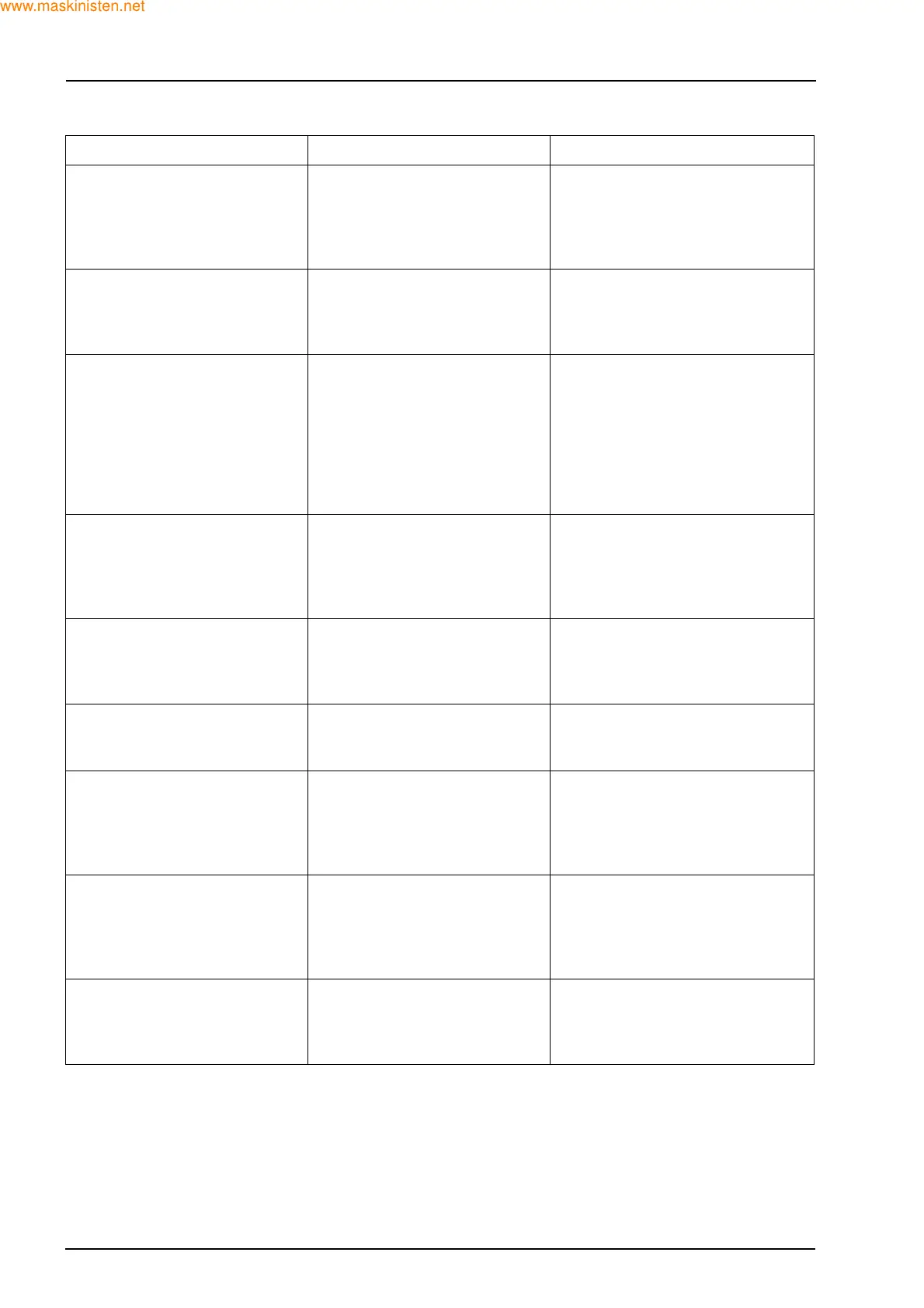

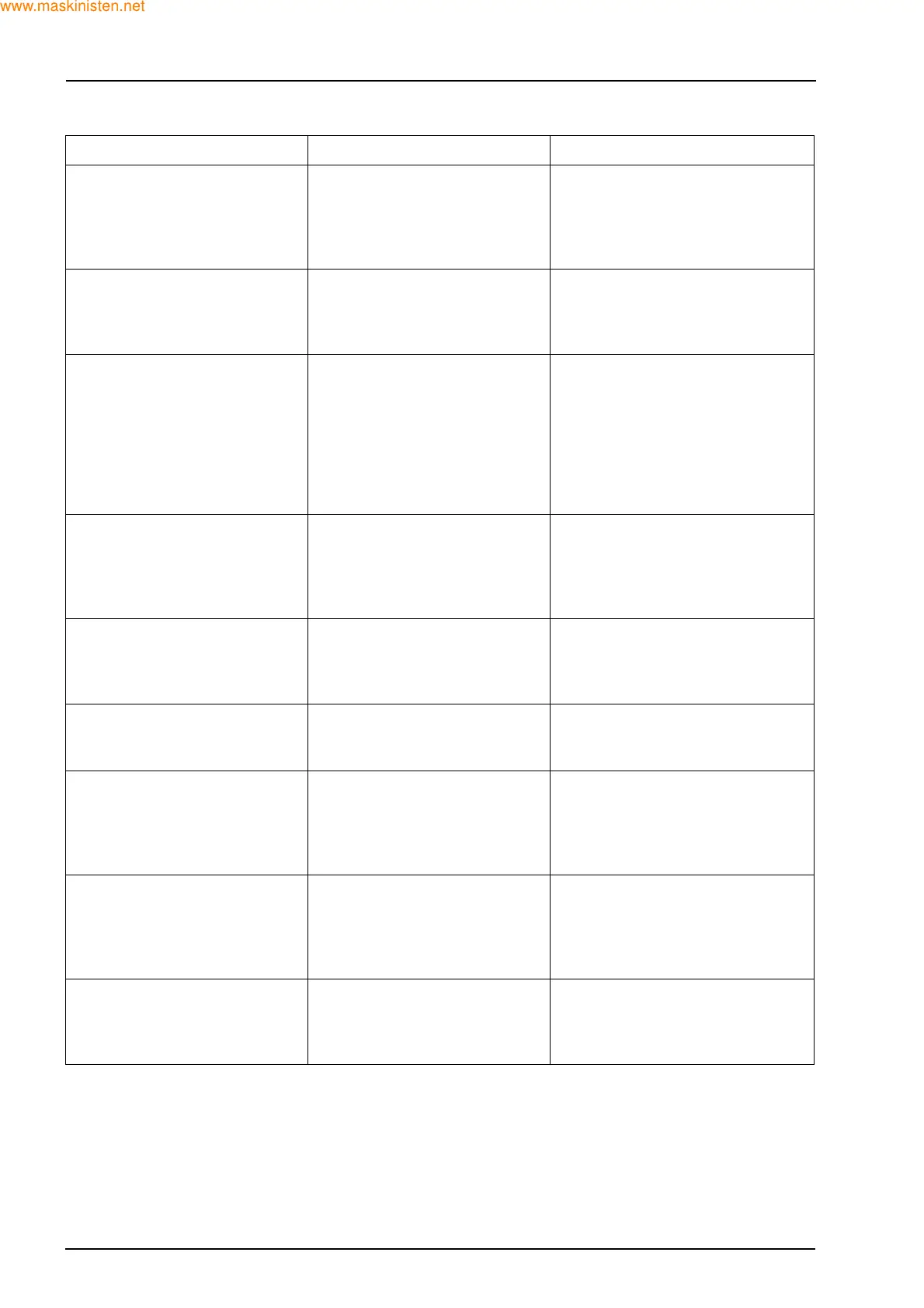

82 SECTION 27 - REAR AXLE

PROBLEM CAUSE CORRECTION

Ring gear tooth broken on the

outer side

Excessive gear load compared to

the one foreseen

Incorrect gear adjustment

(excessive backlash)

Pinion nut loose

Replace bevel gear set.

Follow carefully the recommended

operations for the adjustment of the

bevel gear set backlash.

Ring gear tooth broken side Load bump

Incorrect gear adjustment

(insufficient backlash)

Pinion nut loose

Replace bevel gear set.

Follow carefully the recommended

operations for the adjustment of the

bevel gear set backlash.

Pinion or ring gear teeth worn Insufficient lubrication

Contaminated oil

Incorrect lubrication or depleted

additives

Worn out pinion bearings that

cause an incorrect pinion axle

backlash and wrong contact

between pinion and ring

Replace bevel gear set.

Follow carefully the recommended

operations for the adjustment of the

bevel gear set backlash.

Use correct lubricants, fill up to the

right levels and replace according to

the recommended program.

Overheated ring and pinion teeth

See if gear teeth have faded

Prolonged functioning at high

temperatures

Incorrect lubrication

Low oil level

Contaminated oil

Replace bevel gear set.

Use proper lubrication, fill up to right

level and replace at recommended

program.

Pinion teeth pitting Excessive use

Insufficient lubrication

Replace bevel gear set.

Use correct lubrication, fill up to the

right level and substitute at

recommended intervals.

Axle beam body bent Vehicle overloaded

Vehicle’s accident

Load bump

Replace axle beam body.

Worn out or pitted bearings Insufficient lubrication

Contaminated oil

Excessive use

Normal wear out

Pinion nut loose

Replace bearings.

Use correct lubrication, fill up to the

right level and substitute at

recommended intervals.

Oil leakage form gaskets and

seals

Prolonged functioning at high

temperature of the oil

Oil gasket assembled incorrectly

Seal lip damaged

Contaminated oil

Replace the gasket or seal and

matching surface if damaged.

Use correct lubrication and replace

at recommended intervals.

Excessive wearing out of input

flange spline

Exhaustive use

Pinion nut loose

Pinion axle backlash

Replace the flange.

Check that the pinion spline is not

excessively worn out.

Replace bevel gear set if required.

Loading...

Loading...