2018.12.12

© 2017 Eaton. All rights reserved

186

TRSM0940 Service Procedures | Reverse Switch Testing, Removal and Installation

Reverse Switch Testing, Removal and Installation

Special Instructions

The Reverse Switch is a normally open ball switch. When

the transmission is shifted into Reverse, a ramp on the

Reverse Shift Yoke contacts and raises a pin. The pin

depresses the ball on the switch, which closes the switch

contact, allowing current to flow through the switch and

light up the vehicle backup lights.

Special Tools

None

Component Identification

Reverse Switch Testing

1. Disconnect the wiring from the switch by lifting the

connector locking tab and pulling the connector out of

the switch.

2. Connect

an ohm meter to test for continuity.

3. Place the

Transmission Shift Lever in any position

except Reverse. If the switch is working properly, the

ohm meter should read open or infinity. If it is not,

remove the switch and recheck it for continuity.

Replace as necessary.

4. Place the Transmission

Shift Lever in the Reverse posi-

tion. If the switch is working

properly, the ohm meter

should register continuity or a small reading. If it does

not, remove the switch and recheck it for continuity.

Replace as necessary. Also, check for the presence of

the Reverse Pin.

Reverse Switch Removal

1. Disconnect the OEM wiring. Remove the Reverse

Switch using a 22 mm or 7/8” deep well socket or box

end wrench.

2. Check for the presence

of the Reverse Pin in the bore

under the switch.

3. While watching

the Reverse Pin, move the Transmis-

sion Shifter between the Reverse position and any

gear. Th

e pin should raise when the Transmission is

shifted to Reverse and lower when the Transmission is

in Neutral. If the pin does not raise and lower, inspect it

to see if something is causing it to stick, and inspect it

for wear. Also, remove the Shift Tower and check for

wear on the Reverse Yoke Ramp. This ramp can be

seen through the shifter opening.

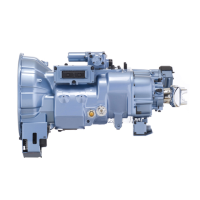

1. Reverse Switch

2. Gasket

3. Actuating Pin

Loading...

Loading...