EBS-6100 Printer User's Manual

Paragraph 4 - Operating the Printer

EBS

Ink-Jet Systems

®

28

20070529#20.5

the correct measurement phasing signal

2

. Therefore vital parameters are measured within the

print head continuously. The settings of these parameters form the so called print head

status and are shown on the terminal display in the printer status window.

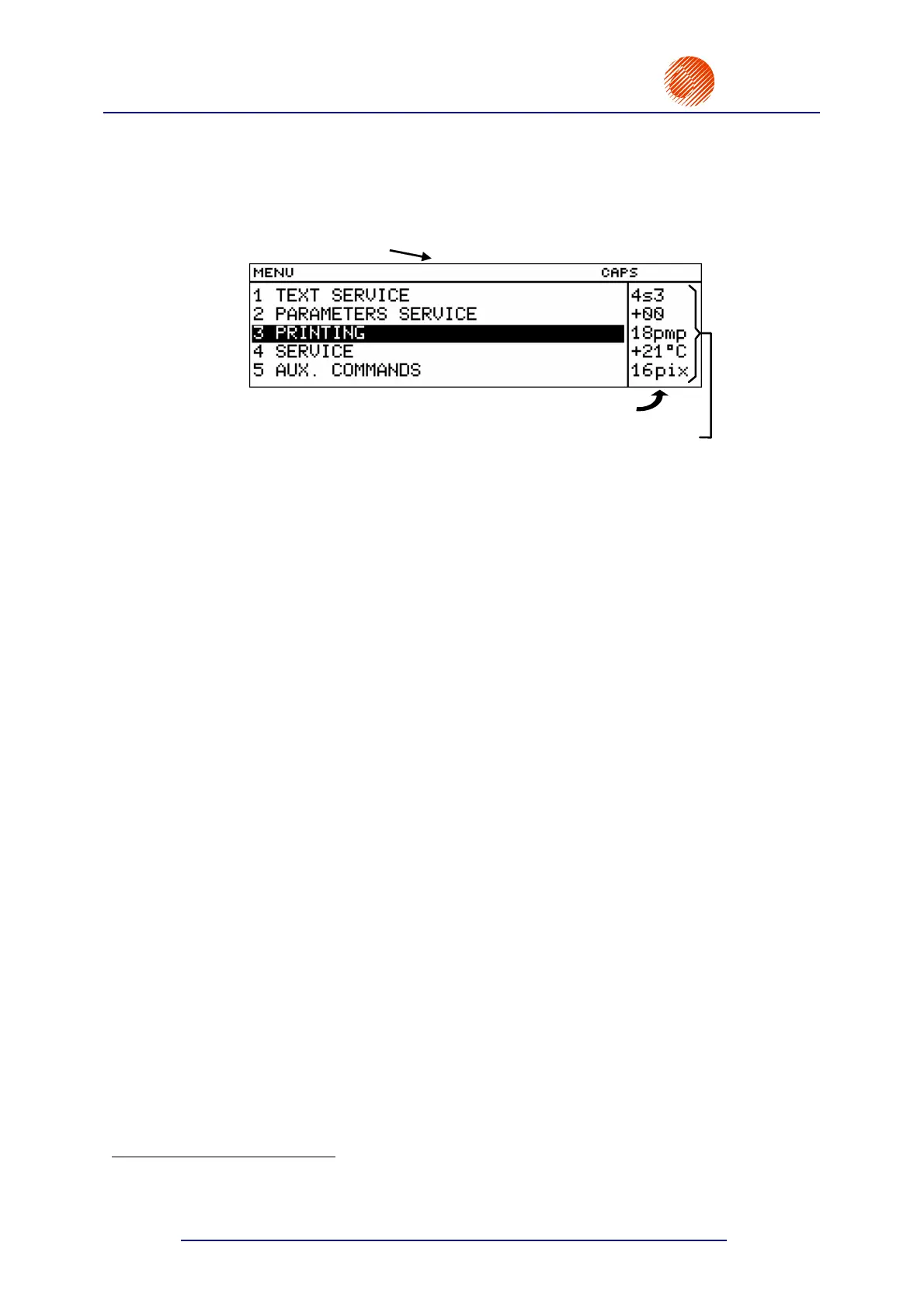

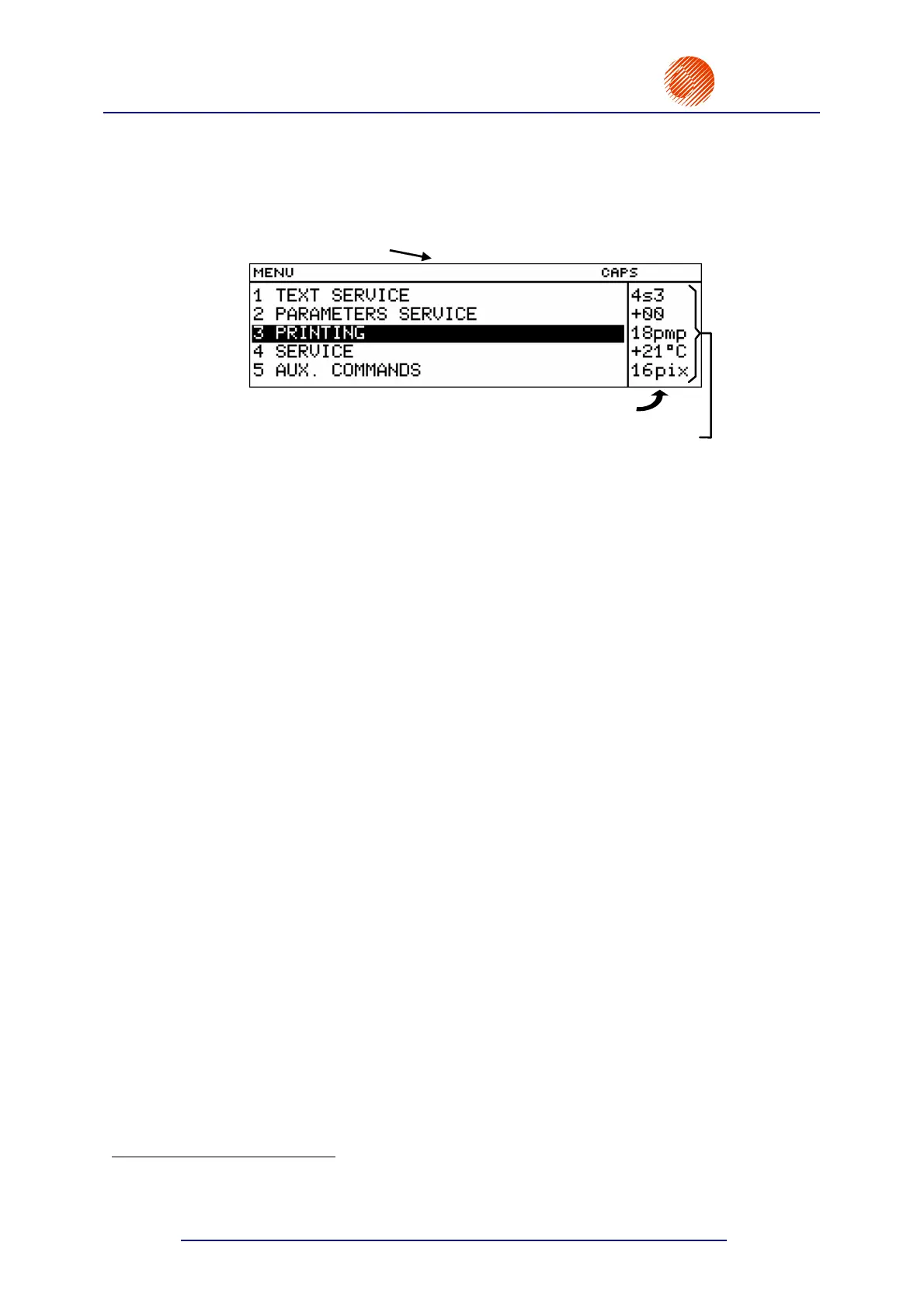

A sample head status is given below.

Graphic display

Printer status window

Head status block

Fig. 4.3.1.

The characters of the status block have the following meaning:

The first digit on the first line indicates the quality of phasing - it can vary between 2 and

6 (with 4 being the optimum). Frequent fluctuations of the quantity from the optimum

indicate that the unit is tuned improperly. A question mark

? which may appear at this

position from time to time means erroneous measurement of phasing. If the mark is

displayed frequently or continuously, this means that the unit is not tuned properly,

especially within the head, and may lead to a phasing error and an alarm.

The second digit on the first line (one character) indicates the head operation mode. The

head can be in one of the following four modes:

r (restart) the head operation has been restarted (no phasing, the printing

disabled, the READY lamp on the internal panel is off),

s (stop) the head is ready to start the printing (phase and ink viscosity are

measured, the READY lamp on the internal panel generates steady light),

p (print) the head performs the operation of printing as the result of the

