EBS

Ink-Jet Systems

®

EBS-6100 Printer User's Manual

Paragraph 4 - Operating the Printe

20070529#20.5

89

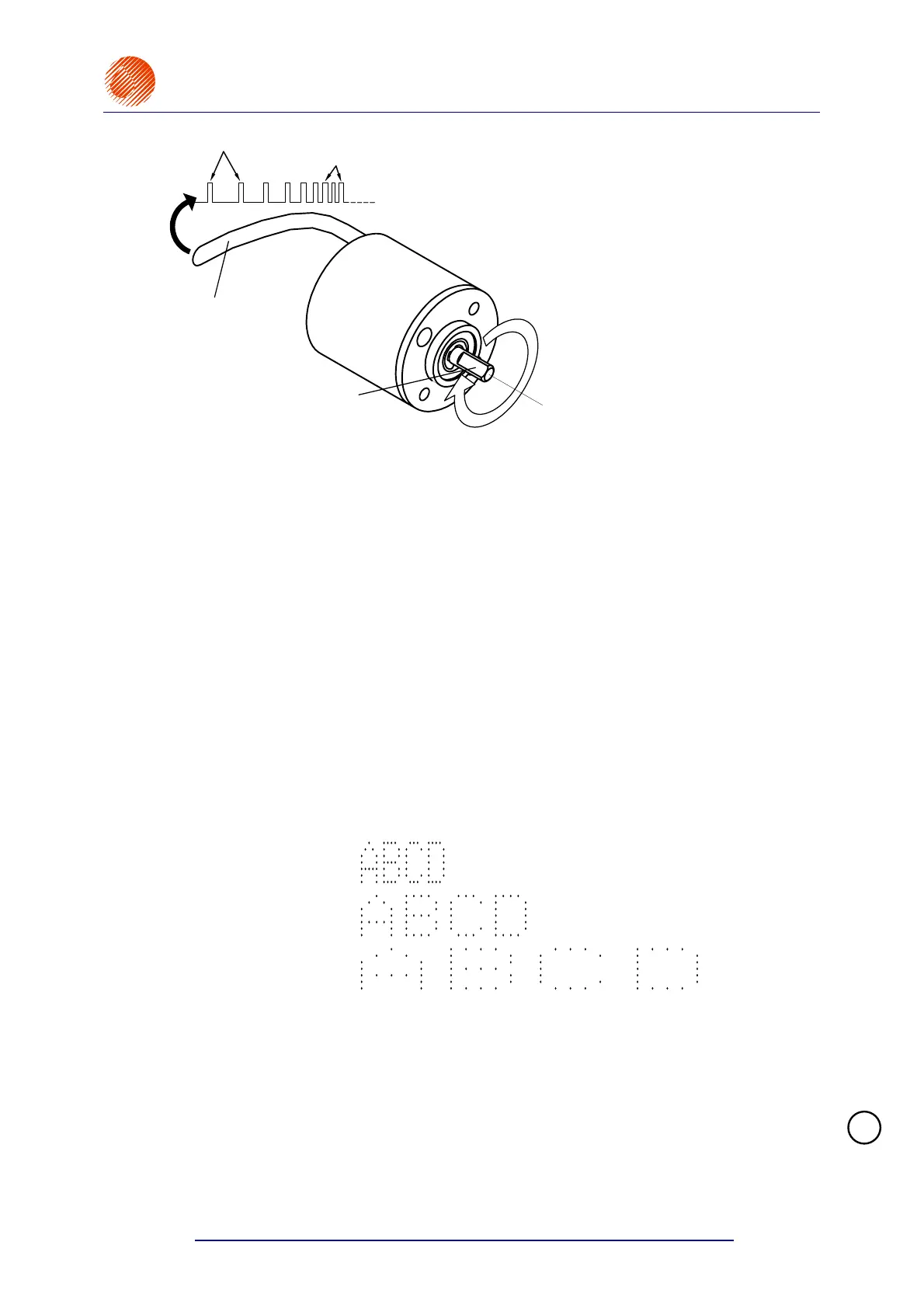

Signal cable

SHAFT-ENCODER axle

Pulses for slow rotation of the SHAFT-ENCODER axle

Pulses for fast rotation of the SHAFT-ENCODER axle

This manual does not

contain any description of

the types of mechanical

gear to be used to couple

mechanically encoders

with conveyors. A variety

of solutions is available

and specific user

requirements can fully be

met.

Fig. 4.6.2.1. Shaft-encoder

The timing frequency (print rate) is influenced by two print parameters (available with the

PRINTING PARAMETERS command from the PRINTING submenu):

The Enc const p/m parameter (see section 4.4.3.5 Print Parameters) parameter defines

the number of pulses generated by the shaft-encoder while the object covers a distance

of 1m. If the shaft-encoder is used for timing purposes and the Enc const p/m parameter

is set to a constant value, no increase or decrease in the conveyor travel speed has any

impact on the characters width.

The setting for the Enc const p/m parameter can be determined by measuring the

encoder constant with the CONVEYER MEASUREMENTS service command - see also

section 4.4.4.11 Defining Some Print Parameters by Measuring Conveyor Travel

Speed.

