SECTION 50 - CAB HEATING AND AIR CONDITIONING 5

2. CAB HEATING

2.1 DESCRIPTION AND OPERATION

Cab heating

The cab is heated by a radiator mounted below the

cab seat, which is supplied hot water from the engine

coolant system. A blower motor mounted behind the

cab radiator is used to transfer the heat into the cab.

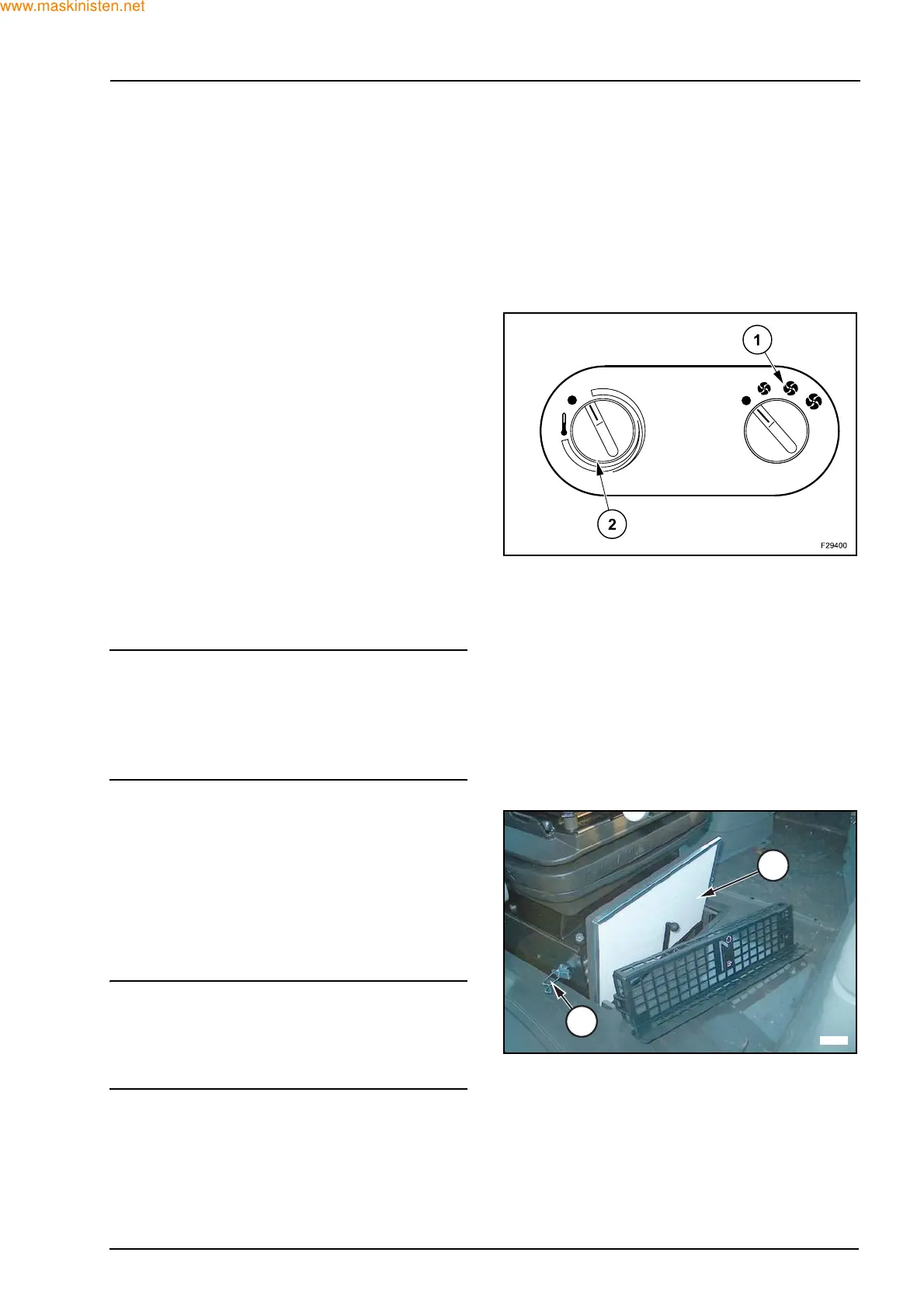

Heater blower control

The three speed blower is controlled by switch (1)

mounted in the instrument console to the right of the

cab seat. Turn the switch clockwise to the first posi-

tion for slow speed. Further rotation of the switch in

a clockwise direction selects medium and fast

speeds. The blower draws outside air from beneath

the cab floor and through a filter medium into the

cab.

Temperature control

The temperature of the air from the radiator is adjust-

ed by rotation of the control knob (2) which opens or

closes the radiator valve increasing or decreasing

the water flow as required. Turn the control clock-

wise to increase the temperature of air from the

heater and counter clockwise to reduce the temper-

ature.

