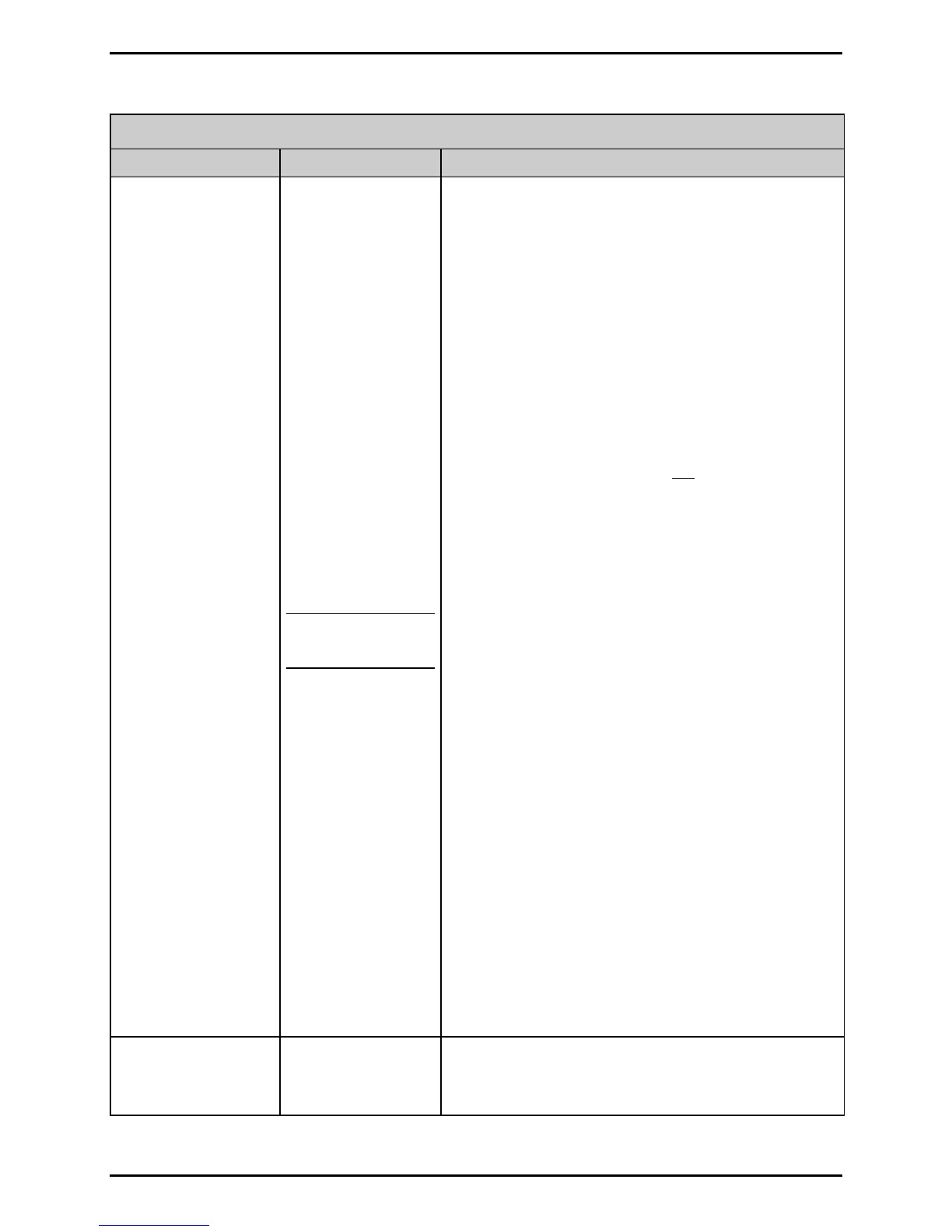

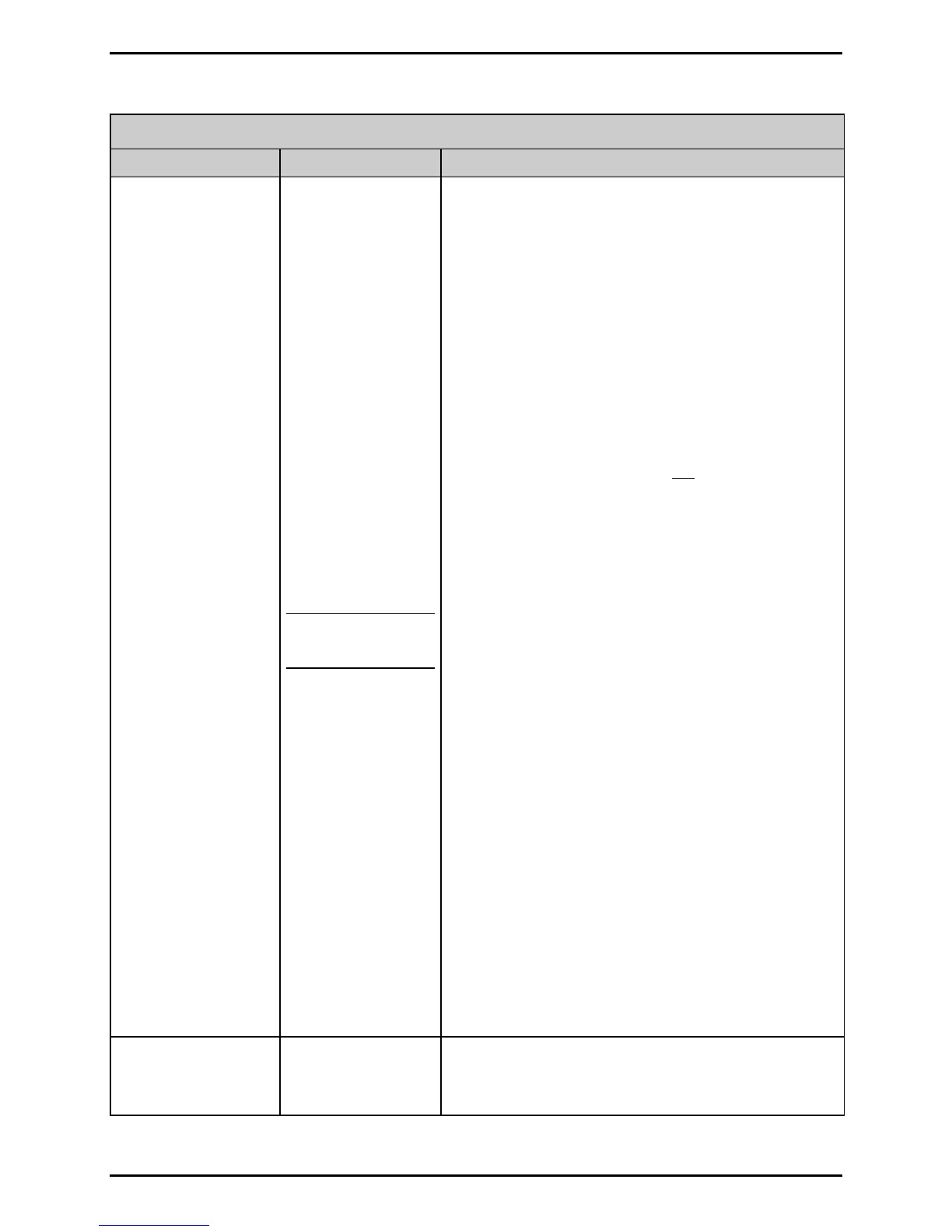

Troubleshooting

3-13

Fault Messages (continued)

Displayed Message Description Solution

SCANNER FAULT

A bar code could

not successfully be

decoded.

Note: This is

normal if a bar code

is not decodable.

Press FEED to clear the fault. Examine the failed bar

code and then if it is free of voids, with sufficient quiet

zones, try the following:

1) Ensure that the cabling from the scanner to the

Centerplate to the Backplane PCB is firmly

connected.

2) Cycle the power OFF and ON.

3) Check for debris on the scanner window and

clean it if necessary.

4) Ensure that the bar code is supported and is

within specification for the scanner.

5) Ensure that AUTO Mode is not being used if the

bar code is bitmapped or if addendums are used.

6) The settings may be too restrictive. Decrease

PRINT SPEED, increase the bar code height, or

adjust the MIN READABLE HEIGHT or the

REDUNDANCY LEVEL.

7) Align the scanner.

8) Ambient light maybe interfering with the optics.

Reduce bright light sources; alternately, increase

the lighting in low light conditions.

9) Ensure a level label and verify the scanner’s

alignment. The Tear Bar or Rewind Plate should

be installed; or, if using an external rewinder,

attached to that device.

10) If using same data multiple-up bar codes, ensure

that sufficient white space exists between the

rows.

11) Possible missing jumpers on the Backplane PCB,

E1-E2 & E5-E6 should be installed.

12) Possible defective scan head; replace it.

13) Possible defective Backplane PCB; replace it (see

Section 4.12).

14) Possible defective Main Logic PCB; replace it (see

Section 4.11).

STROBE TIMING

FAULT

A printhead clocking

problem has been

detected.

Attempt to clear the fault by cycling the power OFF

and ON; if the fault does not clear, replace the Main

Logic PCB (see Section 4.11).

Loading...

Loading...