SECTION 35 - HYDRAULIC SYSTEM 23

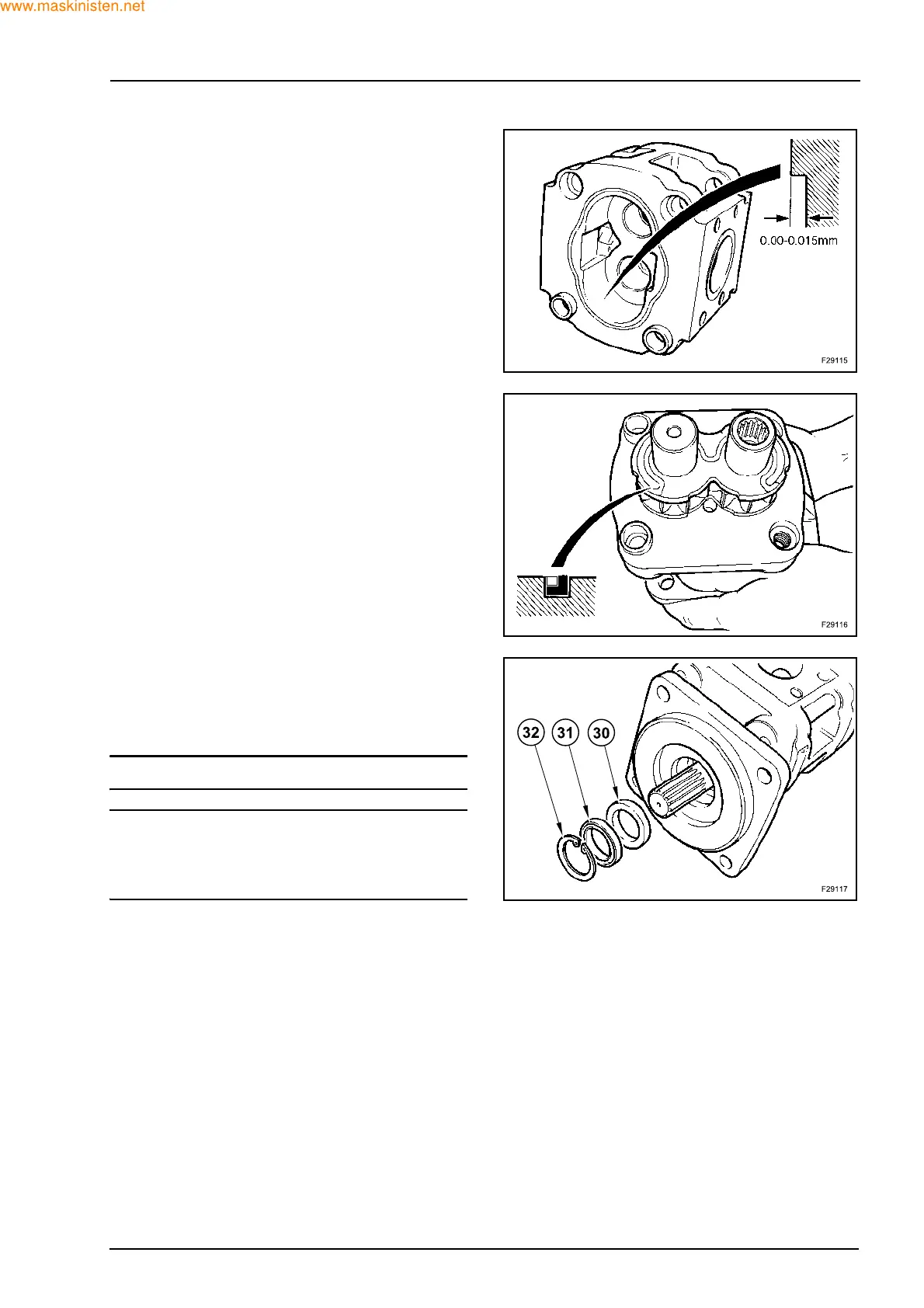

Inspect the wear track cut by the gears in the inlet

side of the pump body. The body can be reused if

the track is bright and polished and does not exceed

0.15 mm in depth.

Examine bearing block faces for scoring.

Inspect PTFE coated bearings in body or flange for

wear. If bearings are worn the bronze backing will be

revealed.

Examine pump gears for scored or worn side faces,

journals and damaged teeth.

Examine flange seal contact area on driveshaft. If

pump block, gears, bearing blocks or drive shaft are

worn the pump assembly must be replaced.

Reassembly follows the disassembly procedure in

reverse whilst observing the following:

Z Ensure all parts are perfectly clean and lubricate

bushes and gears with clean hydraulic fluid.