START PRINT or PRINT SWITCH commands (high voltage is turned on, phase

and viscosity are measured, the READY lamp and the HV lamp on the internal

and external panel generate steady light),

v (service) the head is in service mode and enables the user to perform service

operations (phase and ink viscosity are measured, no alarm is indicated if a

phasing error occurs).

The third digit on the first line (one character) indicates the number of the best phase

determined during the phasing process. It can vary between 0 and 7. Variations in

magnitude every now and again at few-second intervals indicate that ink parameters vary

too quickly (and these are allowed only for a short period after the unit has been switched

on). Changes by ±1 are normal for this parameter.

Three positions on the second line are used to show ink viscosity and other information.

The viscosity is given in relation to its rated value of +00. Positive numbers indicate that

viscosity levels are higher than the rated value, with negative numbers the viscosity is

smaller than the rated value. The correct value ranges between +15 and -05. Two other

characters such as > (<) can be displayed at the position in emergency cases: when ink

viscosity rises (drops) above (below) the value of 99.

The following messages may also occur on the second line:

Per phasing error.

2

Phasing - automatic process of controlling the charging of ink droplets. The breaking point at which a continuous ink jet

breaks into droplets varies slightly with time. Therefore the control system needs to update time relations between

the charging and breaking of an ink jet into droplets on an on-going basis.

Loading...

Loading...