DS-320SA

Instruction Manual - 26 -

www.doallsaws.com

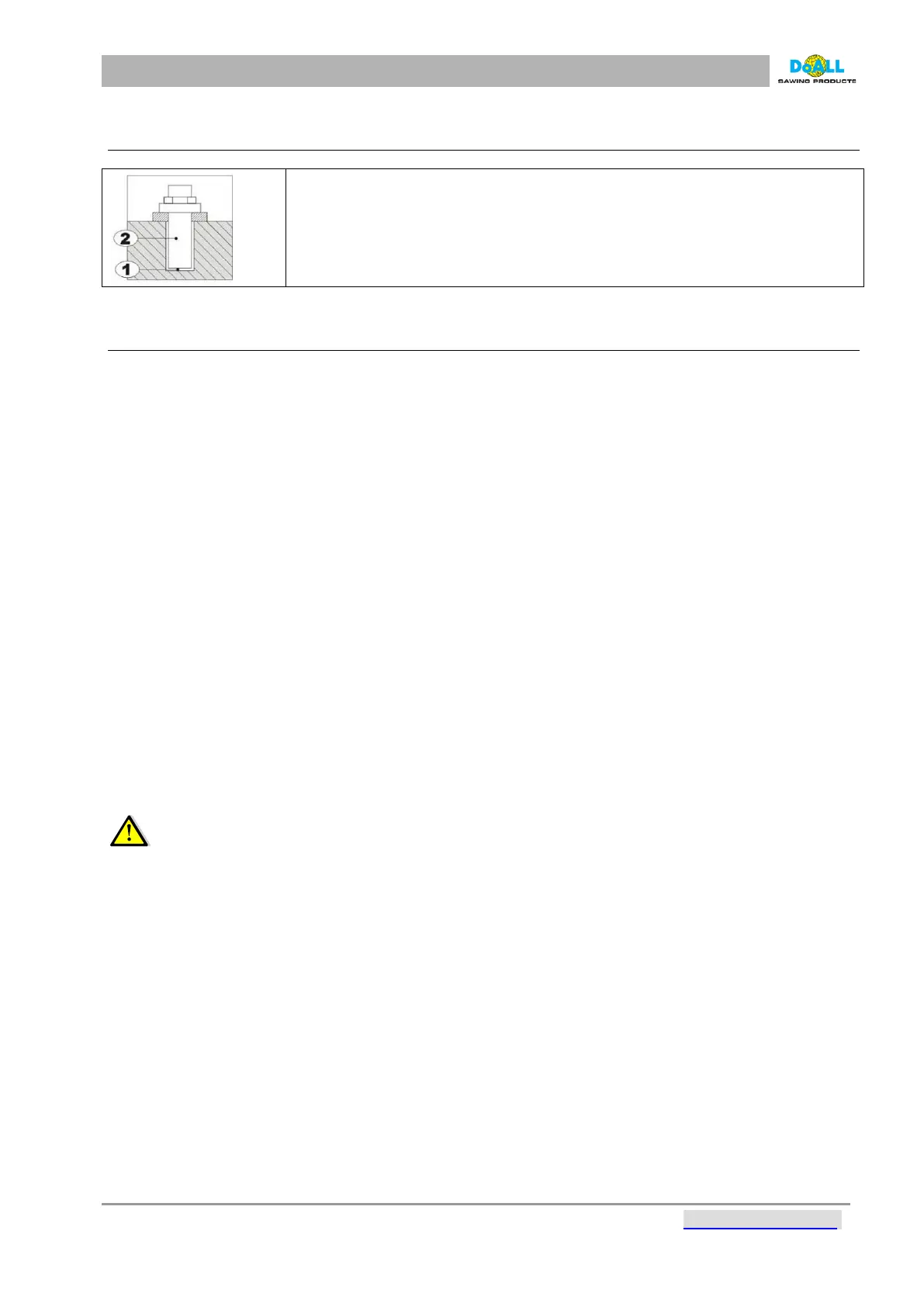

8.5 HOW TO ANCHOR MACHINE TO THE FLOOR

1. Drilled hole in floor D=0,5in, depth 9in

2. Anchor M12 (1/2”), length 8in

If the mechanical anchor cannot be used, then the threaded rod M12 (1/2“) can

be used, to depth 9in, drill hole D=0,6in, use chemical glue and fix the threaded

rod with the glue.

8.6 CONNECTING TO THE ELECTRICAL NET

Any work on electrical equipment of the machine may be performed only by persons with the

corresponding qualifications according to the valid regulations and standards.

The electrical equipment of the machine should be connected to the three-phase 3PE AC 230V 60Hz, TN-C

(or 2 AC 24V 60Hz, TN-C) (see technical data in the electronic documentation.) power network, by means of

a flexible lead with one end firmly attached to the main connectors of the machine and the loose end for fixed

connection to the object’s electrical power network. Recommended types of power supply protection are

listed in a manual, part electronic documentation. The plug is not supplied.

The correct connection of phases can be checked on the pressure gauge of the hydraulic central unit – it

should equal 300 PSI.

Marking of cables and connectors:

Connecters L1, L2, L3 – outer (phase) marked red, black, blue.

Connecter PE – guard wire, grounded base marked green.

The socket circuit for connection of the machine (or the circuit for the power network where the saw will be

connected) must be carried out according to the valid regulations and technical standards, which relate to the

particular equipment.

Protection against electric shock refers to the requirements of the valid regulations and technical standards

for automatic disconnection from the power supply.

We recommend connecting the machine to a circuit equipped with a 30 mA residual current device, which will

enhance basic protection against electric shock.

The design and use of guard wires must conform to the respective requirements.

ATTENTION: Only authorized personnel or a licensed electrician is allowed to make electrical

connections on this machine. The authorized person must be fully acquainted with the equipment and after

connection is obliged to inspect the correct operation of the electrical equipment including protection and

safety disconnection and blockage.

It is recommended to make a routine control of all connections, adjustments and bolts in electronic

case before first connection of it to electrical network.

If it is proven that the machine receives ELECTRIC SHOCK CAUSED BY HIGH INDUCTION ELECTRIC

NETWORKS, the warranty conditions have not been complied with and the machine supplier is

entitled to send invoices to the machine operator for all replaced and destroyed machine parts that

the operator claims or has claimed.

Loading...

Loading...