DS-320SA

Instruction Manual - 64 -

www.doallsaws.com

13.4 FILLING THE TANK WITH OIL

Check the inner part of the tank very properly first. Check the condition of oil resistant paint. If you find any

flaking or marks of bad quality, the best thing is to remove the damaged paint by a suitable solvent, wash it,

dry it and clean by pressured air. It is a prevention of damages caused by bad painting that could pollute all

hydraulic system. For filling use only oil recommended by the producer. Never pour the oil directly from the

barrels, always use filter aggregate with filters finer than 25 μm. The best is to use two filters with different

filter ability. The first one with the rough metal filling, the second one fine with paper filling. Use filters that

signal pollution, you will improve and lighten your work. There is the red cover of the oil filter that serves as

the plug for pouring the oil.

If you change the hydraulic oil, you usually dismantle also the cover of the tank. We recommend to check the

state of the clutch between the pump and electroengine. It is necessary to grease surface of the clutch by

the plastic lubricant- transfer of twisting moment ( see service instructions).

Recycle used oil. Contact a recycling facility to have the oil recycled properly to protect the

environment. Do not dump the oil on land or dispose of it in waterways.

13.5 FILLING AND CHANGING PUMP COOLANT

use only liquids delivered by DoALL – and mix them in recommended proportions. Pay attention to

right placement of the tank for chips and liquid tank.

When operating with coolant, wear impermeable protecting gloves and protective glasses. If the

liquid got into the eyes, the eyes could be injured.

When stirring the coolant, pour the concentrate into the water and stir continuously. All information

needed are mentioned directly on the vessel or in covering documents.

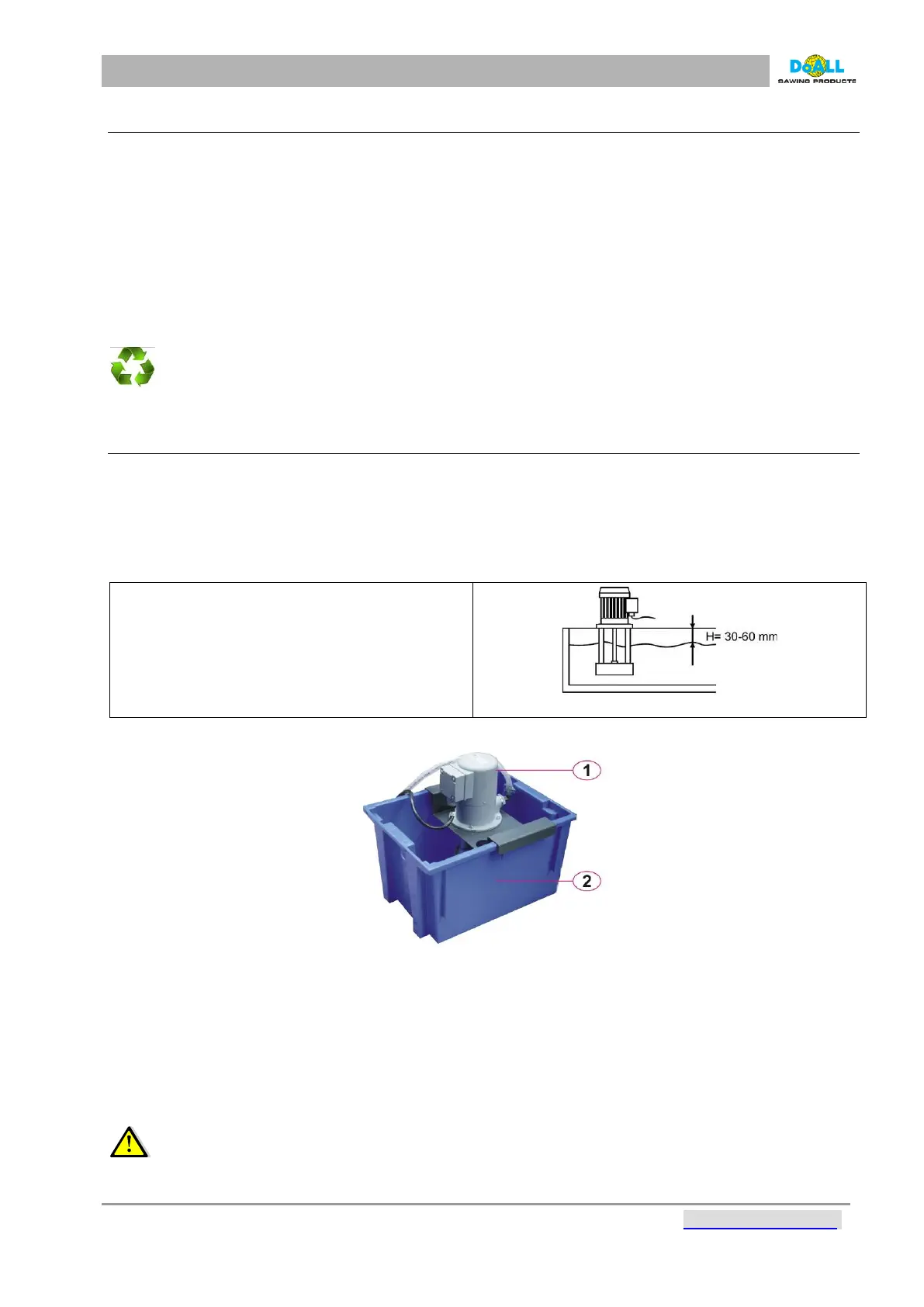

It is the operator's responsibility to check the

amount of coolant in the reservoir. The

coolant level is from 1,2 to 2,4in below the

level of the flange of coolant pump.

