84 Functional description CG Drives & Automation 01-7318-01r1

Adding analogue inputs

If more than one analogue input is set to the same function,

the values of the inputs can be added together. In the

following examples we assume that Process Source [321] is

set to Speed.

Example 1: Add signals with different weight (fine tuning).

Signal on AnIn1 = 10 mA

Signal on AnIn2 = 5 mA

[511] AnIn1 Function = Process Ref.

[512] AnIn1 Setup = 4-20 mA

[5134] AnIn1 Function Min = Min (0 rpm)

[5136] AnIn1 Function Max = Max (1500 rpm)

[5138] AnIn1 Operation = Add+

[514] AnIn2 Function = Process Ref.

[515] AnIn2 Setup = 4-20 mA

[5164] AnIn2 Function Min = Min (0 rpm)

[5166] AnIn2 Function Max = User defined

[5167] AnIn2 Value Max = 300 rpm

[5168] AnIn2 Operation = Add+

Calculation:

AnIn1 = (10-4) / (20-4) x (1500-0) + 0 = 562.5 rpm

AnIn2 = (5-4) / (20-4) x (300-0) + 0 = 18.75 rpm

The actual process reference will be:

+562.5 + 18.75 = 581 rpm

Analogue Input Selection via Digital

Inputs:

When two different external Reference signals are used,

e.g. 4-20mA signal from control centre and a 0-10 V locally

mounted potentiometer, it is possible to switch between

these two different analogue input signals via a Digital Input

set to “AnIn Select”.

AnIn1 is 4-20 mA

AnIn2 is 0-10 V

DigIn3 is controlling the AnIn selection; HIGH is 4-20 mA,

LOW is 0-10 V

“[511] AnIn1 Fc” = Process Ref;

set AnIn1 as reference signal input

“[512] AnIn1 Setup” = 4-20mA;

set AnIn1 for a current reference signal

“[513A] AnIn1 Enabl” = DigIn;

set AnIn1 to be active when DigIn3 is HIGH

“[514] AnIn2 Fc” = Process Ref;

set AnIn2 as reference signal input

“[515] AnIn2 Setup” = 0-10V;

set AnIn2 for a voltage reference signal

“[516A] AnIn2 Enabl” = !DigIn;

set AnIn2 to be active when DigIn3 is LOW

“[523] DigIn3=AnIn”;

set DIgIn3 as input fot selection of AI reference

Subtracting analogue inputs

Example 2: Subtract two signals

Signal on AnIn1 = 8 V

Signal on AnIn2 = 4 V

[511] AnIn1 Function = Process Ref.

[512] AnIn1 Setup = 0-10 V

[5134] AnIn1 Function Min = Min (0 rpm)

[5136] AnIn1 Function Max = Max (1500 rpm)

[5138] AnIn1 Operation = Add+

[514] AnIn2 Function = Process Ref.

[515] AnIn2 Setup = 0-10 V

[5164] AnIn2 Function Min = Min (0 rpm)

[5166] AnIn2 Function Max = Max (1500 rpm)

[5168] AnIn2 Operation = Sub-

Calculation:

AnIn1 = (8-0) / (10-0) x (1500-0) + 0 = 1200 rpm

AnIn2 = (4-0) / (10-0) x (1500-0) + 0 = 600 rpm

The actual process reference will be:

