DS-320SA

Instruction Manual - 66 -

www.doallsaws.com

14. SERVICE INSTRUCTIONS

For service assistance, we recommend using only DoALL factory-authorized service technicians.

If the machine is under warranty, the customer is not allowed to perform the procedures in this section.

Before you embark on the below-mentioned procedures on your own, you must be sure that you can

manage the task. The DoALL company does not vouch for the accuracy of the text or your potential failure.

14.1 ADJUSTMENT OF BAND GUIDES

The band guides are factory-adjusted. The operator must not tamper with or modify the current setting of the

band guides.

We suggest inspecting it once a year, together with inspection of the band tension.

It is not necessary to adjust the guides if the operator does not hit them etc.

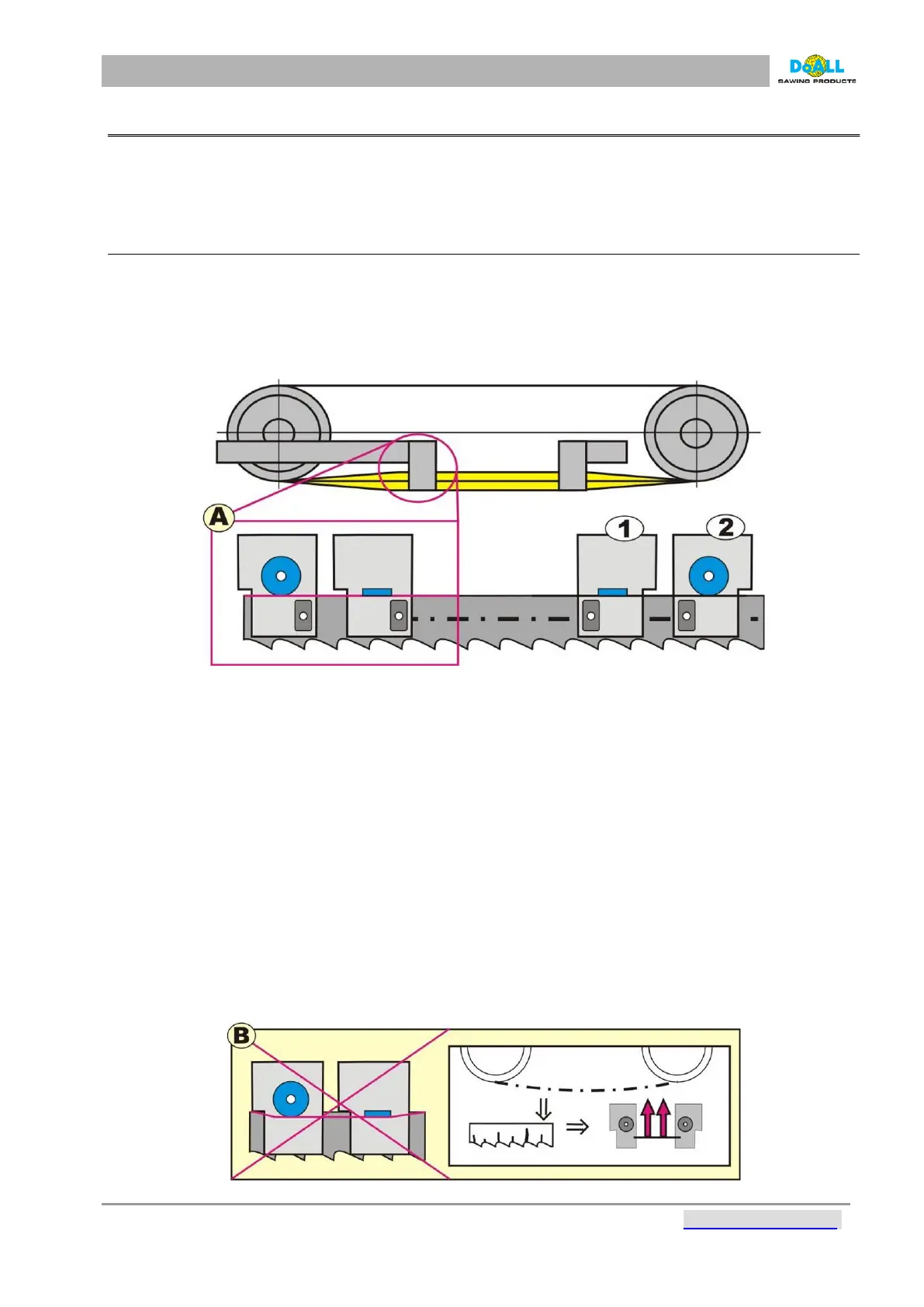

For optimum band life and cutting accuracy it is necessary to ensure that the band moves naturally in the

guides and is not moved anywhere by the guides or the material – refer to Pos. 1 in the picture.

