to twist adjusting nuts to change position of driven spiral bevel gear (when it is necessary, move active spiral

bevel gear assembly to adjust). If the clearance is larger than the regulated value, approach active spiral

bevel gear from driven spiral bevel gear; otherwise be away from it. In order to keep the adjusted preload of

taper rolling bearing of differential mechanism, twisting numbers of adjusting nuts at one side shall be equal

to twisting numbers of adjusting nuts at the other side.

When adjusting contact zone of spiral bevel gear pair, coat red color (red lead powder) on driven spiral bevel

gear teeth (coat three teeth usually), rotate driven spiral bevel gear with hands repeatedly, check contacting

moulage. Adjust the correct position of spiral bevel gear mesh moulage: it shall not be less than 50% along

with teeth height direction and teeth length direction, mesh moulage of driven bevel gear shall be close to the

center, and in the middle of teeth height, smaller than the small end on teeth length direction. Increasing

preload of differential bearing: after adjusting back lash of spiral bevel gear well, it shall guarantee the

clearance between taper rolling bearing at both sides of differential mechanism is 0. Following is the

adjusting methods.

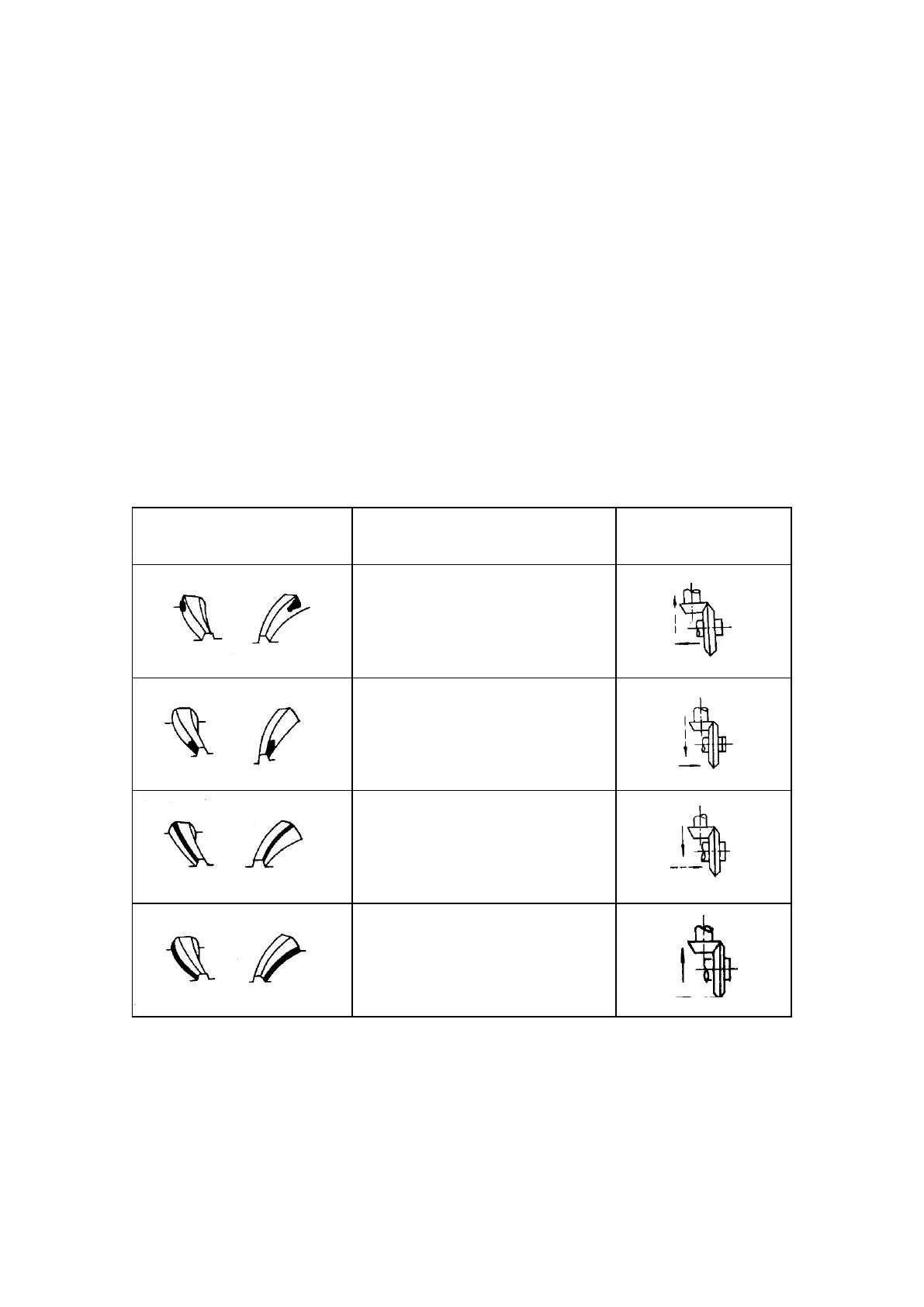

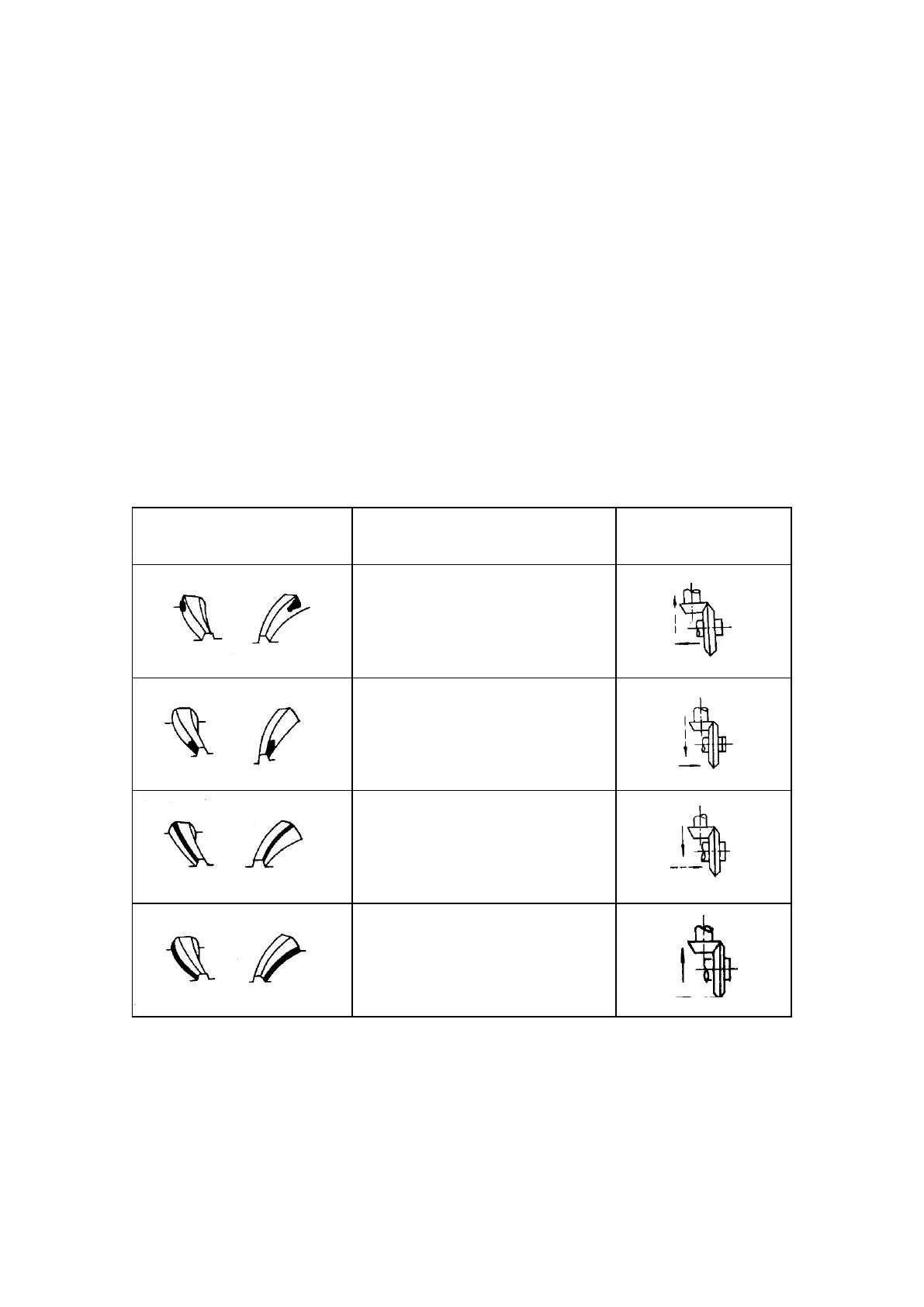

Adjustment of contact zone and back lash when installing spiral bevel gear

Contact zone of driven spiral

bevel gear

Move driven gear to the direction of

active gear, if the clearance is too

small, move active gear outside

Move driven gear away from active

gear, if the clearance is too large,

move active gear inside

Move active gear to the direction of

driven gear, if the clearance is too

small, move driven gear inside and

outside

Move active gear away from driven

gear, if clearance is too large, move

driven gear inside

Method of adjusting mesh zone is usually increasing and decreasing adjusting gaskets and rotating

adjusting nuts. Adjusting of contact zone will affect performance and service life greatly, it shall be carried

out carefully.

Note: After adjusting, clean off red lead powder.

SPC000010 Rear Axle

Page 42

Loading...

Loading...