pic: 13-3

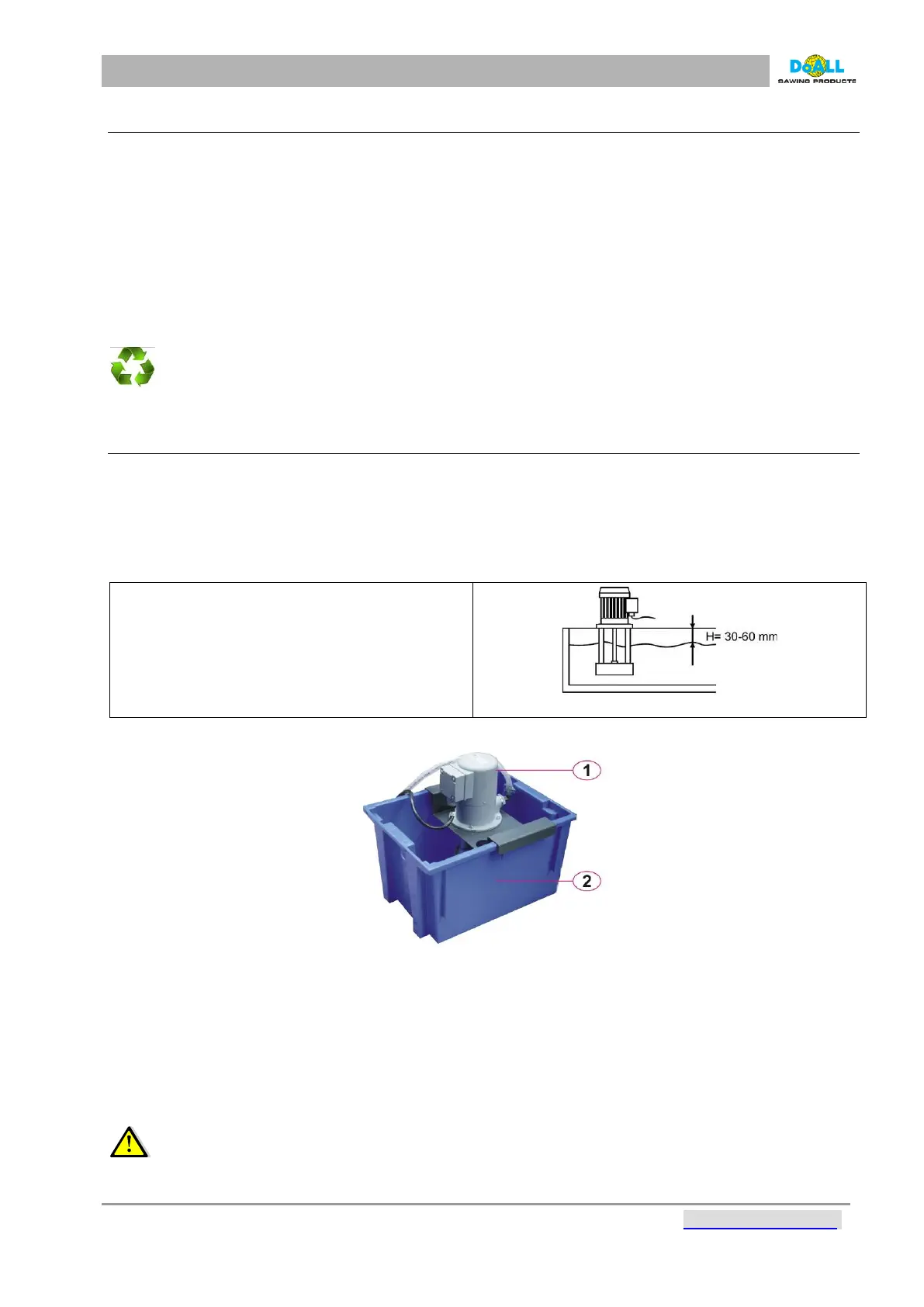

pic: 13-4

Procedure for replacing coolant:

1. Pump out the coolant from tank by pump and hose (or coolant pistol).

2. Remove the pump with holder from tank (pos. 1)

3. Clean the tank (pos. 2) and the pump

4. Fill up the tank with new coolant

5. Put back on it the holder with pump

6. Connect the coolant drain hose to coolant tank

Warning: the exchange tank coolant is necessary to use a tank with an overflow hole, otherwise it may

lead to flooding of the pump coolant. For this damaged pumps will not be recognized claims.

Loading...

Loading...