4 SECTION 17 - TORQUE CONVERTERS

1.2 SPECIFICATIONS

Torque converter ratio............................................................................................................................... 2.38:1

Weight ..................................................................................................................................................... 17.4 kg

Torque of retaining screws for transmission .............................................................................................58 Nm

Torque of retaining screw for flywheel ......................................................................................................41 Nm

Torque of screw for drive plate to the convertor........................................................................................53 Nm

Torque of screw for drive plate to the flywheel..........................................................................................41 Nm

Hydraulic tests

Tachometer setting .............................................................................................................................. 2000 rpm

Test temperature, oil ............................................................................................................................. 80-85 °C

Cold start valve (for reference only) .......................................................................................................... 26 bar

System pressure test .....................................................................................................................13.7-15.2 bar

Torque converter....................................................................................................................................7-11 bar

1.3 OVERHAUL

The torque converter, is a welded unit and cannot be

disassembled. The only maintenance performed on

the converter, other than the stall test, is cleaning

and visual inspection. A commercial torque convert-

er cleaner may be used to clean the converter. How-

ever, if a commercial cleaner is not available, the

converter should be cleaned as outlined below.

Z Drain as much oil as possible from the hub of the

converter by tilting the converter in all directions.

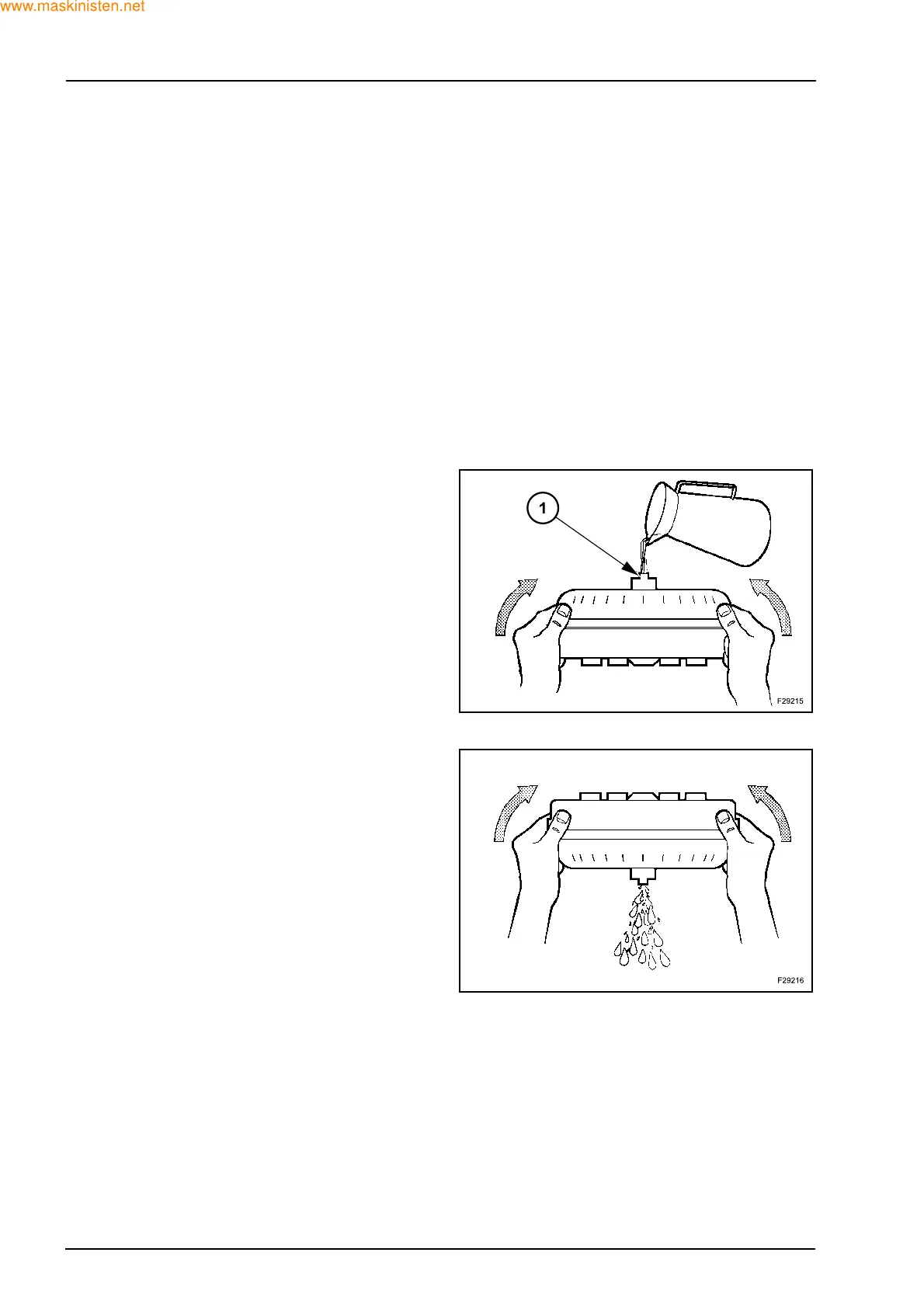

Z Fill the converter about half full, through the hub

(1), with paraffin base solvent or any cleaning sol-

vent specified for cleaning transmissions.