+1200 - 600 = 600 rpm

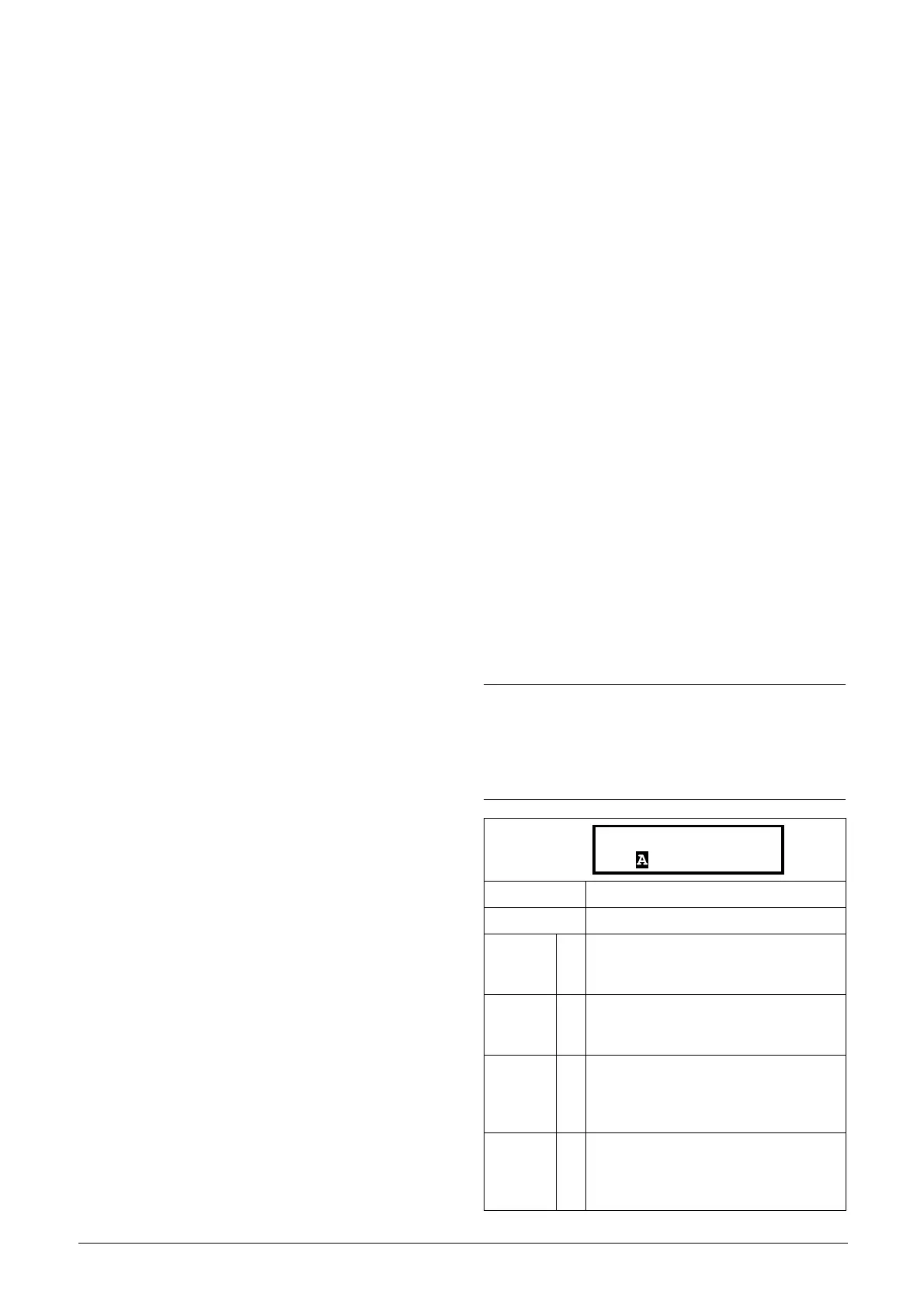

AnIn1 Setup [512]

The analogue input setup is used to configure the analogue

input in accordance with the signal used that will be

connected to the analogue input. With this selection the

input can be determined as current (4-20 mA) or voltage

(0-10 V) controlled input. Other selections are available for

using a threshold (live zero), a bipolar input function, or a

user defined input range. With a bipolar input reference

signal, it is possible to control the motor in two directions.

See Fig. 69.

NOTE:

The selection of voltage or current input is done with

S1. When the switch is in voltage mode only the

voltage menu items are selectable. With the switch in

current mode only the current menu items are

selectable.

Default: User Bipol V

Dependent on Setting of switch S1

4–20mA 0

The current input has a fixed threshold

(Live Zero) of 4 mA and controls the full

range for the input signal. See Fig. 81.

0–20mA 1

Normal full current scale configuration of

the input that controls the full range for the

input signal. See Fig. 80.

User mA 2

The scale of the current controlled input,

that controls the full range for the input

signal. Can be defined by the advanced

AnIn Min and AnIn Max menus.

User Bipol

mA

3

Sets the input for a bipolar current input,

where the scale controls the range for the

input signal. Scale can be defined in

advanced menu AnIn Bipol.

512 AnIn1 Setup

Stp User Bipol V

Loading...

Loading...