SECTION 35 - HYDRAULIC SYSTEM 13

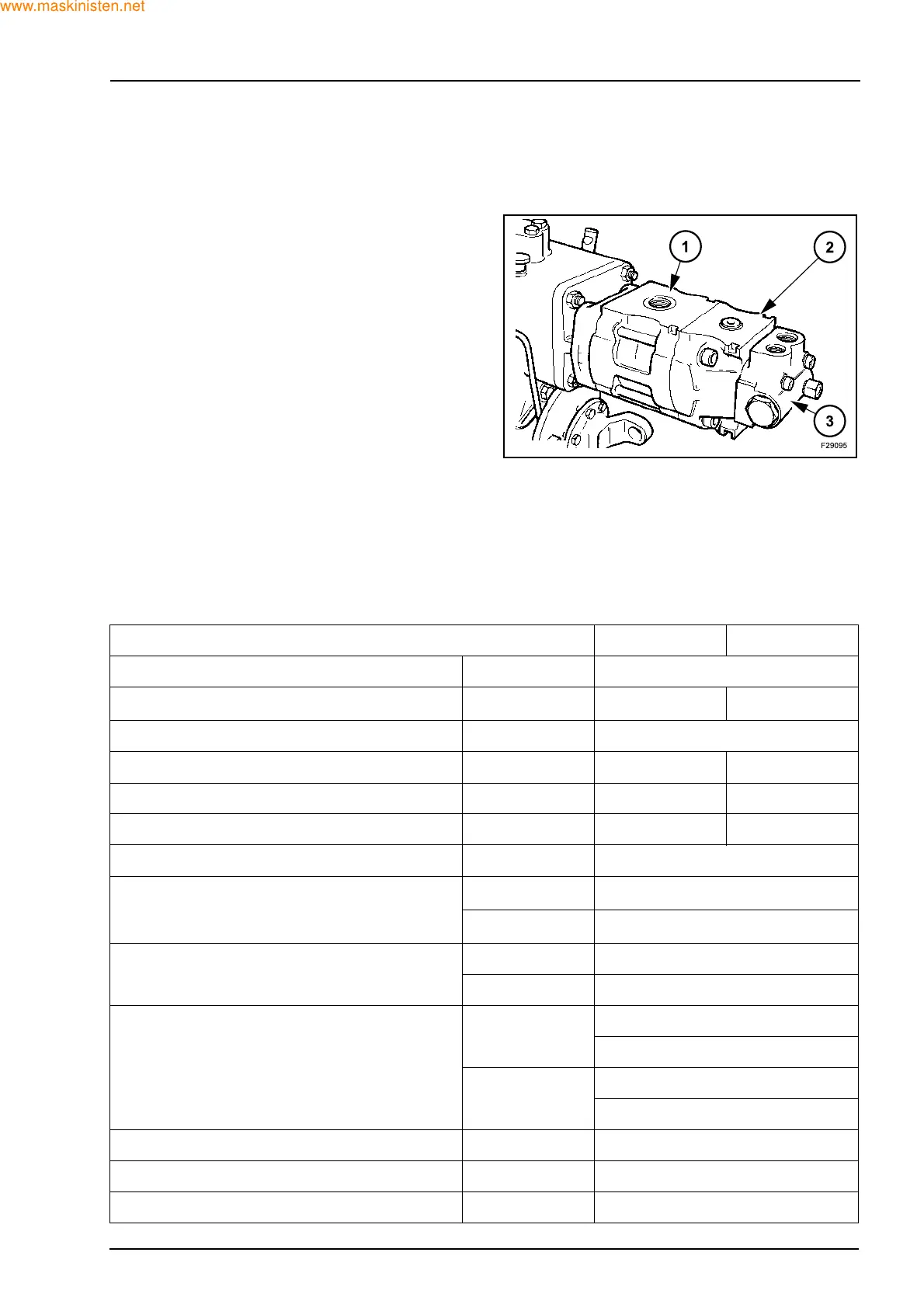

2. HYDRAULIC PUMP

2.1 DESCRIPTION AND OPERATION

There are two types of pumps:

Z for 97 HP engine;

Z for 110 HP engine.

The gear type hydraulic pump assembly is mounted

on the rear of the transmission and driven by a shaft

directly connected to the engine flywheel splined to

the torque converter housing.

The pump comprises of two pumping elements, the

front pump (1) rear pump (2) and load sensing steer-

ing flow divider control valve (3).

Oil is drawn through the common inlet port into both

pumping elements.

Front pump flow is directed to the loader and back-

hoe attachment control valves and to the sideshift

locking cylinders.

Rear pump flow passes through the flow divider

valve which maintains priority oil flow to the steering

system with remaining flow directed for operation of

stabilizers, loader and backhoe elements.