The Resol. dot/cm parameter (see section 4.4.3.5 Print Parameters) parameter defines

image resolution. The resolution is expressed as a number of dots/centimetre. The visual

effect of a change to the parameter is a change in the width of characters (graphical

images) and the length of the entire text file.

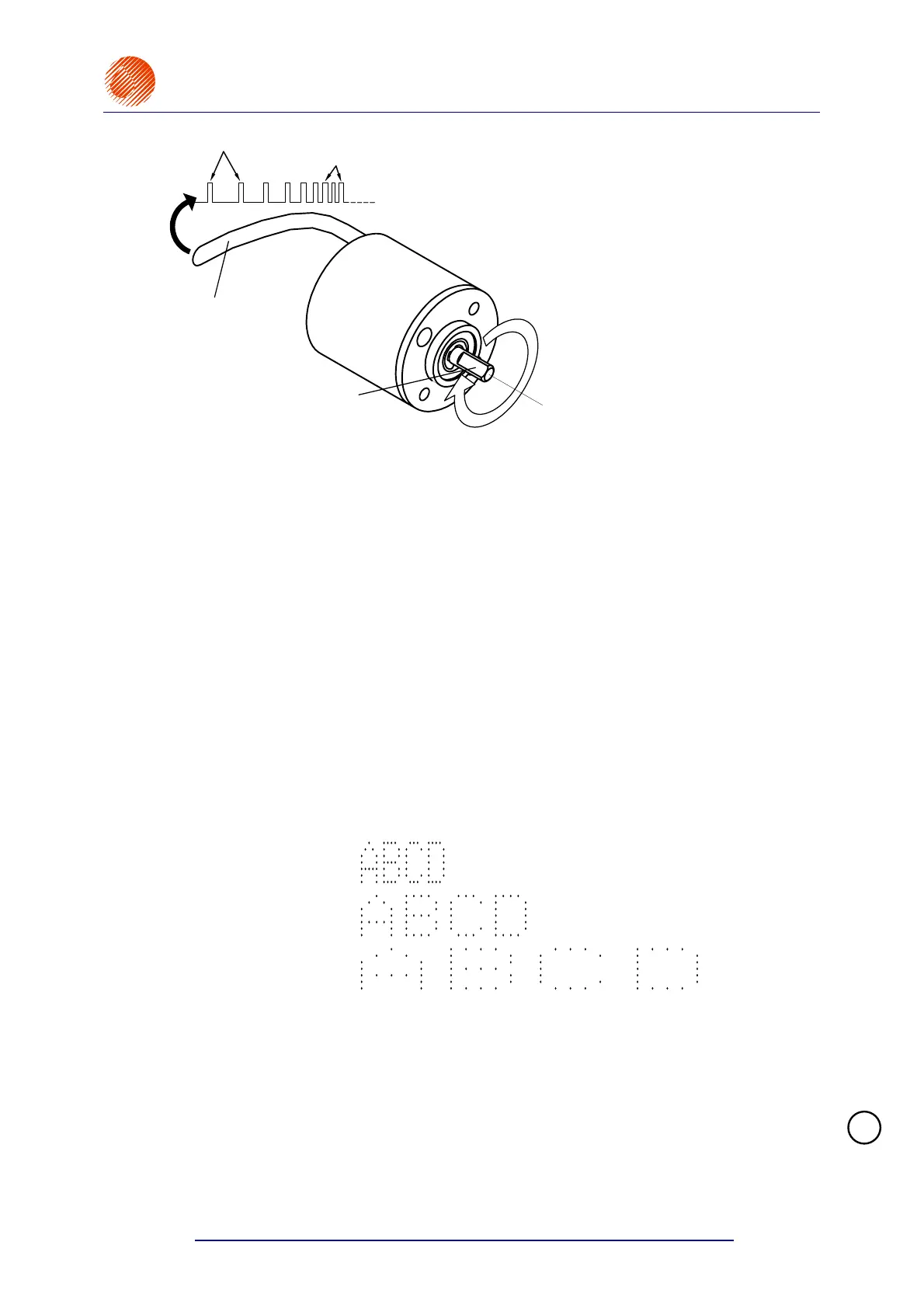

Below you can see a sample print "ABCD" which looks different for various settings of the

Resol. dot/cm parameter; the travel speed is constant (NOTE: in order to make the

overprint legible, it is not shown to scale):

Resol. dot/cm:24

Resol. dot/cm:12

Resol. dot/cm:6

Rough measurements of the timing frequency (in Hz) can be taken with the ROWS SPEED

command from the PRINTING submenu. When the settings are displayed with the application

of the ROWS SPEED command, you can change the rotational speed of the encoder axle (by

changing the transmission ratio) and observe the changes on the terminal display. The

command can also be used when the system works with an internal generator.

As the printer cannot control the frequency of pulses generated by the external encoder, the

allowable settings can be exceeded and the overprint deformed - see section 6.3.9 Some

vertical rows of the print are . In order to avoid such deformation, the timing frequency

should be chosen in such a way that the settings offered by the ROWS SPEED command do

not exceed the maximum print rate. The rate (given in m/min) depends on the font applied

and on print parameters such as Speed, Height, Interleave, Resol. dot/cm. For example, if

!

Loading...

Loading...