SWARNING

The cab air filters are designed to remove dust from

the air but may not exclude chemical vapour. When

working in an enclosed area ensure there is ade-

quate ventilation as exhaust fumes can suffocate

you.

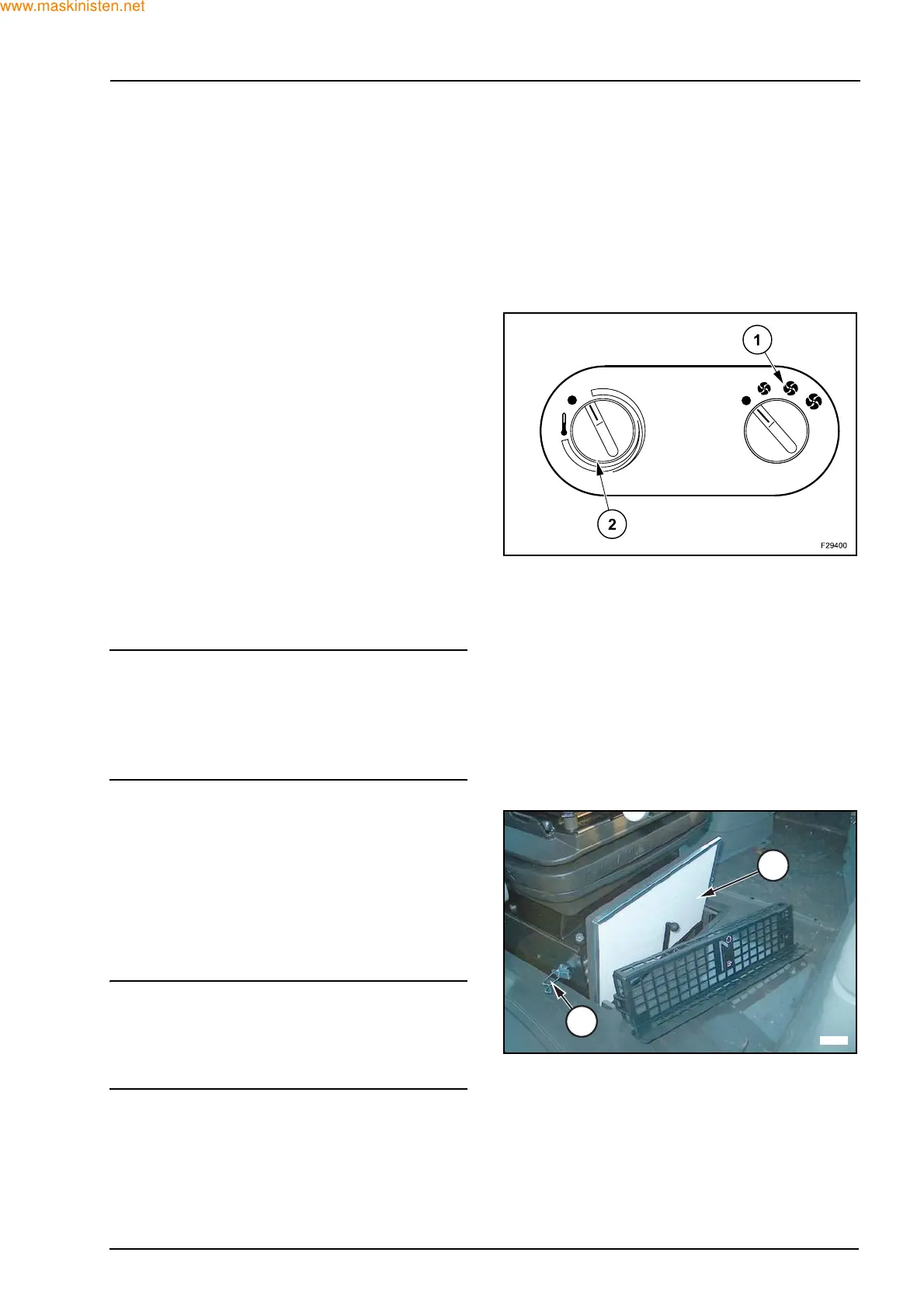

Cab air filter

Before servicing the air filter situated under the driv-

ers seat, switch off the blower and close all windows

and one door. Forcibly close the other door. The re-

sulting back pressure will dislodge loose dirt from

the underside of the filters. To remove the filter (3)

release the retaining straps (4) and remove the filter

element. Ensure the element, and sealing faces are

not damaged on removal.

IMPORTANT: in humid conditions, such as occur on

most early mornings, do not switch on the blower pri-

or to servicing the filters. Damp particles drawn into

the filter may solidify and prove difficult to remove

without washing.

The filter element is made of specially treated paper

with a sealing strip bonded to the outer face.

Clean this element by blowing with compressed air

from the clean side through to the dirty side. The

compressed air should not exceed 2 bar and the air

line nozzle should be at least 300 mm from the ele-

ment.

F29325

3

4

Loading...

Loading...