Base

Engine Components

DODGE

Turbo Diesei

Alternative Repair Procedures

Page9K-17

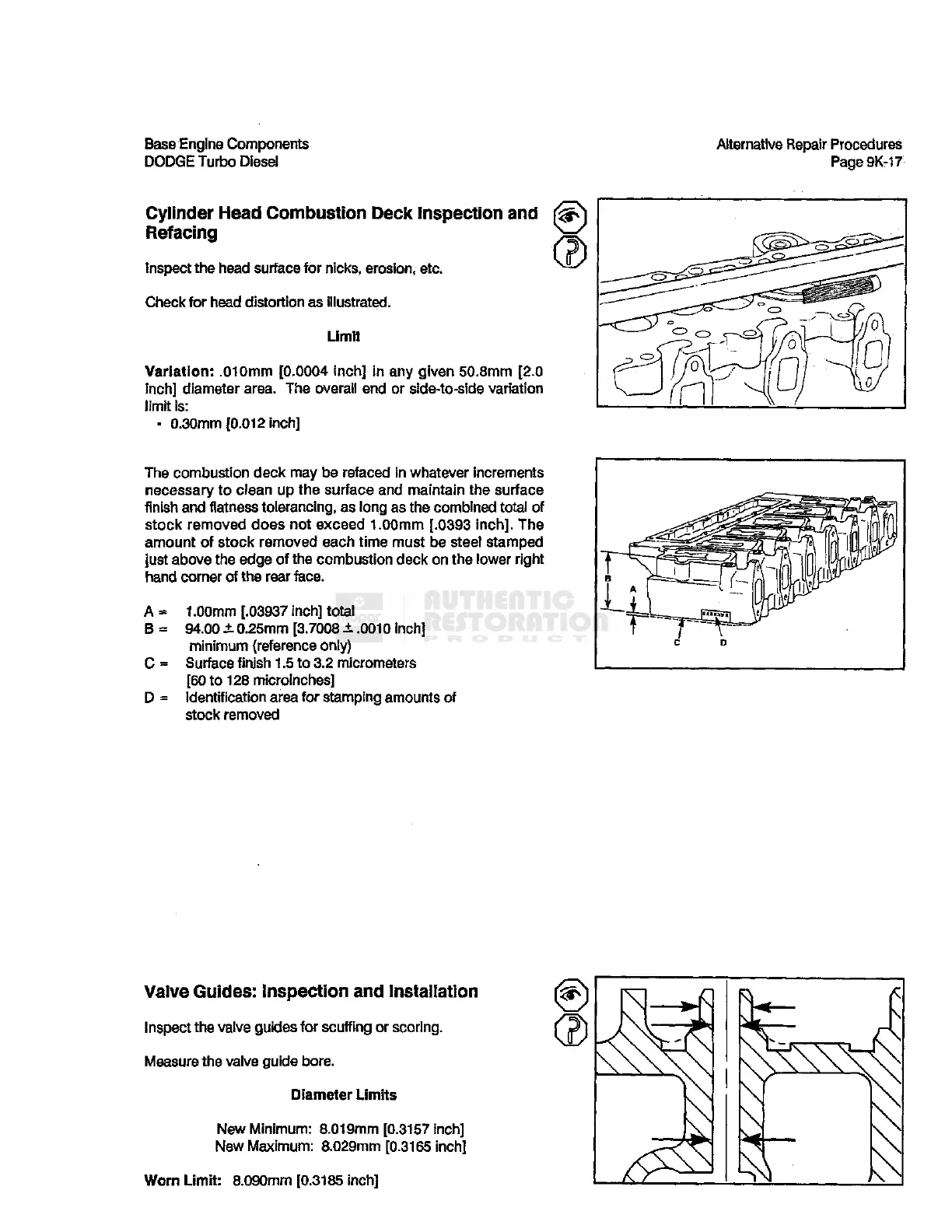

Cylinder Head Combustion Deck Inspection and j^fo

Refacing S=*^

Inspect the head

surface

for

nicks,

erosion, etc.

Check

for head distortion as illustrated.

Limit

Variation:

.010mm

[0.0004

inch] in any given

50.8mm

[2.0

inch]

diameter area. The overall end or side-to-slde variation

limit

is:

•

0.30mm

[0.012

inch]

The combustion deck may be refaced in whatever increments

necessary

to clean up the surface and maintain the surface

finish and

flatness

tolerancing, as long as the combined

total

of

stock

removed does not exceed

1.00mm

[.0393

inch]. The

amount of stock removed each

time

must be steel stamped

just

above the edge of the combustion deck on the lower

right

hand corner of the rear face.

