Maintenance Guidelines

PageOC-2

Lubrication and Maintenance

DODGE

Turbo Diesel

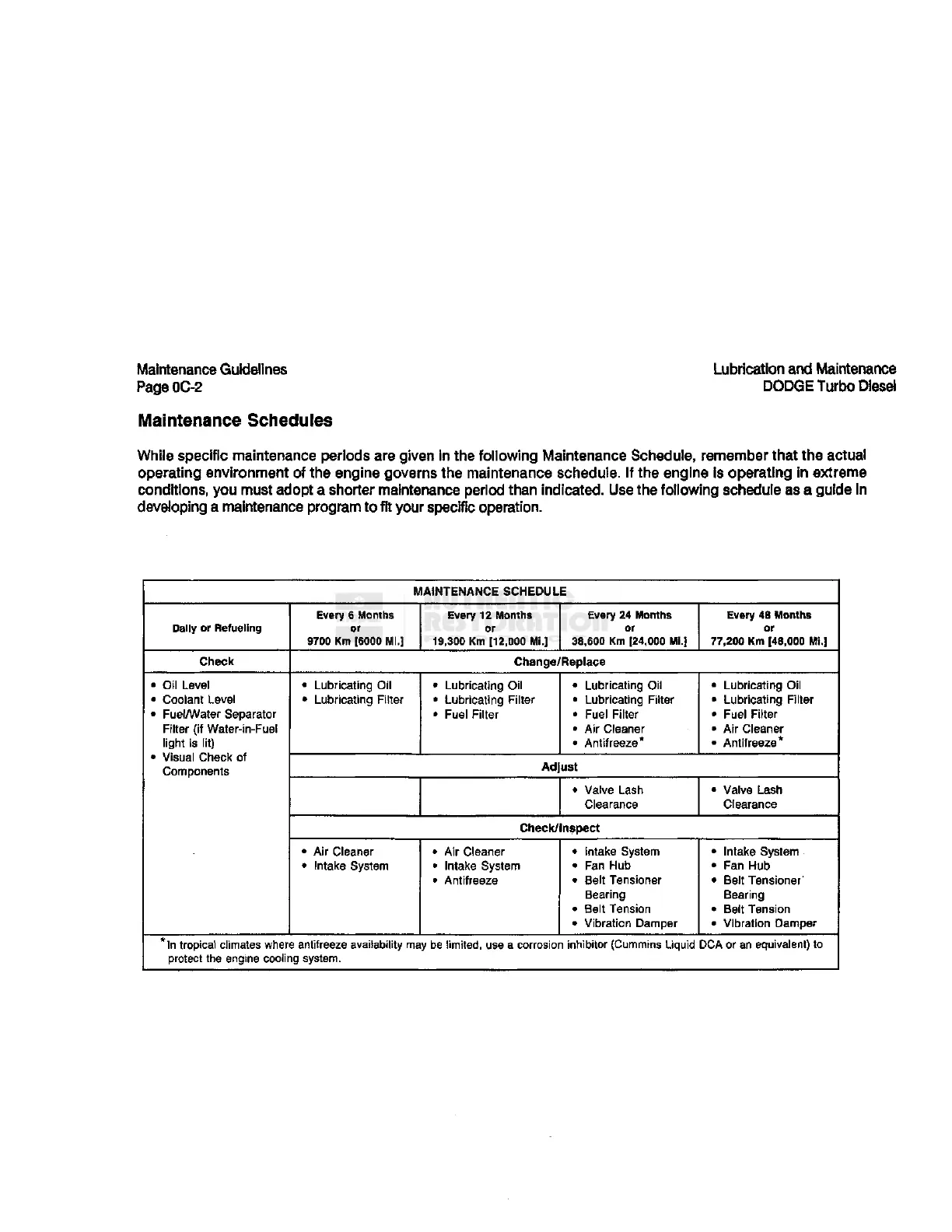

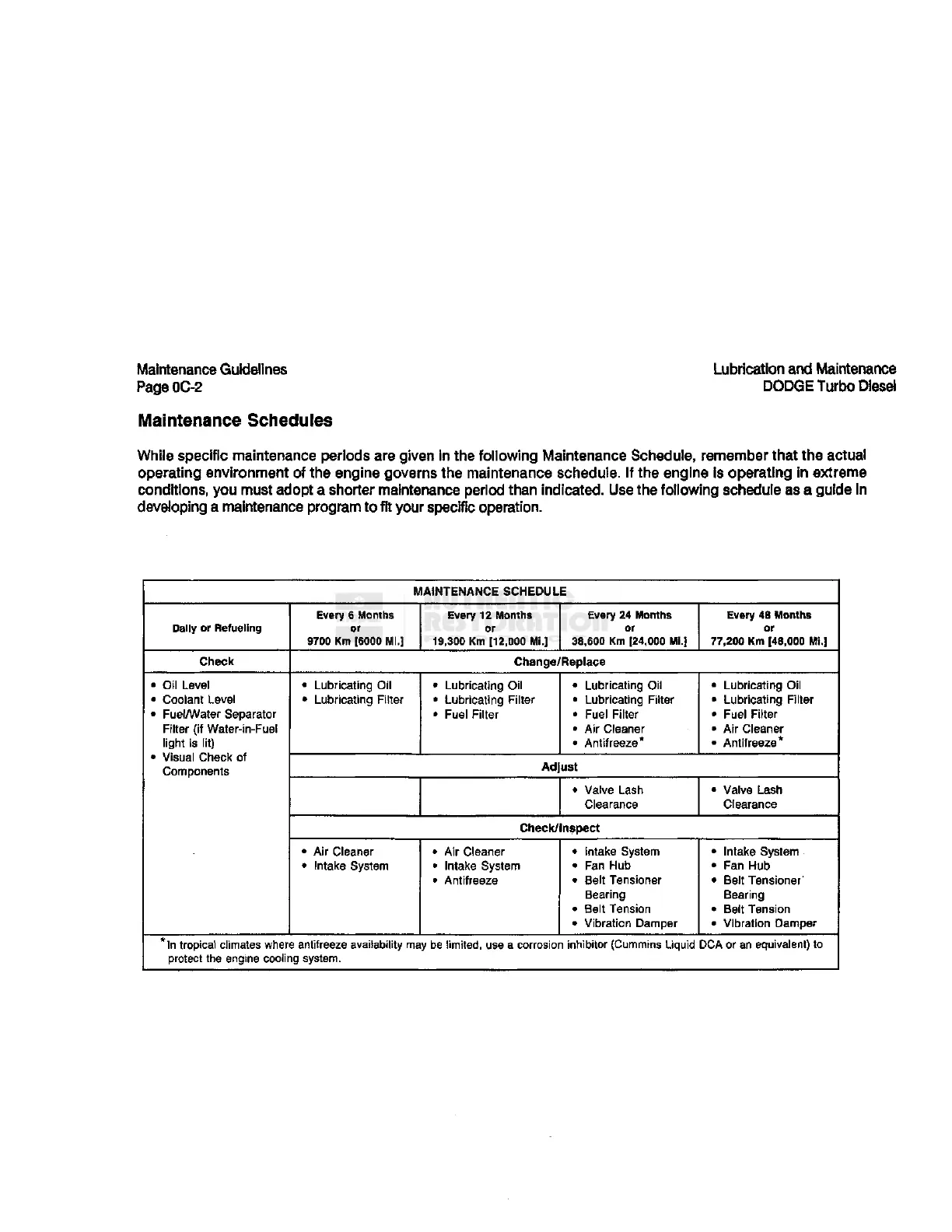

Maintenance Schedules

While specific maintenance periods are given In the following Maintenance

Schedule,

remember

that

the actual

operating environment of the engine governs the maintenance schedule. If the engine is operating in extreme

conditions,

you must adopt a shorter maintenance period than indicated.

Use

the following

schedule

as a guide In

developing a maintenance program to fit your

specific

operation.

MAINTENANCE

SCHEDULE

Daily or Refueling

Every

6 Months

or

9700

Km

[6000

ML]

Every

12 Months

or

19,300

Km

[12,000

Mi.]

Every

24 Months

or

38,600

Km

[24,000

ML]

Every

48 Months

or

77,200

Km

[48,000

ML]

Check

Change/Replace

• Oil Level

• Coolant Level

• Fuel/Water Separator

Filter (if Water-in-Fuel

light

is lit)

• Visual Check of

Components

• Lubricating Oil

• Lubricating Filter

• Lubricating Oil

• Lubricating Filter

• Fuel Filter

• Lubricating Oil

• Lubricating Filter

• Fuel Filter

• Air Cleaner

