DS-320SA

Instruction Manual - 49 -

www.doallsaws.com

12. HOW TO CHOOSE THE RIGHT SAW-BLADE

There is a connection between the right choice of saw-blade and an ideal output of machine.

DoALL company also deals with a production and selling of saw-blades for metals.

Warning : In case of wrong choice of teeth shape and size regarding the material to be cut, pulley,

bearings, gear box and engine could be overloaded and enormously worn away. When using small teeth

regarding the length of the cut a long chip appears, this too long chip is too big for the gap between teeth,

and tries to enlarge into sides.This fact – overfilling of the teeth gap – causes gradual wedging of the chip in

the cut, the loss of quality of the cut and enormous increase of the cutting resistance and input of the

machine. The claim of damage of pulley, bearings, gear box and engine from above mentioned reasons

would not be considered as a warranty claim.

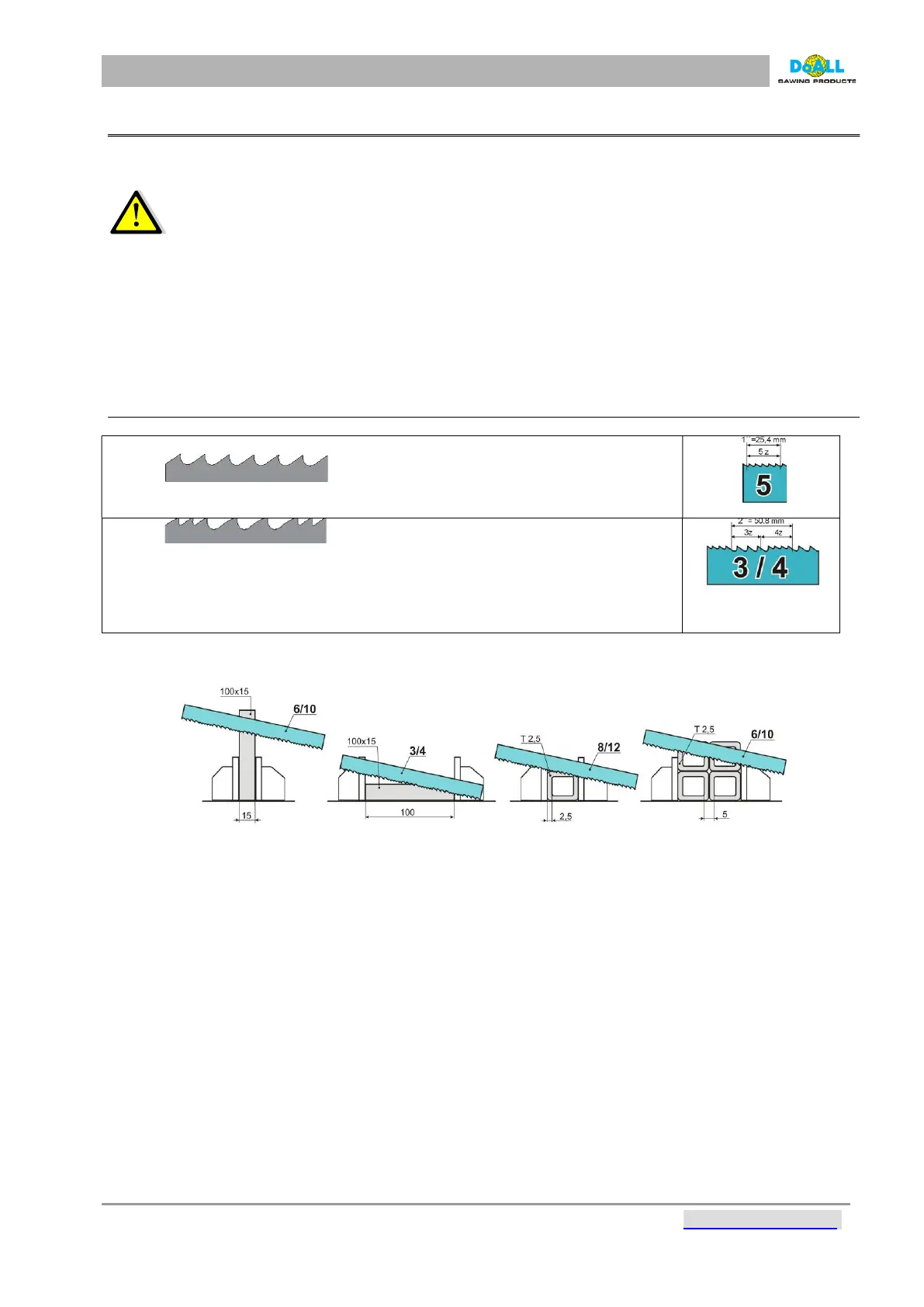

12.1 SAW-BLADE TEETH

CONSTANT - distance between teeth is constant

VARIABLE - smaller and bigger teeth are changing. This saw-blade has a

bigger rate of using, it loweres vibrations during cutting, it enables better removing

of chips, it causes a better surface of a cut. Life cycle of the saw-blade is bigger. -

technicians are ready to help you with the right choice of saw-blade.

