Emotron AB 01-3694-01r2 Functional Description 87

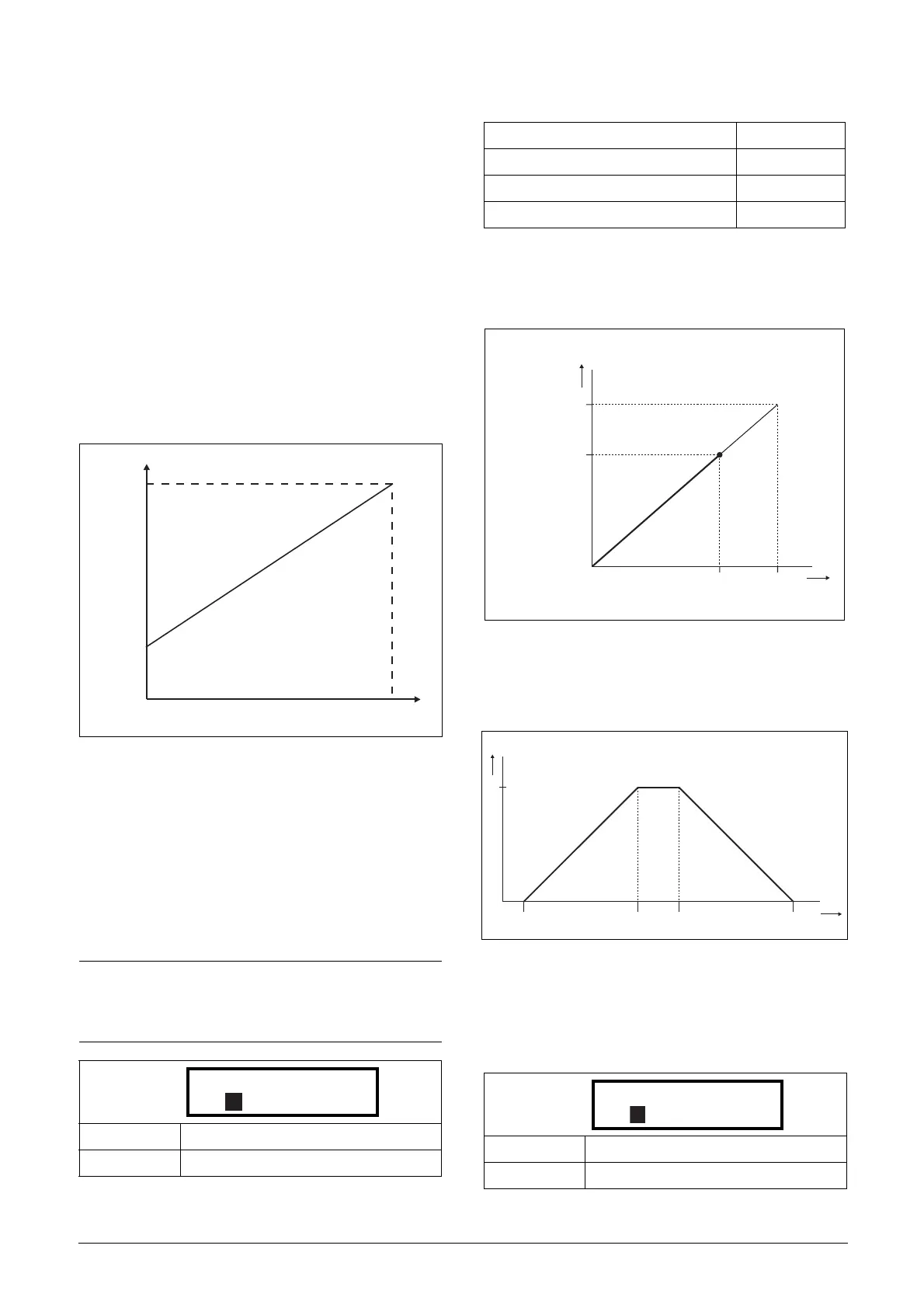

Example

A conveyor belt is used to transport bottles. The required

bottle speed needs to be within 10 to 100 bottles/s. Process

characteristics:

10 bottles/s = 150 rpm

100 bottles/s = 1500 rpm

The amount of bottles is linearly related to the speed of the

conveyor belt.

Set-up:

Process Min [324] = 10

Process Max [325] = 100

Ratio [326] = linear

F(Value), ProcMin [327] = 150

F(Value), ProcMax [328] = 1500

With this set-up, the process data is scaled and linked to

known values which results in an accurate control.

Fig. 71

11.4.3 Start/Stop settings [330]

Submenu with all the functions for acceleration, decelera-

tion, starting, stopping, etc.

Acceleration Time [331]

The acceleration time is defined as the time it takes for the

motor to accelerate from 0 rpm to nominal motor speed.

