Kraftformer KF 170 PD

2018-05-09 | ECKOLD AG 34

With every working stroke of the machine ram the forming tools conduct a work cycle, while

both of the tool halves continuously process the component from above and below.

It is not recommended to make strong curves with high pressure in one passage. If the formation power per

operating cycle is kept small and the component is lead between the tool halves more often, then the forming

can be better controlled and influenced. In addition, the surface of the component is roughenedless.

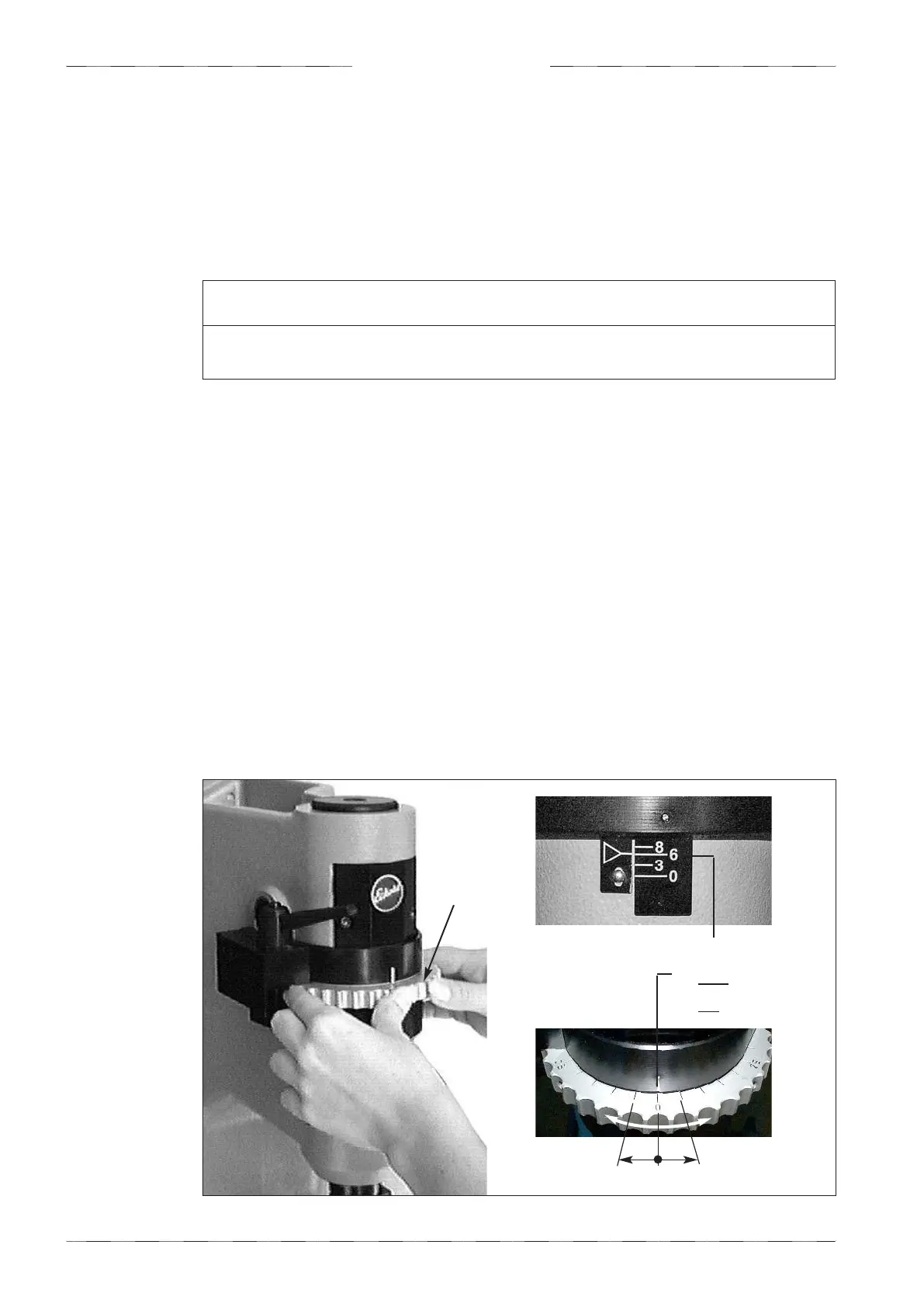

The ram position can be adjusted in height by 8 mm to compensate different tool heights and to preselect

the most suitable position for a short ram stroke (saving time and energy, especially compressed air).

This adjustment does not change the stroke length. This scale shows the basic position.

Fine adjustment in steps of 0.1 mm is shown on the handwheel.

Before you remove the workpiece, lift the ram to release the pressure until the tools are

working free.

This is important to avoid unnecessary wear and tear caused by tool jaw plates

hitting on each other without material in between.

7.5 Adjustable ram position

= 6.0 ram position

6.0

+ 0.0

+/- 0,1 mm

Handwheel

Pic. 7.5 - Adjusting ram postion

iIMPORTANT

Not high working pressure, but the repetition of several operating cycles leads to a

perfect forming.

Operation

Loading...

Loading...