pic 14-1

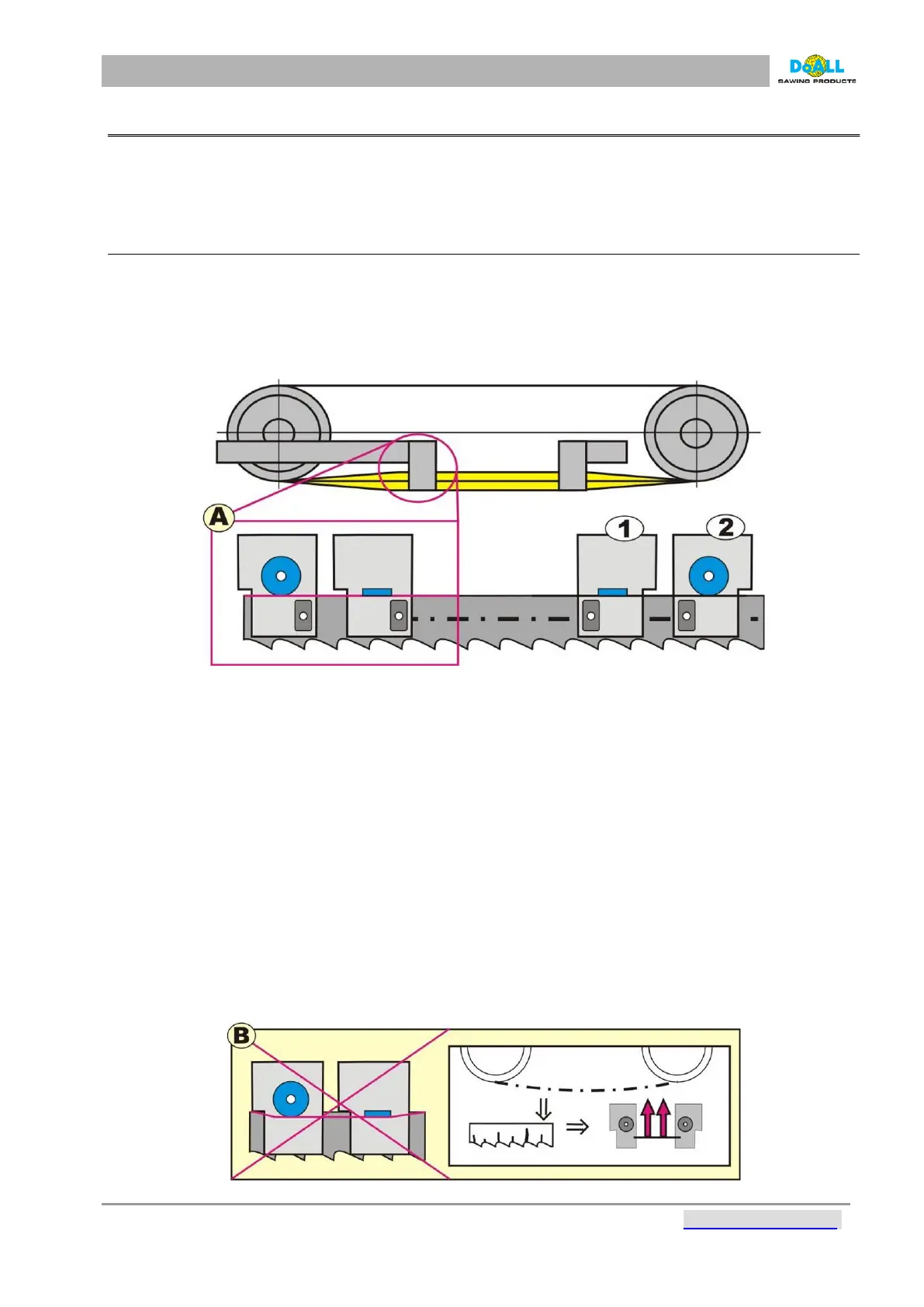

If the band is dragged downwards by the guides (Pos.B) or upwards by the sawn material (Pos. C), it means

that it is not correctly guided and the guides should be adjusted.

The position of the guides can be adjusted by moving both guides up (approximately 2 mm). This will create

a clearance between the guide pad (roller) and the band.

Replace all guards and start the saw band. Stop the machine after approximately 10 seconds. Now the band

has reached its ideal position.

Important: turn off the main switch and disconnect from the mains.

Use a wooden block to push the saw teeth from the bottom in the location of the guide. Use a slide gauge to

measure the distance by which the band moves up. The guide should be lowered by this value.

Use this method for the second guide.

If you decide to adjust the guide on your own, clean it from the inside (assist yourself by removing a spacer,

which is not adjustable) and always check the condition of the carbide guiding areas.

It often happens that the customer requires a guide adjustment without noticing that the saw band has made

a groove in the upper part of the pad (or roller) – see Fig. D. In this case it is enough to replace the pad (or

roller) and keep the position without change.

Loading...

Loading...