting engine torque from the impeller to the tur-

bine. To achieve optimum operation the engine per-

formance, transmission ratios, hydraulic power

delivery and converter torque multiplication are all

“Matched” to provide the necessary vehicle drive

torque when required. When the turbine is rotating

less than nine tenths impeller speed (1), the converter

is multiplying torque through the action of the stator

(3). This action, produced by oil acting on the front

face of the stator blades, tends to rotate the stator in

the opposite direction of the impeller (1) and turbine

(2). However, the one-way clutch prevents this oppo-

site rotation and allows the stator to direct oil back to

the impeller, thereby producing torque multiplication.

Maximum torque multiplication is achieved when the

impeller is driven at stall speed and the turbine is sta-

tionary.

Loading...

Loading...