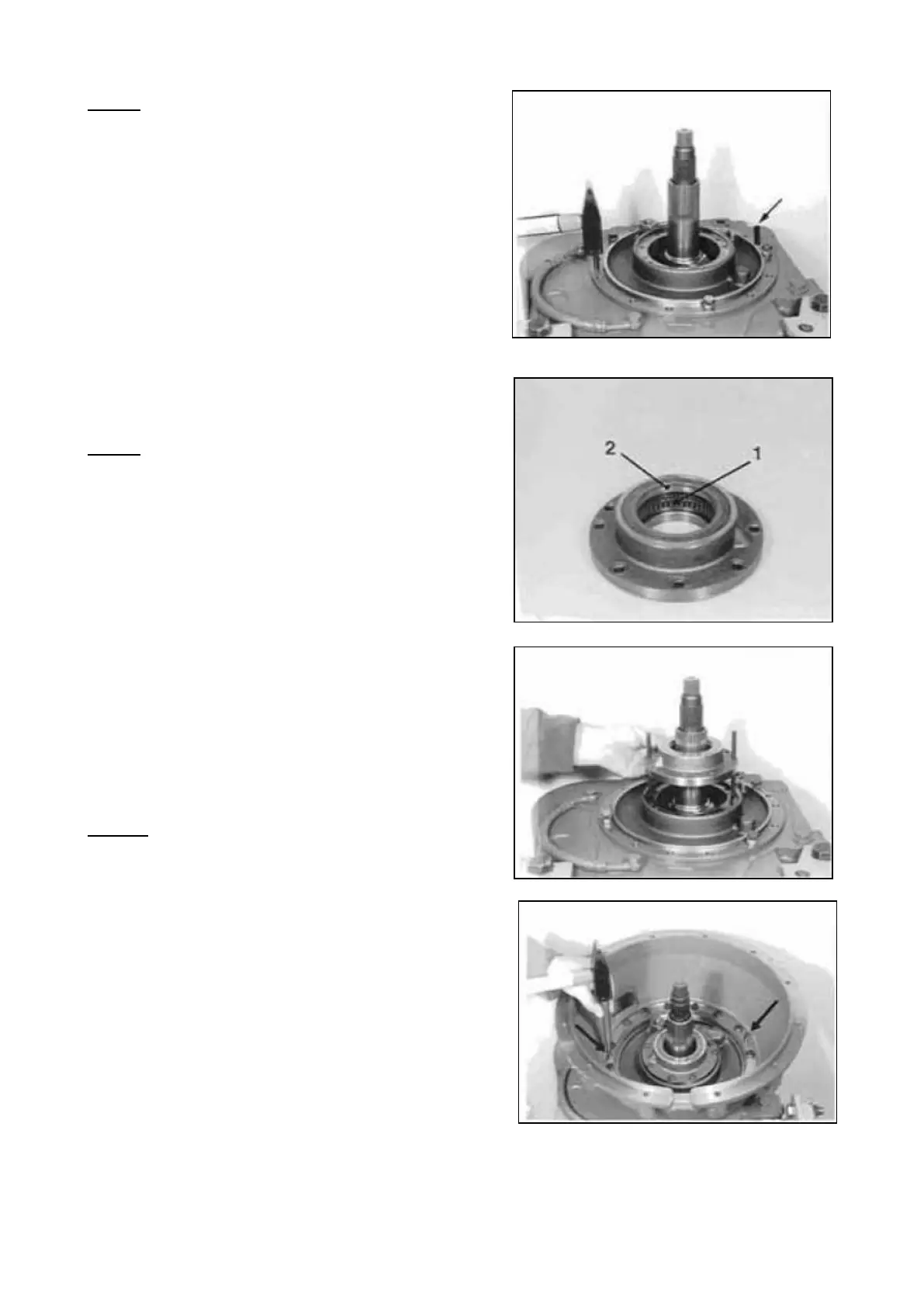

NOTE ;

To ensure an exact sealing of the suction ports and

pressure ports, resp. to avoid the breaking away of

the Loctite, fix oil supply flange by a provisional

installation of the two outer roll pins (10x50 mm) as

well as hex. head screws (3 pieces) radially and

axially, see Figure 259 ! The inner roll pins (6x50

mm) arc installed only after the attachment of the

engine connecting case (Figure 262).

Hardening time of the Loctite about 10…30 minutes.

