Emotron AB 01-3694-01r2 Control Connections 27

4.5.2 Types of control signals

Always make a distinction between the different types of sig-

nals. Because the different types of signals can adversely

affect each other, use a separate cable for each type. This is

often more practical because, for example, the cable from a

pressure sensor may be connected directly to the variable

speed drive.

We can distinguish between the following types of control

signals:

Analogue inputs

Voltage or current signals, (0-10 V, 0/4-20 mA) normally

used as control signals for speed, torque and PID feedback

signals.

Analogue outputs

Voltage or current signals, (0-10 V, 0/4-20 mA) which

change slowly or only occasionally in value. In general, these

are control or measurement signals.

Digital

Voltage or current signals (0-10 V, 0-24 V, 0/4-20 mA)

which can have only two values (high or low) and only occa-

sionally change in value.

Data

Usually voltage signals (0-5 V, 0-10 V) which change rapidly

and at a high frequency, generally data signals such as

RS232, RS485, Profibus, etc.

Relay

Relay contacts (0-250 VAC) can switch highly inductive

loads (auxiliary relay, lamp, valve, brake, etc.).

Example:

The relay output from a variable speed drive which controls

an auxiliary relay can, at the moment of switching, form a

source of interference (emission) for a measurement signal

from, for example, a pressure sensor. Therefore it is advised

to separate wiring and screening to reduce disturbances.

4.5.3 Screening

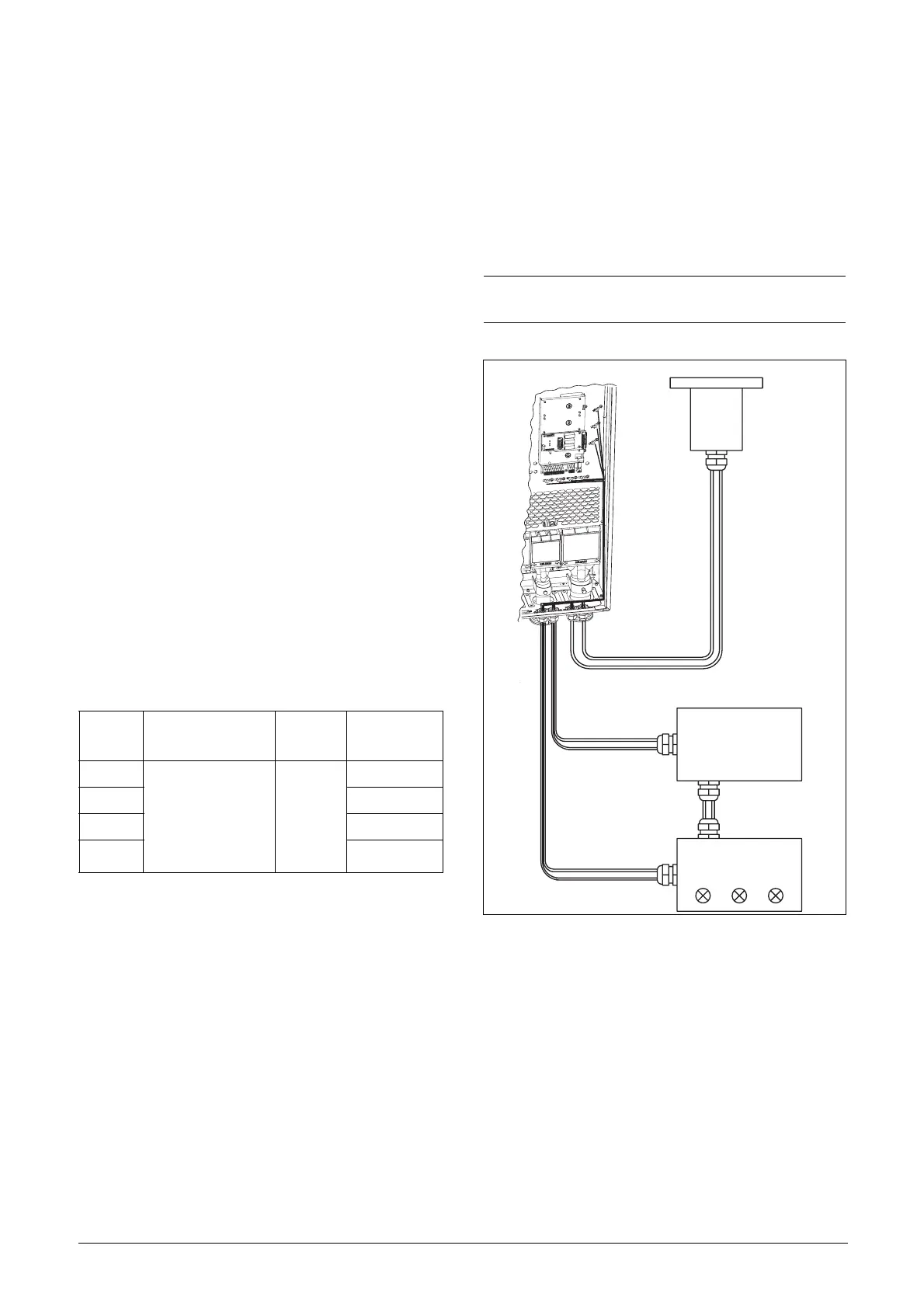

For all signal cables the best results are obtained if the

screening is connected to both ends: the VSD side and the at

the source (e.g. PLC, or computer). See Fig. 30.

