Emerson Process Management GmbH & Co. OHG 3-3

X-STREAM XE

Instruction Manual

HASXEE-IM-HS

10/2012

3

Measuring Principles

3.1.2 NDIR Detector

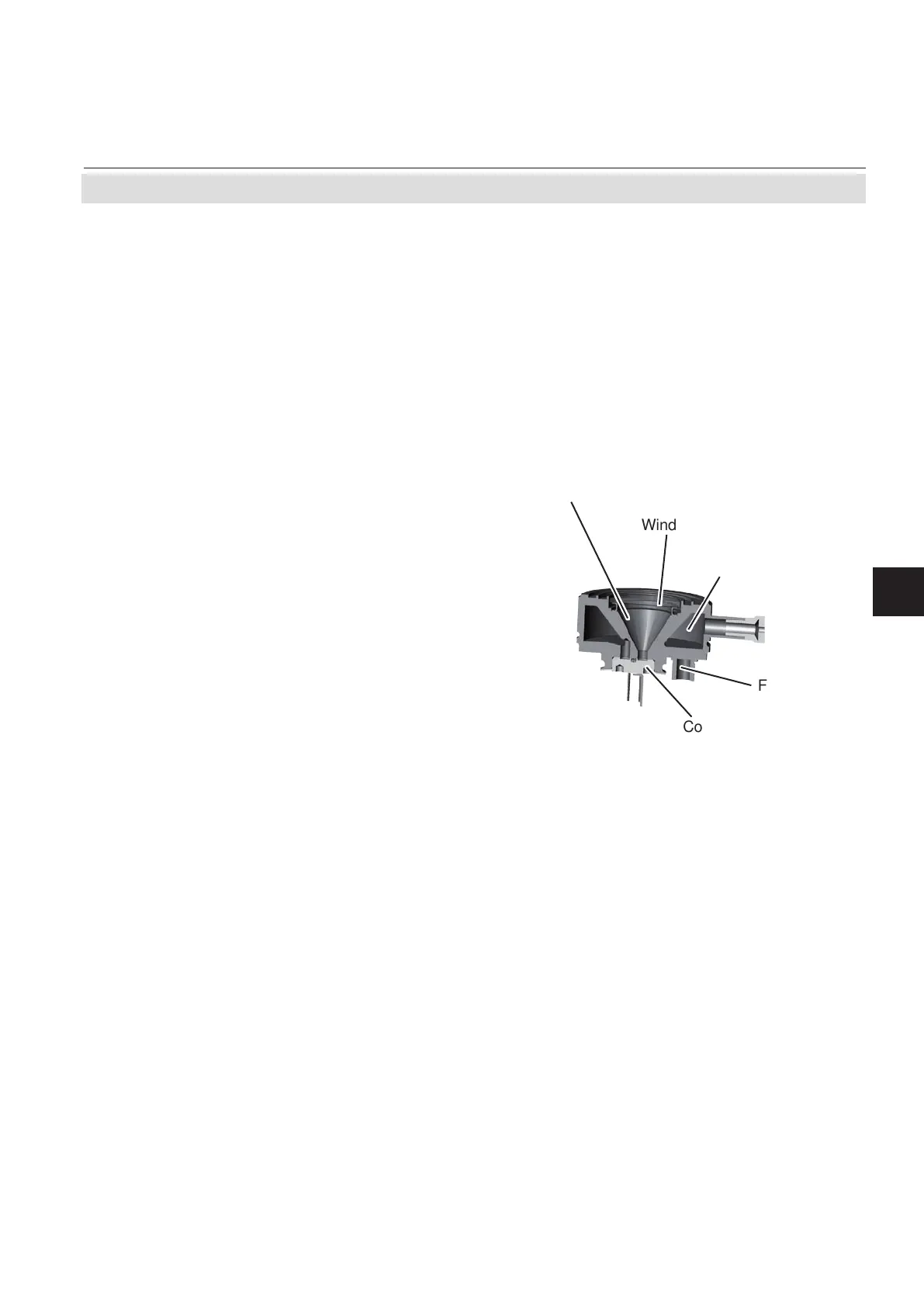

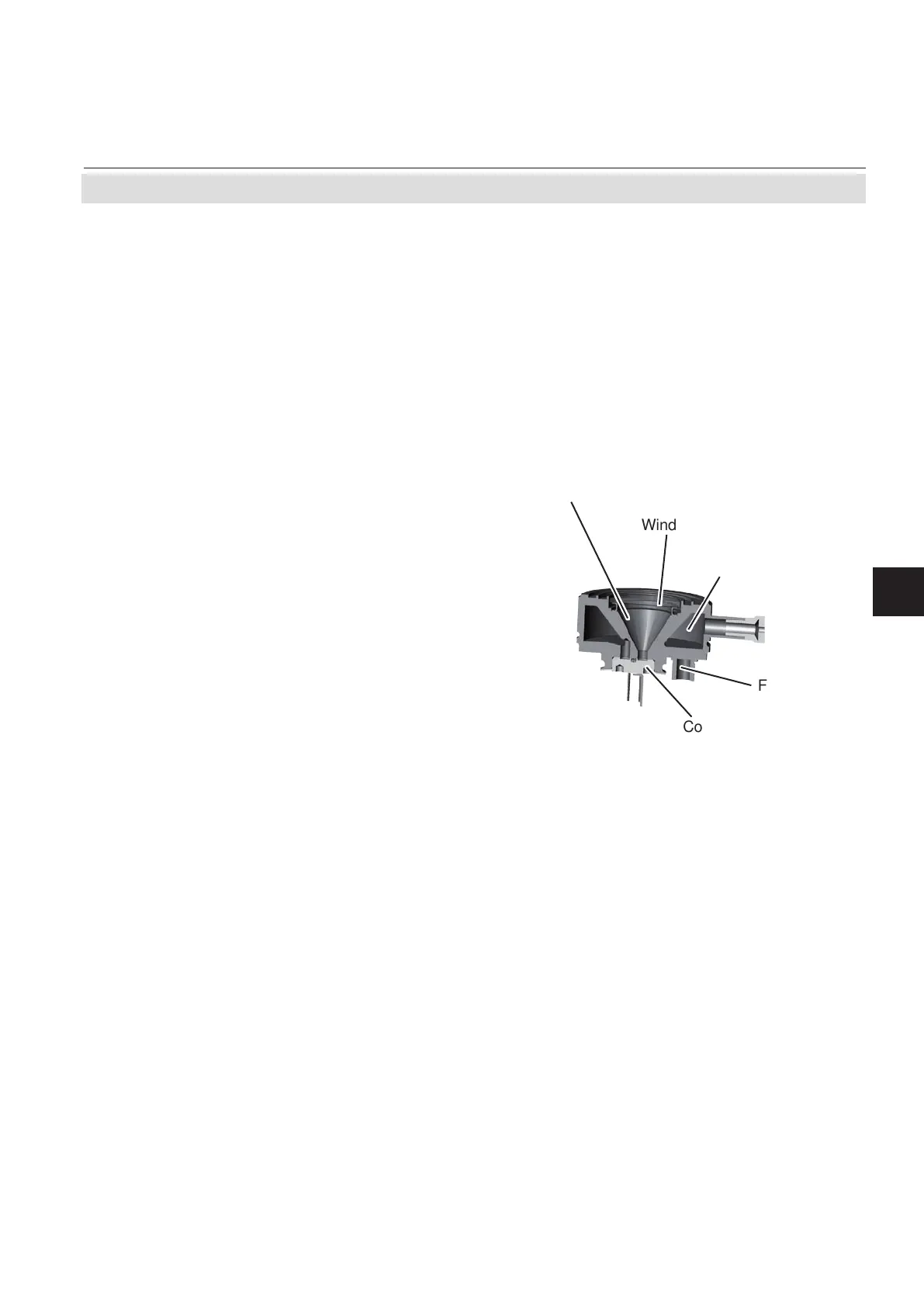

Fig. 3-2: Gas Detector Design Principle

Compensation chamber

Fill nozzle

Absorption chamber

Connecting channel

with

micro ow detector

Window

3.1 Infrared (IR) and Ultraviolet (UV) Measurement

The standard detector used for NDIR measure-

ments is an opto pneumatic detector. It con-

sists of two chambers, lled with gas and

connected via a small channel (Fig. 3-2).

The gas lling is chosen to provide maximum

overlap with the gas to be measured. Usually

the gas to be measured itself is used.

A micro ow sensor, placed in the connecting

channel, measures the ow between both

chambers. As light is absorbed by the gas in

the absorption chamber the gas temperature

changes resulting in an increase of volume of

the heated gas. The gas expands and ows

towards the compensation chamber. When

the chopper closes, no light is absorbed and

thus temperature and volume of the gas in the

absorption chamber decrease. Gas ows back

from the (now) hotter compensation chamber

into the absorption chamber. The absolute

ow, detected by the micro ow sensor, in

both cases is therefore a measure for the

light absorbed while the chopper is open. This

directly correlates to the amount of light not

absorbed in the analysis cell and therefore

to the concentration of the measurement gas

inside the analysis cell.

Using the divided analysis cell and the IntrinzX

chopper wheel enables simultaneous detection

of measurement and reference signal.

Loading...

Loading...