A

«

1.00mm

[.03937

inch]

total

B

=

94.00

±

0.25mm

[3.7008

± .0010 inch]

minimum (reference only)

C

« Surface finish 1.5 to 3.2 micrometers

[60 to 128 microinches]

D = Identification area for stamping amounts of

stock

removed

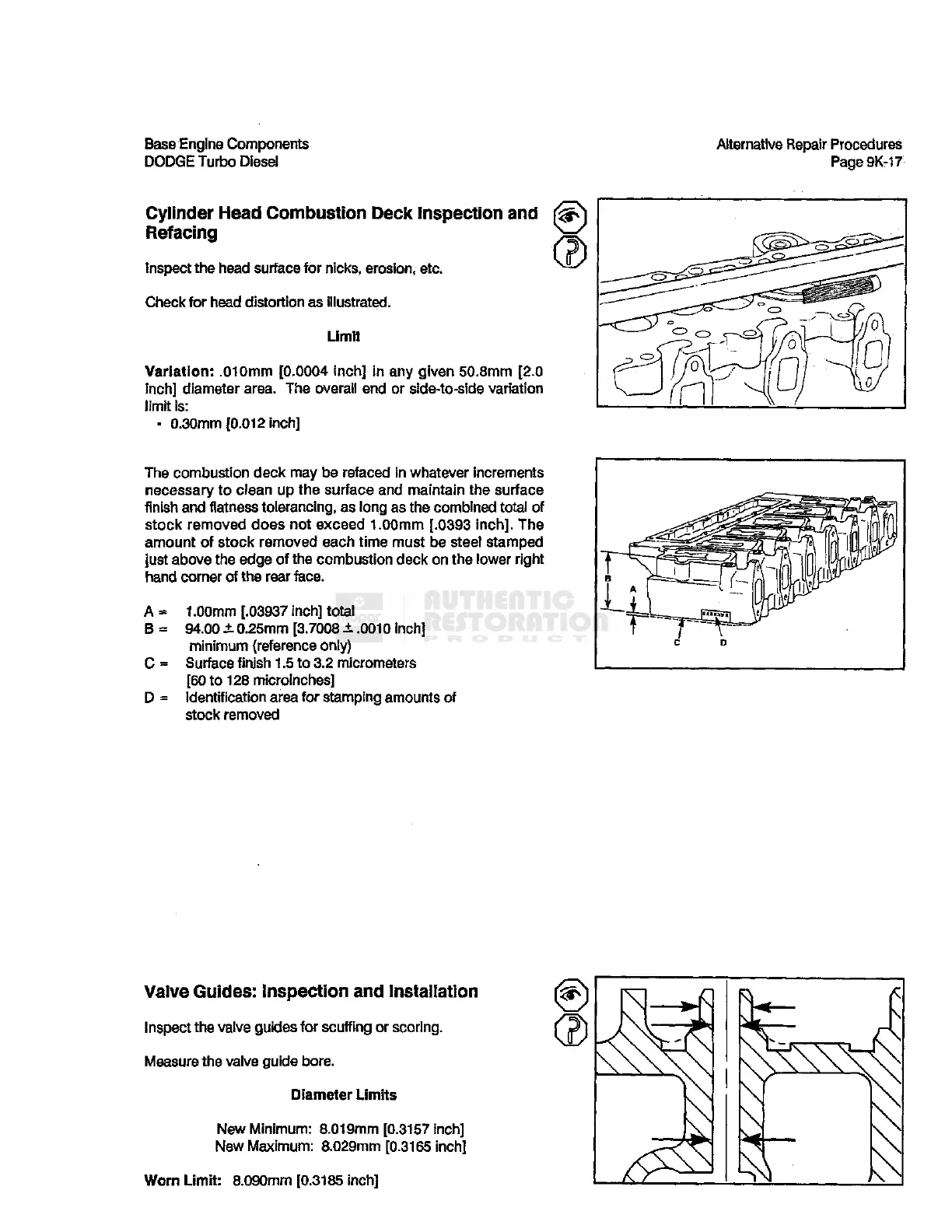

Valve

Guides:

Inspection and Installation

Inspect the valve guides for scuffing or

scoring.

Measure the valve guide bore.

Diameter Limits

New

Minimum:

8.019mm

[0.3157

inch]

New Maximum:

8.029mm

[0.3165

inch]

Worn

Limit:

8.090mm

[0.3185

inch]

Loading...

Loading...