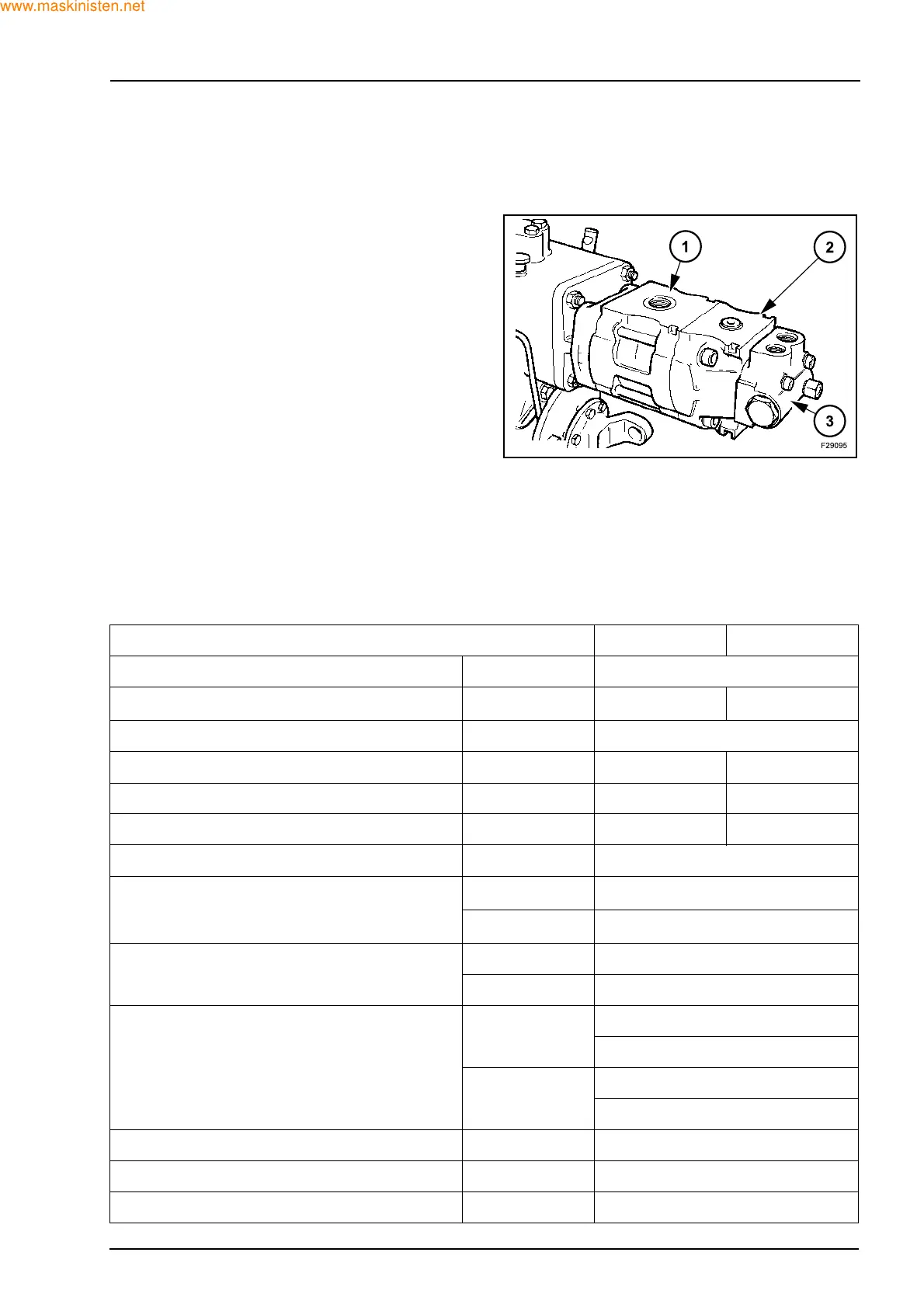

2.2 SPECIFICATIONS

PUMP (97 HP ENGINE) 1st PUMP 2nd PUMP

Direction of rotation (looking on drive shaft) Clockwise (D)

Displacement

40.258 (cm

3

/rev) 35.427 (cm

3

/rev)

Inlet pressure range for pump 0.7 - 3 bar

Maximum continuous pressure P 1 260 bar 260 bar

Maximum intermittent pressure P 2 280 bar 280 bar

Maximum peak pressure P 3 300 bar 300 bar

Operating temperature -25 to -80 (°C)

Speed

min P1

350 (min

-1

)

max P1

3000 (min

-1

)

Viscosity range

recommended 12 to 100 mm 2/s (cSt)

permitted max 750 mm 2/s (cSt)

Contamination class

Dp > 200 bar

bx = 75 - 10 mm

8 - Nas 1638

19 / 17 /14 - ISO 4406

Dp < 200 bar

bx = 75 - 25 mm

10 - Nas 1638

21 / 19 /16 - ISO 4406

Relief valve 177 ± 3 bar

Stand by pressure load sensing valve 7 bar

Weight 30 kg

Loading...

Loading...