46 SECTION 50 - CAB HEATING AND AIR CONDITIONING

3.6 EVACUATING THE SYSTEM

IMPORTANT: a system in which the refrigerant has

been recovered to facilitate repairs, must be evacu-

ated before new refrigerant is installed.

Air and moisture are removed by evacuating the

system using a vacuum pump.

The automatic recycling, recharge and evacuation

stations or evacuating and charging stations availa-

ble throughout the air conditioning industry incorpo-

rate a vacuum pump within the assembly. If this type

of equipment is not available a separate vacuum

pump and manifold gauge set must be used.

As the system is evacuated the boiling point of any

moisture within the system is similarly lowered. As

the vacuum increases, the boiling point decreases

to below that of the ambient temperature and, con-

sequently, the moisture is boiled away.

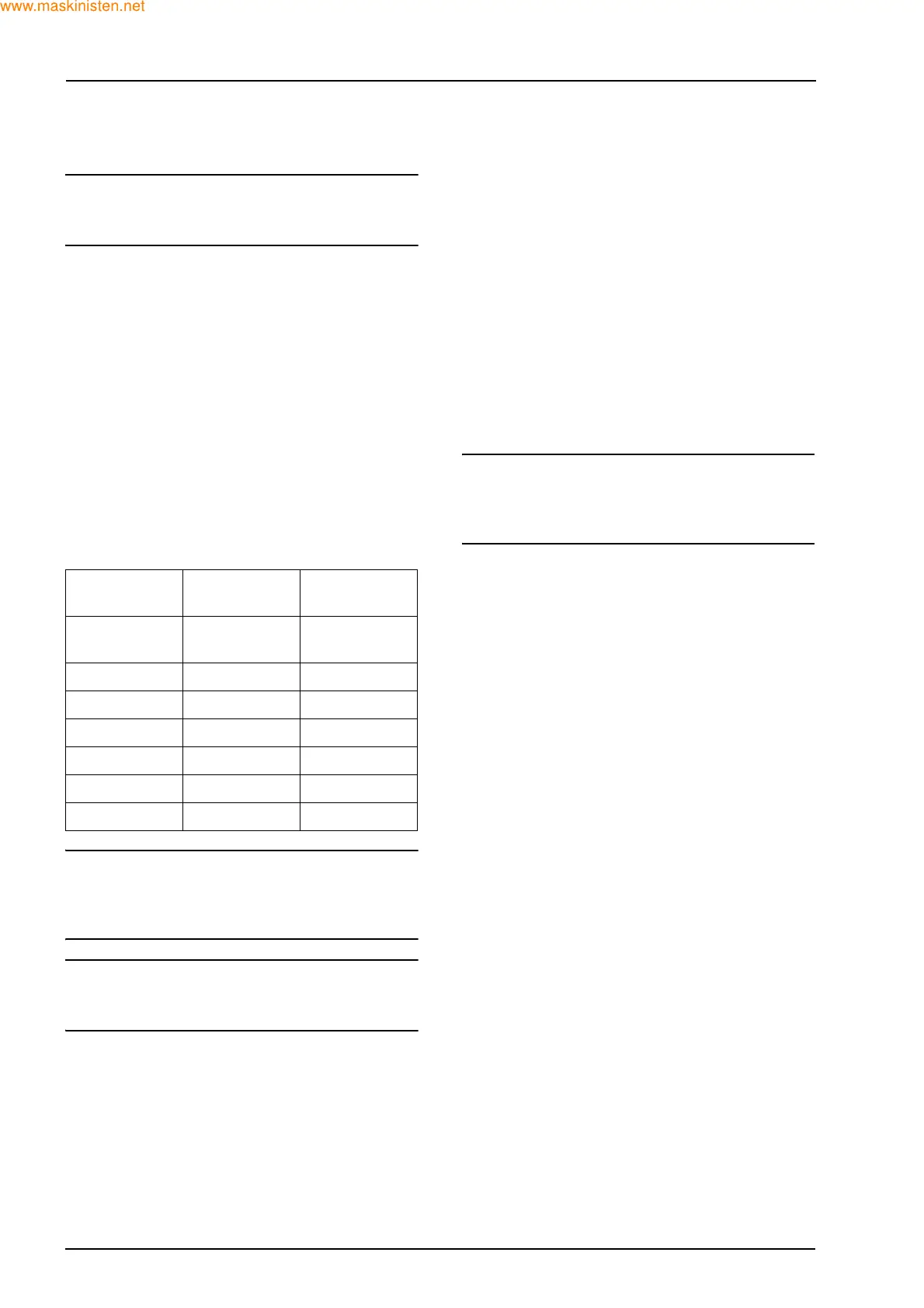

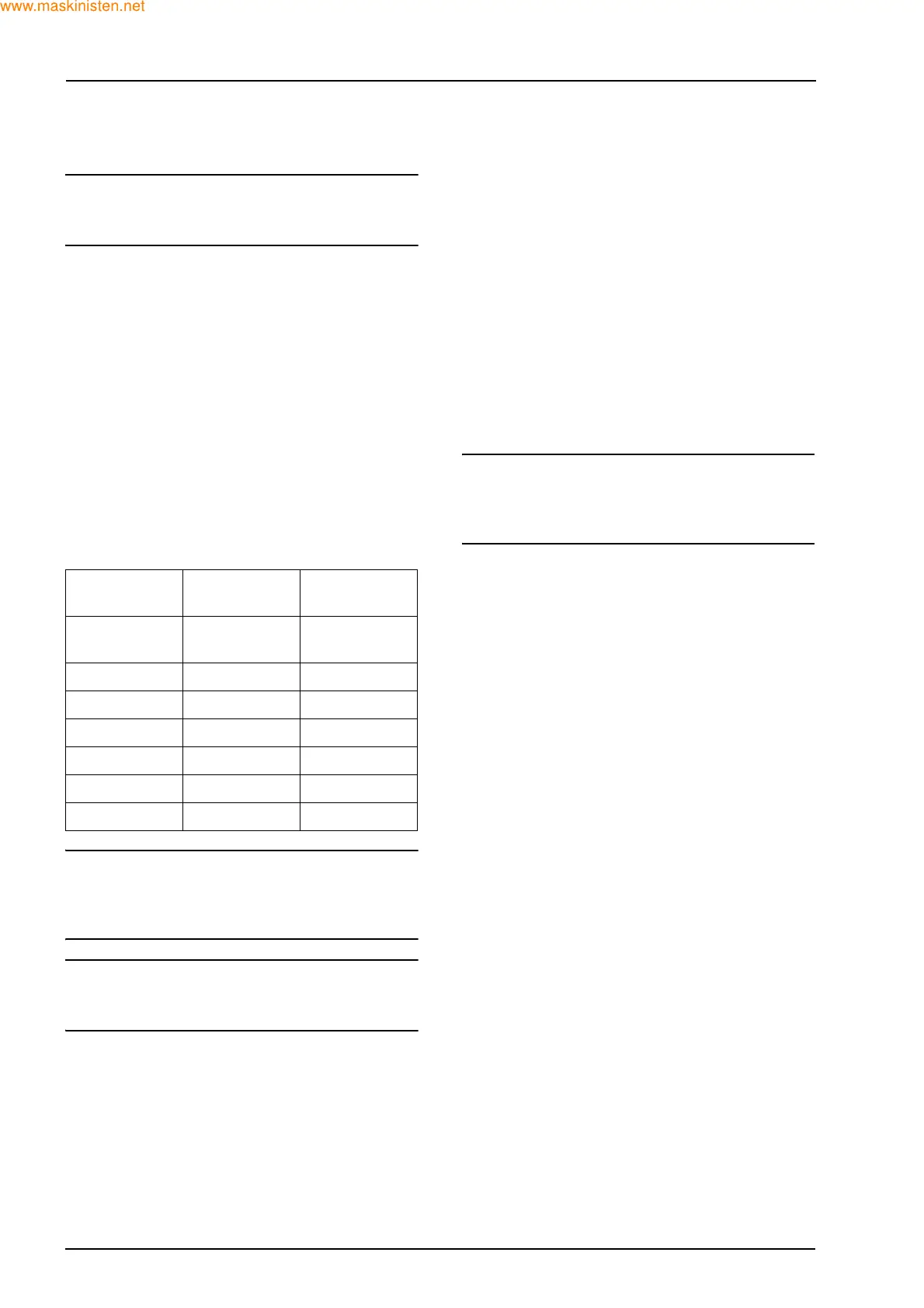

The relationship of system vacuum to the boiling

temperature at which the water vapour is removed

from the system is as follows:

NOTE: for every 305 m above sea level, the vacuum

gauge reading must be corrected by adding 2.54 cm

of mercury to compensate for the change in atmos-

pheric pressure.

IMPORTANT: be sure the system is completely dis-

charged as refrigerant will damage the vacuum

pump.

1. If the manifold gauge set is being used connect

the low and high sides of the manifold to the low

and high sides of the vehicle air conditioning

system as described for discharging the system.

Connect the manifold centre hose to the vacu-

um pump suction port as per the manufacturers

instructions.

Fully open both the low and high side gauge

shut off valves.