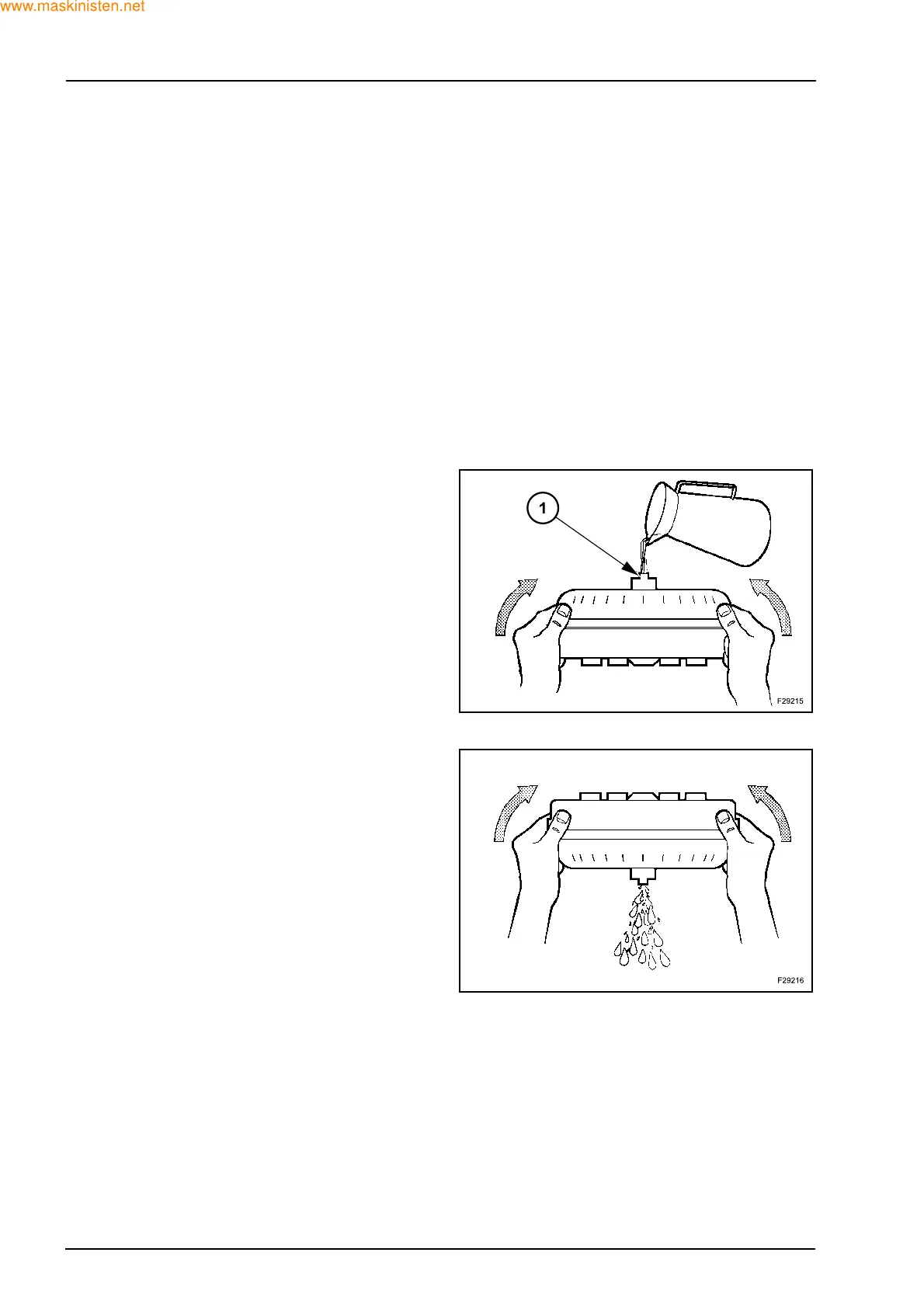

Z Plug the opening in the hub, then circulate the sol-

vent inside the converter by rotating and shaking.

Z Drain the solvent from the converter.

Z Repeat previous steps, as required, until the sol-

vent that is drained from the converter is clean.

1.4 INSPECTION

Inspect the splines on the converter hub for wear or

damage and the weld joints for cracks. If the hub is

worn or damaged and/or the weld joints cracked, a

new converter must be installed. A new drive plate

should also be installed if it is warped.

Loading...

Loading...