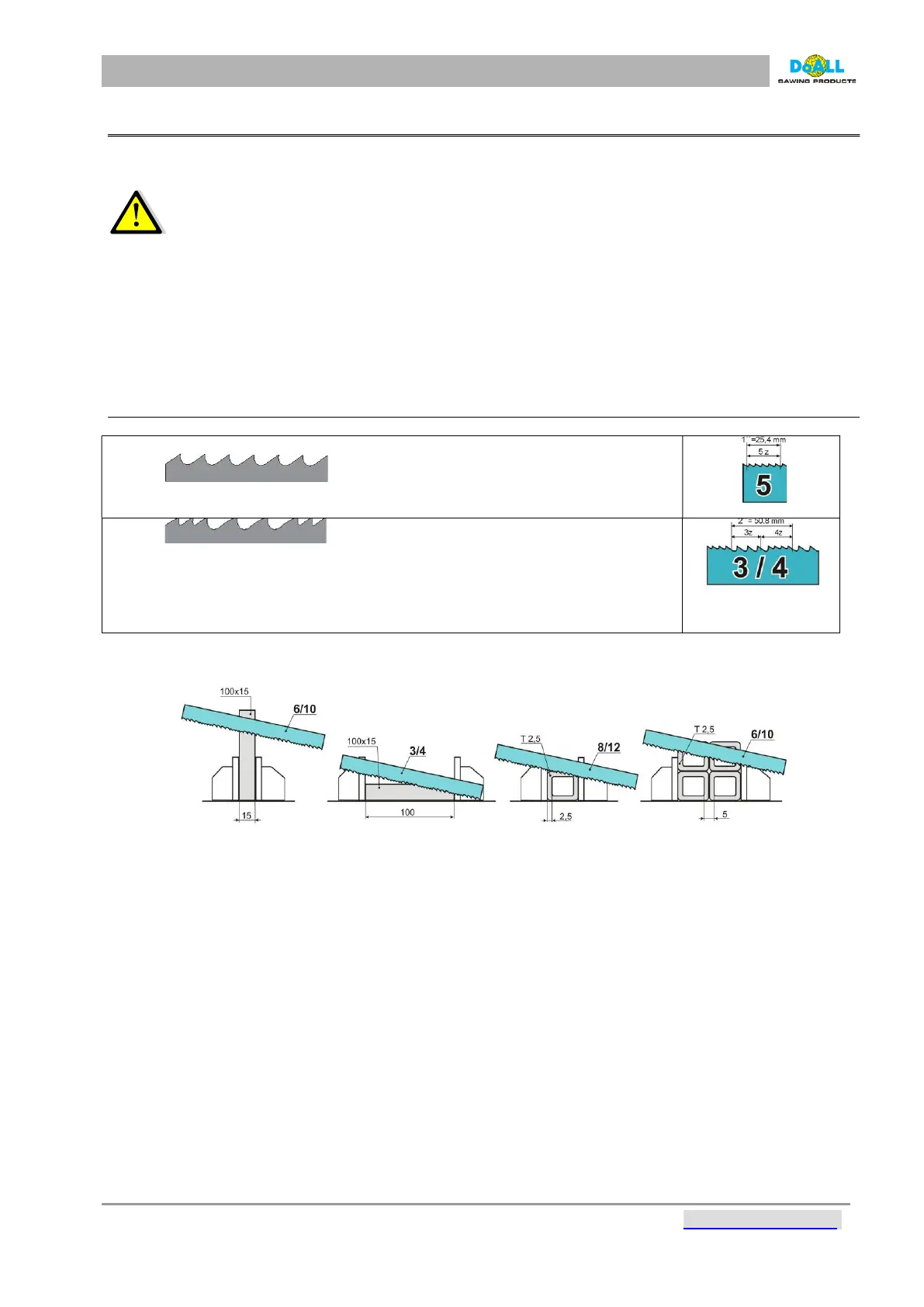

How to choose the right teeth for cutting solid material

tab: 12-1

WARNING:The position of the material in jaws influences the right choice of saw-blades teeth

pic 12-1

Loading...

Loading...