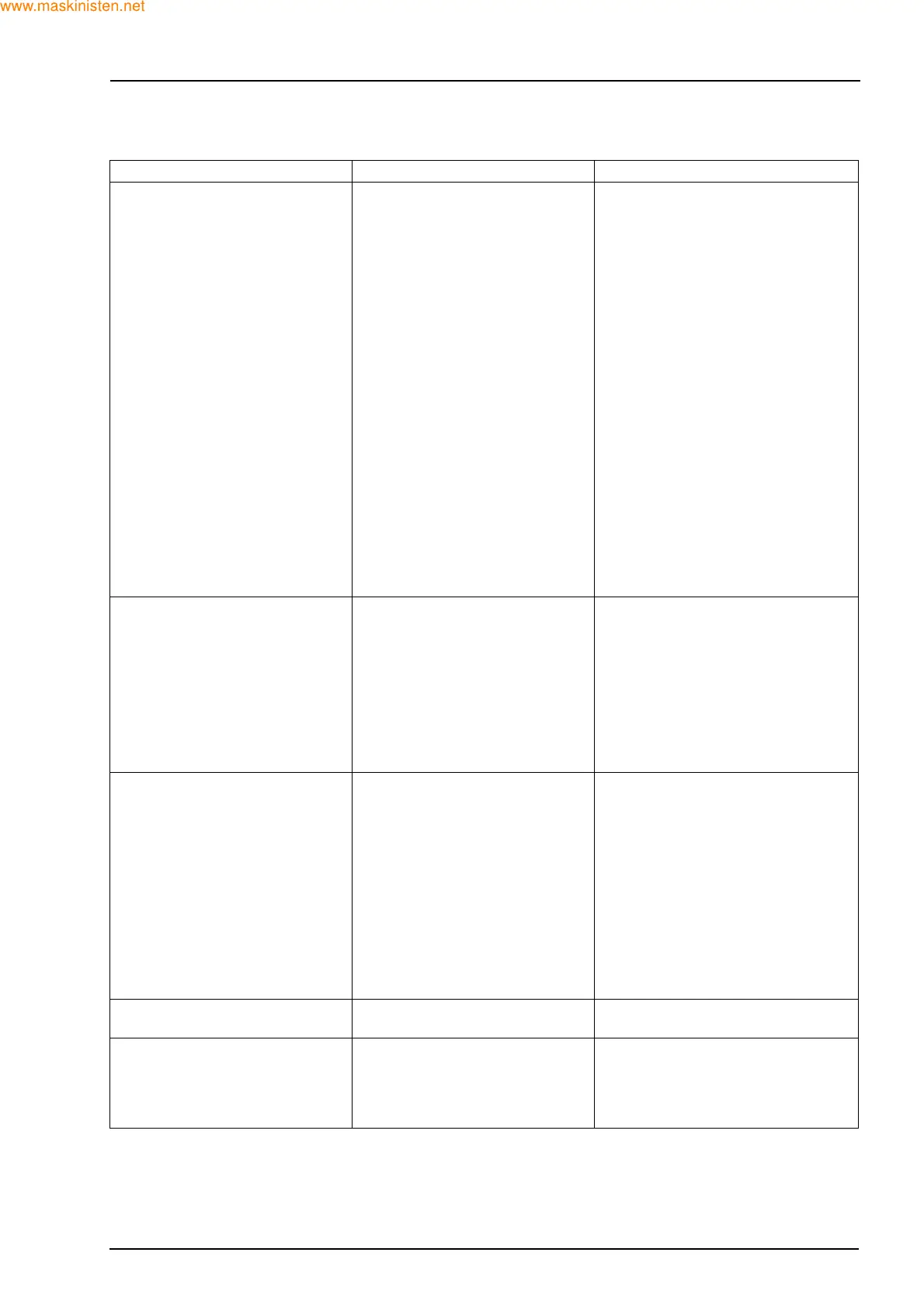

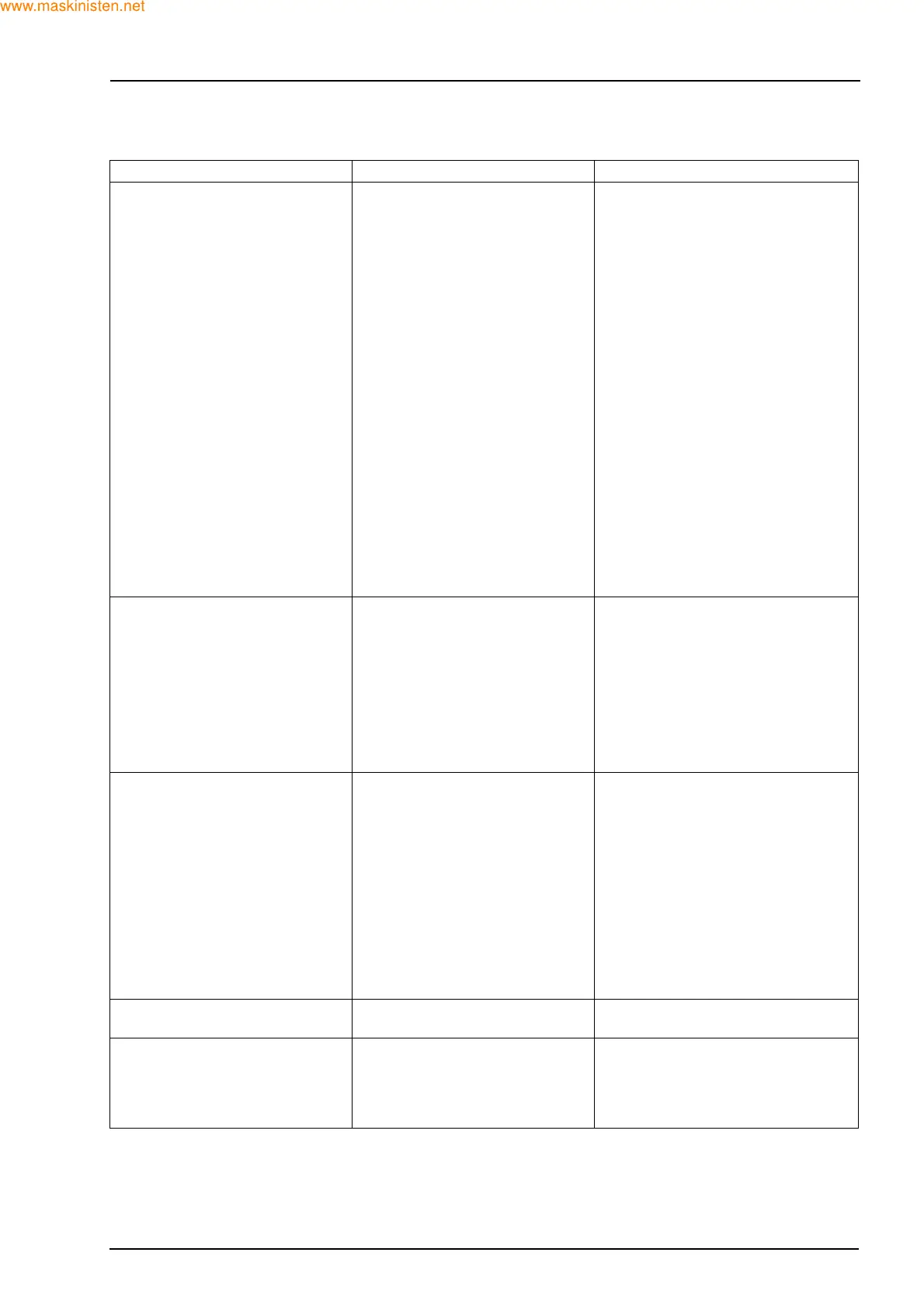

SECTION 35 - HYDRAULIC SYSTEM 123

HYDRAULIC PUMP

PROBLEM CAUSE CORRECTION

System noisy Worn or damaged pump gears or

pressure plates

Aeration: air entering the systems

at: suction tube, pump shaft,

fittings or cylinder ring nuts

Cavitation: restrictions in the

system at the suction line or at

the suction screen in the tank

Water in the system

The system relief valve vibrates

Vibrations in the lines

Cold hydraulic oil

Wrong type oil being used

Make a hydraulic pump performance

test.

Make a hydraulic pump performance

test.

Make a visual check and/or a

hydraulic pump performance test.

Visual check.

Check system relief valve, adjust/

overhaul as necessary.

Visual check.

Check the hydraulic oil operating

temperature.

Investigate/drain and top up.

Hydraulic oil drain through tank

breather

Tank overfilled

Aeration: air entering the system

at: suction tube, pump shaft,

fittings or cylinder ring nuts

Cavitation: Restriction of the

suction filter in the tank

Check the hydraulic oil level.

Make a hydraulic pump performance

test.

Make a visual check and/or a

hydraulic pump performance test.

Oil heating Oil supply low

Contaminated oil

Setting of relief valve too high or

too low

Oil in system too light

Oil cooler fins blocked

Fill the tank.

Drain the tank and refill with clean

oil.

Drain the tank and refill with clean

oil. Test relief valves.

Drain the tank and refill with oil with

the correct viscosity.

Clean the oil cooler.

Shaft seal oil leakage Worn shaft seal Replace shaft seal and inspect

pump.

Foaming oil Low oil level

Air in the suction system

Wrong oil type

Fill the tank.

Check/tighten suction line.

Drain and refill with correct oil.

Loading...

Loading...