Communication information

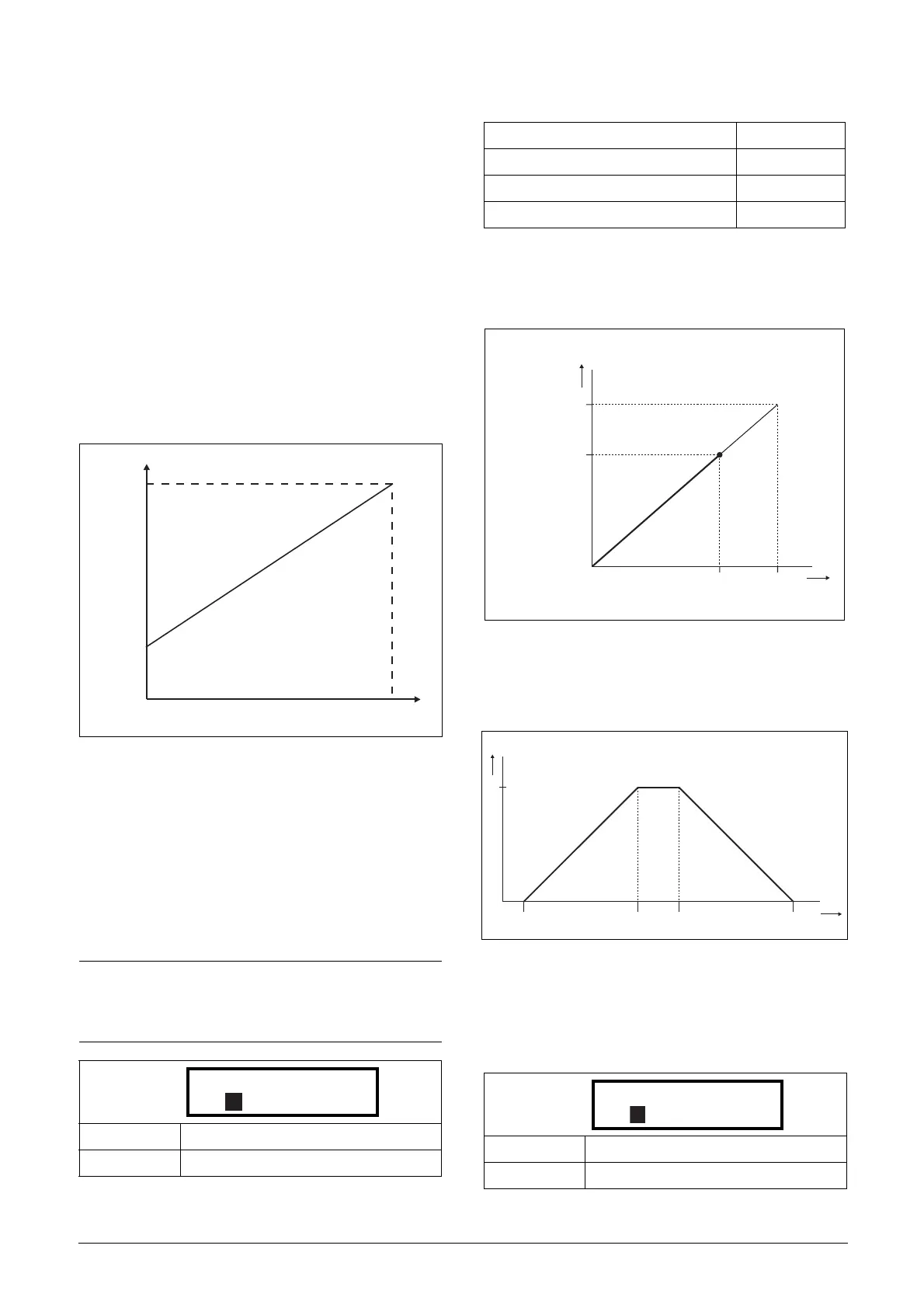

Fig. 72 shows the relationship between nominal motor

speed/max speed and the acceleration time. The same is

valid for the deceleration time.

Fig. 72 Acceleration time and maximum speed

Fig. 73 shows the settings of the acceleration and decelera-

tion times with respect to the nominal motor speed.

Fig. 73 Acceleration and deceleration times

Deceleration Time [332]

The deceleration time is defined as the time it takes for the

motor to decelerate from nominal motor speed to 0 rpm.

NOTE: If the Acc Time is too short, the motor is

accelerated according to the Torque Limit. The actual

Acceleration Time may then be longer than the value

set.

Default: 10.0 s

Range: 0.50–3600 s

F(Value)

PrMax

[328]

1500

150

F(Value

PrMin

[327]

10

Process Min [324]

100

Process Max [325]

Linear

Bottles/s

331 Acc Time

Stp 10.0s

A

Modbus Instance no/DeviceNet no: 43101

Profibus slot/index 169/5

Fieldbus format Long, 1=0.01 s

Modbus format EInt

Default: 10.0 s

Range: 0.50–3600 s

Nominal

Speed

Max Speed

rpm

t

10s8s

(06-F12)

100% n

MOT

80% n

MOT

rpm

(NG_06-F11)

Nom. Speed

Acc Time [331]

Dec Time [332]

332 Dec Time

Stp 10.0s

A

Loading...

Loading...