DS-320SA

Instruction Manual - 63 -

www.doallsaws.com

13.2 RECOMMENDED FILLINGS- INTERVALS FOR CHANGING FILLINGS

It is very important to change the oil in components at the prescribed intervals to ensure efficient

machine operation. If the oil changes are not completed in accordance to the recommended

intervals, the manufacture reserves the right to reject all warranty claims submitted for any part of

the hydraulic system.

Every change of oil must be written down in the Service book by the authorized service of DoALL. In case of

missing notice about regular change of oil the warranty will not be considered. Your Service book must be

always kept near the machine. It is an obligation of the byuer to present the Service book to the service

technician of DoALL company and check the completeness and correctness of the notice.

The change of oil must be provable.

Specification Recommended

Alternatives Oil Change

A Hydraulic oil ISO-L-HM 32 ESSO:

OMV:

hours

gear oil ISO-S150

C Emulsion oil ISO-L-HFAE ESSO:

BS TOP CUT 97-52

OMV:

UNIMET ASF

192

Every 6 months

D Oil for MINI-

LUBE::

multifunctional oil

based on

synthetic ester

Oemetea:

HYCUT SE 12

- when needed –see

you tab 15-1

E Plastic lubricant DIN 51502

KP 2 P 20

Q8 RUYSDAEL OMV:

SIGNUM M 283

F Universal

lubricating oil

WD 40 MOTIP: MPL20

MULTI SPRAY

when needed

tab: 13-2

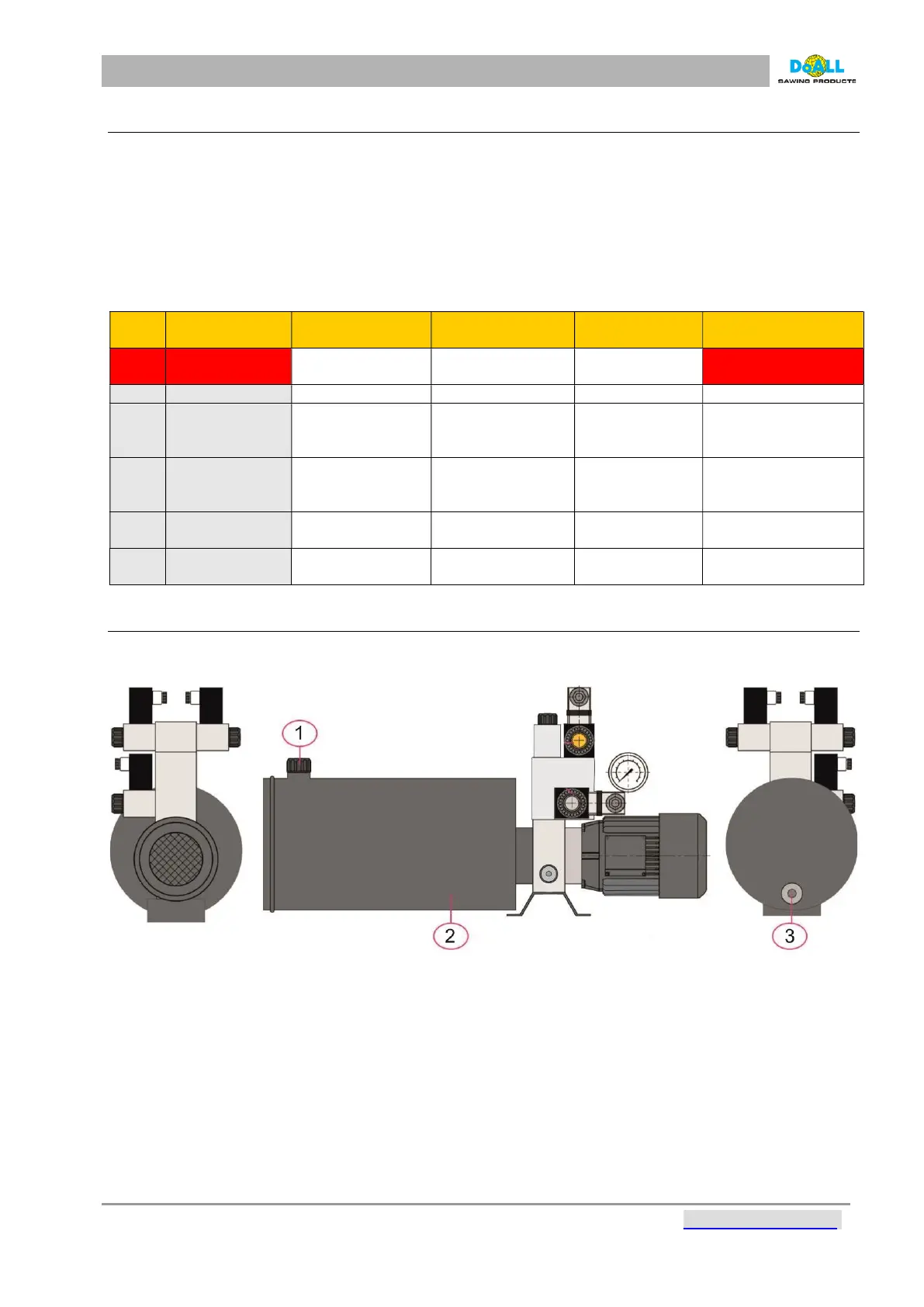

13.3 CHANGE OF HYDRAULIC OIL

The oil level is measured using the gauge located under the lid (pos.1). Unscrew the lid and check the oil

level on the dipstick. The level must be between the two marks.

pic: 13-2

1. Fill plug - under the lid is an oil gauge

2. Tank for hydraulic oil ISO VG 32

3. Drain plug

Loading...

Loading...