EBS-6100 Printer User's Manual

Paragraph 4 - Operating the Printer

EBS

Ink-Jet Systems

®

88

20070529#20.5

The pulse frequency generated by the internal generator (and thereby the print rate) is

influenced by two print parameters (available with the PRINTING PARAMETERS command

from the PRINTING submenu):

The Cnv spd m/min (see section 4.4.3.5 Print Parameters) parameter adjusts the print

rate (in rows) to the conveyor travel speed (m/min). If the setting of the Cnv spd m/min

parameter does not change and you reduce the travel speed, the density of characters

printed increases.

The setting for the Cnv spd m/min parameter can be determined by measuring travel

speed with the CONVEYER MEASUREMENTS service command - see section

4.4.4.11 Defining Some Print Parameters by Measuring Conveyor Travel Speed.

The Resol. dot/cm (see section 4.4.3.5 Print Parameters) parameter defines image

resolution. The resolution is given as a number of dots/centimetre. The visual effect of

a change to the parameter is a change in the width of characters (graphic images) and

the length of the entire text file.

NOTE:

Extreme setting ranges are specified for Resol. dot/cm and Cnv spd m/min print

parameters. The settings are monitored by the control program on an on-going basis and

may be limited by the settings of other print parameters and setting of the print height (7, 16,

25 or 32 dots). The system is protected automatically against an excessive print rate setting.

Therefore some settings may not be accepted.

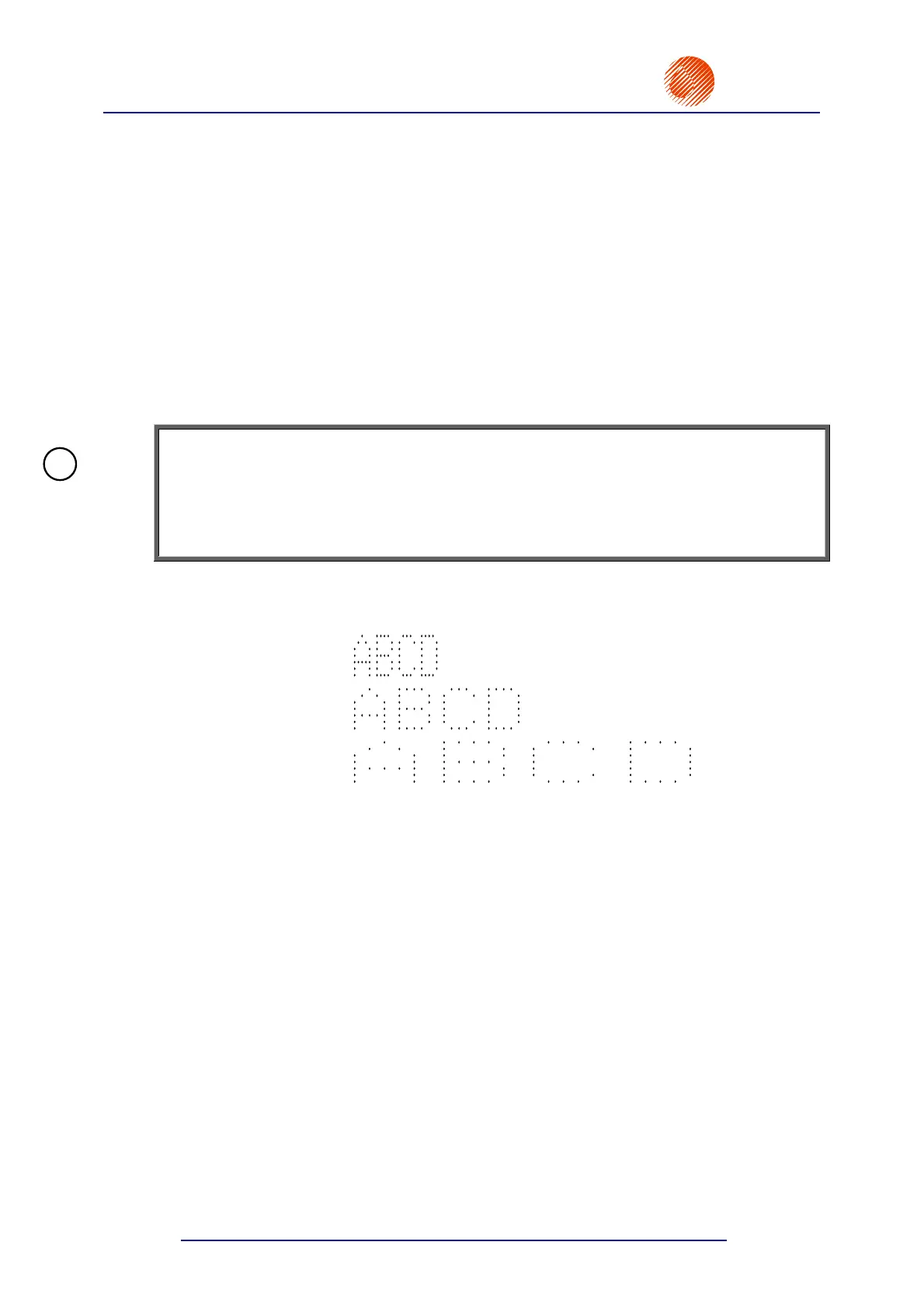

Below you can see a sample print "ABCD" which differs for various settings of the

Resol. dot/cm parameter; the travel speed is constant (NOTE: in order to make the

overprint legible, it is not shown to scale):

Resol. dot/cm:24

Resol. dot/cm:12

Resol. dot/cm:6

Rough measurements of the timing frequency (print rate) can be taken with the

ROWS SPEED command from the PRINTING submenu. The result of the measurement

depends on the settings of the Speed, Generator, Resol. dot/cm and Cnv spd m/min print

parameters from PRINTING.

4.6.2. Shaft-encoder

The shaft-encoder is an electromechanical indicator of rotary speed. The shaft-encoder

axle is coupled mechanically with an object that moves on a factory conveyor, for example.

Pulses are generated at the shaft-encoder output. The pulse frequency is proportional to the

rotational speed of the axle. The pulses determine the moments at which rows of overprints

are to be printed. Therefore the pulse frequency depends on the travel speed, the

transmission ratio of a mechanical gear between the moving product, the shaft-encoder's axle

and the type of encoder, i.e., the number of pulses per rotation. That is why an external

encoder is applied for timing when variable or unstable speed conveyors are used.

!

Loading...

Loading...