DS-320SA

Instruction Manual - 24 -

www.doallsaws.com

Attention: Make sure that there is enough space for operators, repair, maintenance and material

manipulation space when installing the machine.

For additional information, refer to Heading 5.6., Safety Regulations.

8.3.2 ACHORING INSTRUCTIONS:

- Check the foundation to ensure it meets the requirements outlined in Heading 8.2.1, Foundation

Requirements.

- Using the proper lifting equipment (forklift, hoist, machine skates), set the machine in place.

- Place a digital machine level (or equivalent) on the machine (on a flat surface).

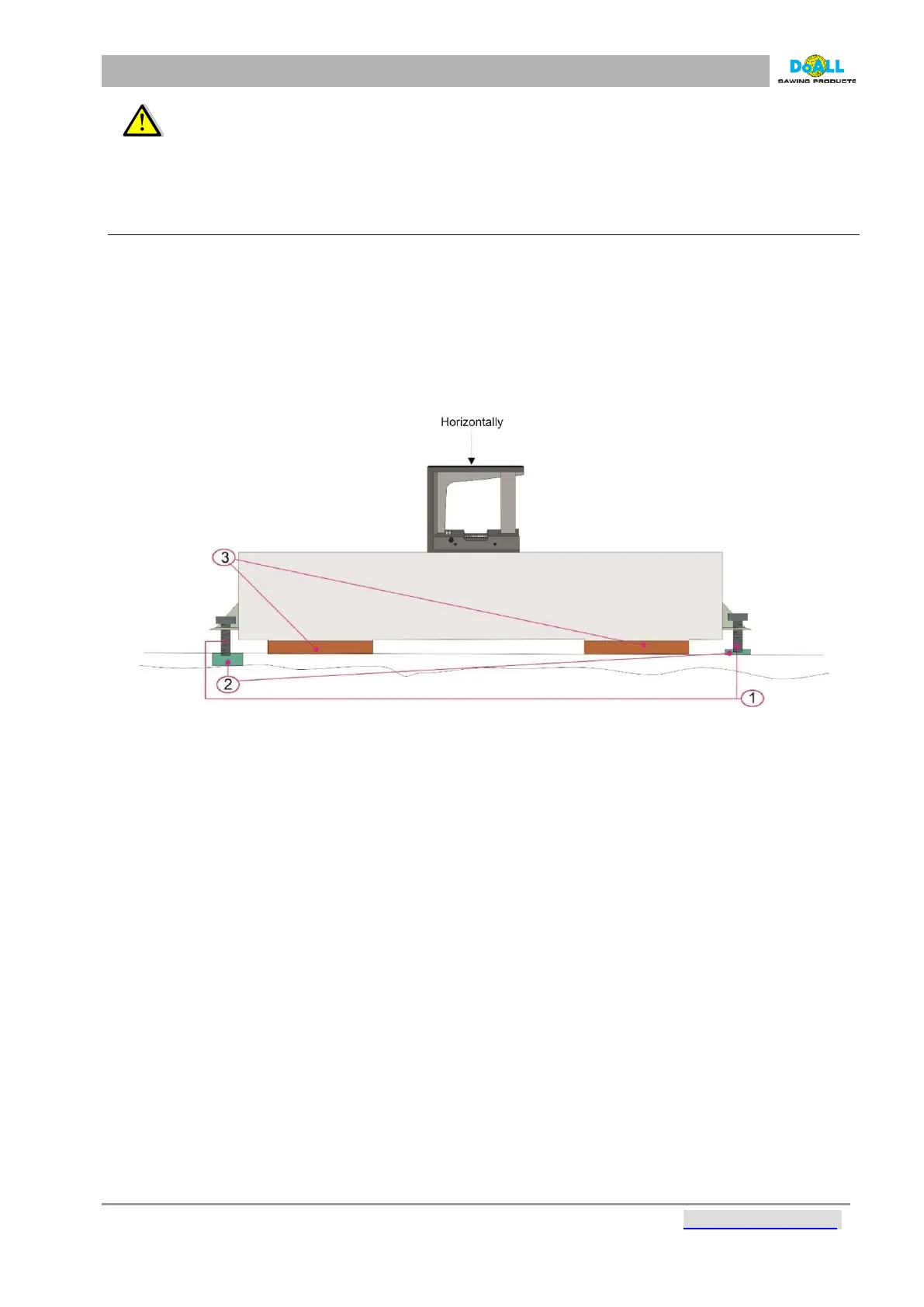

- using leveling screws (1) level the machine directly to plane. We recommend to put sheets of metal

with minimum 0,4 inches thickess under the stand screws. Check the plane with the scale on the

table. Machine has to be leveled in both longitudinal and diagonal directions.

- After the accurate machine setting support the base of saw with sheets of metal close the standing

screws with appropriate height (3). Dimensions of the sheets should be at least 4x4 inches..

pic: 8-1

- Drill the holes for anchors and then anchor the machine (4). Stand screws must be loosened before

tightening the anchors, so the machine is not standing on the screws when tightening. The machine

base cannot be deformed. Use anchors with mechanical wedge M12 (1/2”), recommended anchor

length is 8 inches, or anchors with chemical addition M12 (1/2”), recommended anchor length is 8

inches.

- When the machine is set in place, you can dismantle the fixation parts for machine transport.

Loading...

Loading...