• Antifreeze*

• Lubricating Oil

• Lubricating Filter

• Fuel Filter

• Air Cleaner

• Antifreeze*

• Oil Level

• Coolant Level

• Fuel/Water Separator

Filter (if Water-in-Fuel

light

is lit)

• Visual Check of

Components

AdJ

ust

• Oil Level

• Coolant Level

• Fuel/Water Separator

Filter (if Water-in-Fuel

light

is lit)

• Visual Check of

Components

• Valve

Lash

Clearance

• Valve

Lash

Clearance

• Oil Level

• Coolant Level

• Fuel/Water Separator

Filter (if Water-in-Fuel

light

is lit)

• Visual Check of

Components

Check/Inspect

• Oil Level

• Coolant Level

• Fuel/Water Separator

Filter (if Water-in-Fuel

light

is lit)

• Visual Check of

Components

• Air Cleaner

• Intake System

• Air Cleaner

• Intake System

• Antifreeze

• Intake System

• Fan Hub

• Belt Tensioner

Bearing

• Belt Tension

• Vibration Damper

• Intake System

• Fan Hub

• Belt Tensioner"

Bearing

• Belt Tension

• Vibration Damper

*ln tropical climates where antifreeze availability may be limited, use a corrosion inhibitor (Cummins Liquid DCA or an equivalent) to

protect the engine cooling system.

Loading...

Loading...