Z Replace all seals and O-rings.

Z Install bearing blocks into the same positions from

which they were removed.

Z Ensure back-up seals are correctly positioned in

the seal.

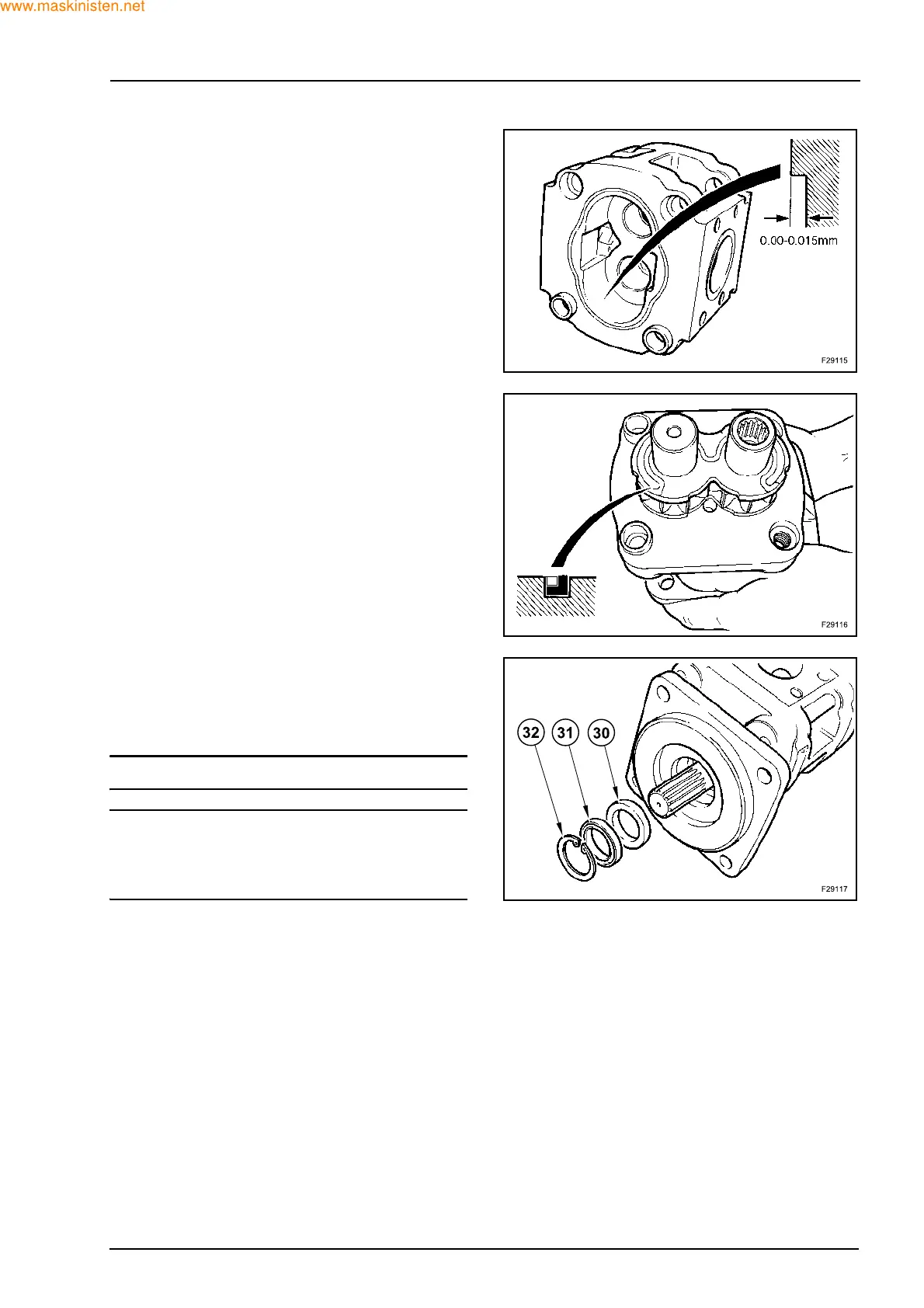

Assemble the inner seal, (30), with the spring and

the lip facing the pump. Install the outer seal (31),

with the spring and the lip facing outwards and refit

the snap ring (32).

Coat seal rings with high melting point grease.

NOTE: ensure seal rings are fitted back to back.

NOTE: if the seal ring recess has been scored dur-

ing seal removal, coat the outside diameter of the

seal ring with flexible gasket sealant to prevent leak-

age.

Loading...

Loading...