It is strongly recommended that the signal cables be allowed

to cross mains and motor cables at a 90° angle. Do not let

the signal cable go in parallel with the mains and motor

cable.

4.5.4 Single-ended or double-ended

connection?

In principle, the same measures applied to motot cables

must be applied to all control signal cables, in accordance

with the EMC-Directives.

For all signal cables as mentioned in section 4.5.2 the best

results are obtained if the screening is connected to both

ends. See Fig. 30.

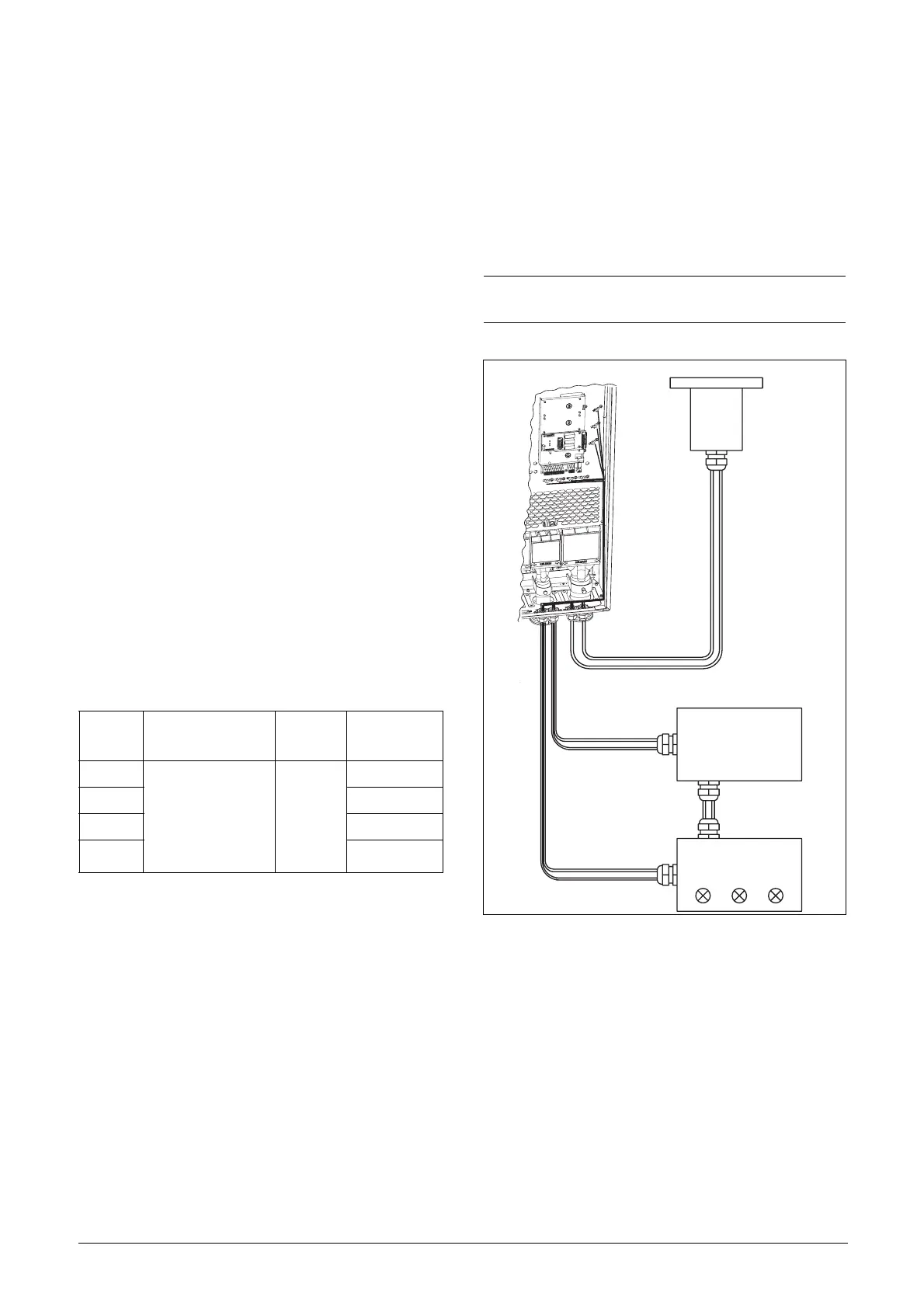

Fig. 30 Electro Magnetic (EM) screening of control signal

cables.

Signal

type

Maximum wire size

Tightening

torque

Cable type

Analogue Rigid cable:

0.14-2.5 mm

2

Flexible cable:

0.14-1.5 mm

2

Cable with ferrule:

0.25-1.5 mm

2

0.5 Nm

Screened

Digital Screened

Data Screened

Relay Not screened

NOTE: Each installation must be examined carefully

before applying the proper EMC measurements.

Control board

Pressure

sensor

(example)

External control

(e.g. in metal housing)

Control consol

Loading...

Loading...