34 Applications Emotron AB 01-3694-01r2

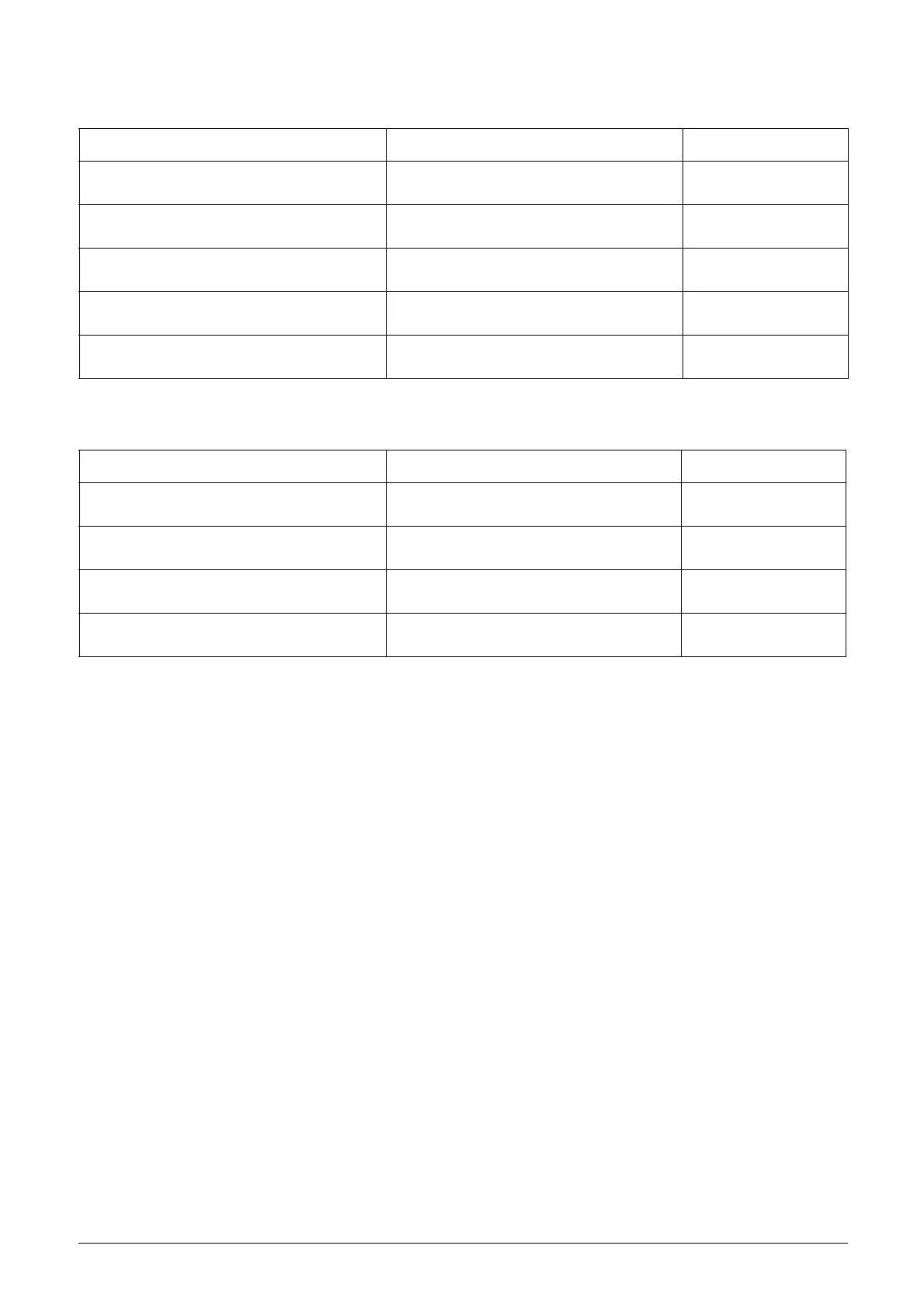

6.1.3Compressors

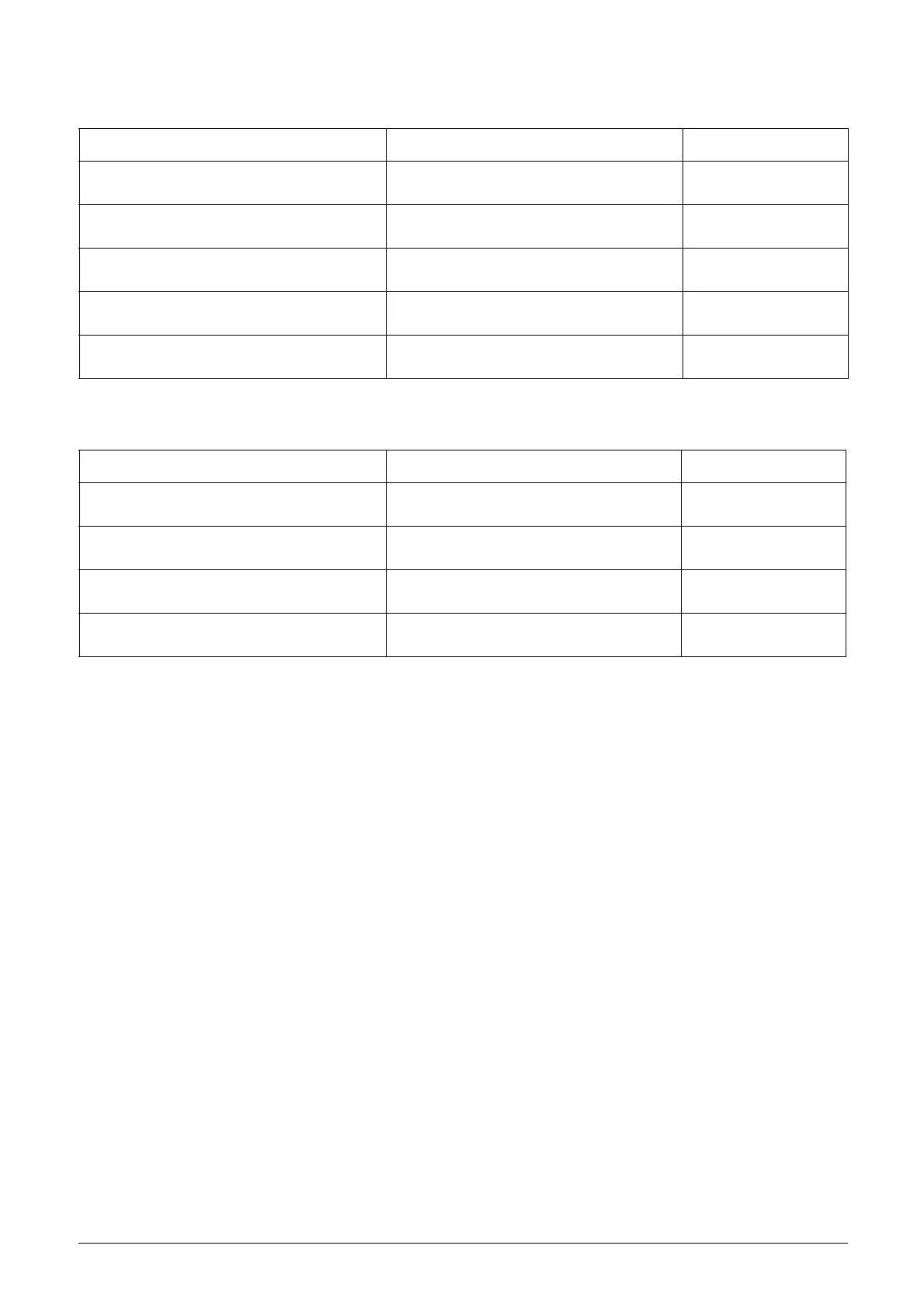

6.1.4Blowers

Challenge Emotron FDU solution Menu

High start currents require larger fuses and cables.

Cause stress on equipment and higher energy cost.

Torque control reduces start current. Same fuses

can be used as those required for the motor.

331– 36, 351

Compressor is damaged when cooling media

enters the compressor screw.

Overload situation is quickly detected and safety

stop can be activated to avoid breakdown.

411–41A

Pressure is higher than needed, causing leaks,

stress on the equipment and excessive air use.

Load Curve Protection function detects deviation.

Warning is sent or safety stop activated.

411–419, 41C–41C9

Motor runs at same speed when no air is com-

pressed. Energy is lost and equipment stressed.

PID continuously adapts to the level required.

Sleep function activated when none is needed.

320, 380, 342, 354

Process inefficiency and energy wasted due to e.g.

the compressor idling.

Load Curve Protection quickly detects deviation.

Warning is sent or safety stop activated.

411–419, 41C–41C9

Challenge Emotron FDU solution Menu

High start currents require larger fuses and cables.

Cause stress on equipment and higher energy cost.

Torque control reduces start current. Same fuses

can be used as those required for the motor.

331–336, 351

Difficult to compensate for pressure fluctuations.

Wasted energy and risk of production stop.

PID function continuously adapts pressure to the

level required.

320, 380

Motor runs at same speed despite varying

demands. Energy is lost and equipment stressed.

PID continuously adapts air flow to level required.

Sleep function activated when none is needed.

320, 380, 342, 354

Process inefficiency due to e.g. a broken damper, a

valve not fully opened or a worn belt.

Load Curve Protection quickly detects deviation.

Warning is sent or safety stop activated.

411–419, 41C–41C9

Loading...

Loading...