2. If a combined recovery/evacuation unit is to be

used attach the unit to the air conditioning sys-

tem in accordance with the manufacturers in-

structions. Be sure to read all installation and

operating instructions carefully before starting

the unit.

3. After starting the evacuation cycle, note the low

side gauge to be sure the system pulls down

into a vacuum.

4. Time the evacuation for a minimum of 30 min-

utes from the point when lowest vacuum is at-

tained.

5. Thirty minutes later when the low side gauge at-

tains the lowest steady vacuum, stop the evac-

uation process.

NOTE: the vacuum pump achieves ultimate vacu-

um with the vented exhaust valve closed. Do not

evacuate too quickly as oil may be drawn from the

system.

6. Check the system by closing the gauge shut-off

valves, turning the vacuum pump off and noting

the low side gauge reading. A loss of more than

5 cm of vacuum in 5 minutes indicates either a

leak or moisture in the system.

7. If the gauge needle remains stationary and the

vacuum is maintained for 3-5 minutes, close

both the high and low side manifold hand

valves, turn off and disconnect the centre hose

from the pump. The system is now ready for

charging.

8. If a leak is detected, charge the system with ap-

proximately 400 g of refrigerant, see charging

the system and locate the leak using a leak de-

tector.

9. Once the leak is located discharge and recover

the refrigerant in the system, repair the leak,

then repeat the evacuation procedure.

System

Vacuum

System

Vacuum

Temperature

In

Mercury

In Cm. of

Mercury

°C

28.0 71.0 38

28.9 73.4 27

29.4 74.6 16

29.7 75.4 5

29.8 75.7 -7

29.9 75.9 -18

Loading...

Loading...