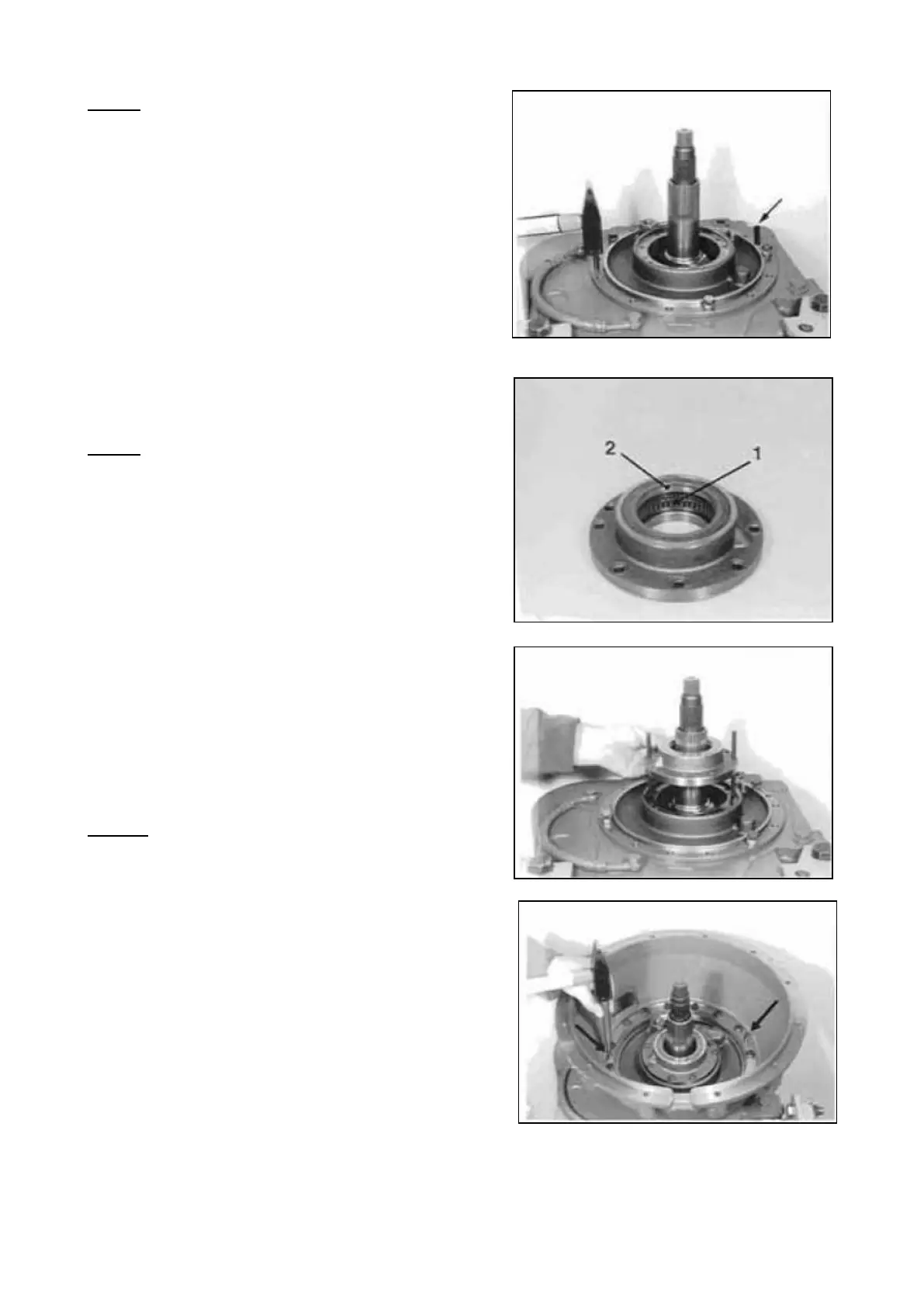

3.2.11 Engine connection

Install needle bearing (1) and shaft seal (2).

NOTE :

The needle bush is marked on one end face.

At the pressing in, the marking must be facing the

drift (upwards) !

The exact installation position is obtained by

application of the prescribed Special Tool.

Wet shaft seal outer diameter with sealing

compound !

( S ) Driver 5870 058 058

( S ) Driver 5870 055 022

( S ) Handle 5870 260 002

Install two adjusting screws and mount flat gasket.

Assemble bearing cap and fasten it by means of

hex. head screws.

Torque limit (M8/8.8) 23 Nm

NOTE ;

Pay attention to the radial installation position!

( S ) Adjusting screws (M8) 5870 204 011

Fasten engine connecting case by means of hex.

head screws and mount the two inner roll pins (6x50

mm).

Torque limit (Ml0/10.9) 68 Nm

SPC000007 Transmission and Torque Converter

Page 158

Loading...

Loading...