Emotron AB 01-3694-01r2 Functional Description 83

11.4 Process and Application

Parameters [300]

These parameters are mainly of the types which are often

adjusted to obtain optimum process or machine perform-

ance.

The read-out depends on the selected process source:

11.4.1 Set/View Reference Value

[310]

View reference value

As default the menu [310] is in view operation. The value of

the active reference signal is displayed. The value is displayed

according to the process unit selected in menu [322].

Set reference value

If the function Reference Control [214] is programmed: Ref

Control = Keyboard, the reference value must be set in

menu [310] with the + and - keys on the control panel. The

ramp times used for this function are according to the set

Acc MotPot [333] and Dec MotPot [334]. Menu [310] dis-

plays on-line the actual reference value according to the

Mode Settings in Table 22.

Communication information

11.4.2 Process Settings [320]

With these functions, the VSD can be set up to fit the appli-

cation. Different functions will ALL use the units that are

standard in the process e.g. bar, rpm or even a user-defined

name. This makes it possible to easily set up the VSD for the

required process requirements, as well as for copying the

range of a feedback sensor to set up the Process Value Mini-

mum and Maximum in order to establish accurate actual

process information.

Process Source [321]

Select the signal source for the process unit (value). The

Process Source can be set to act as a function of the process

signal on AnIn F(AnIn), a function of the motor speed

F(Speed), a function of the shaft torque F(Torque) or as a

function of a process value from serial communication

F(Bus). The right function to select depends on the charac-

teristics and behaviour of the process.

If the selection Speed or Torque is set the VSD will use the

actual speed or torque as reference values.

Example

An axial fan is speed-controlled and there is no feedback sig-

nal available. The process needs to be controlled within fixed

process values in “m

3

/hr” and a process read-out of the air

flow is needed. The characteristic of this fan is that the air

flow is linearly related to the actual speed. So by selecting

F(Speed) as the Process Source, the process can easily be

controlled.

The selection F(xx) indicates that a process unit and scaling

is needed. This makes it possible to e.g. use pressure sensors

to measure flow etc. If F(AnIn) is selected, the source is

automatically connected to the AnIn which has Process

Value as selected.

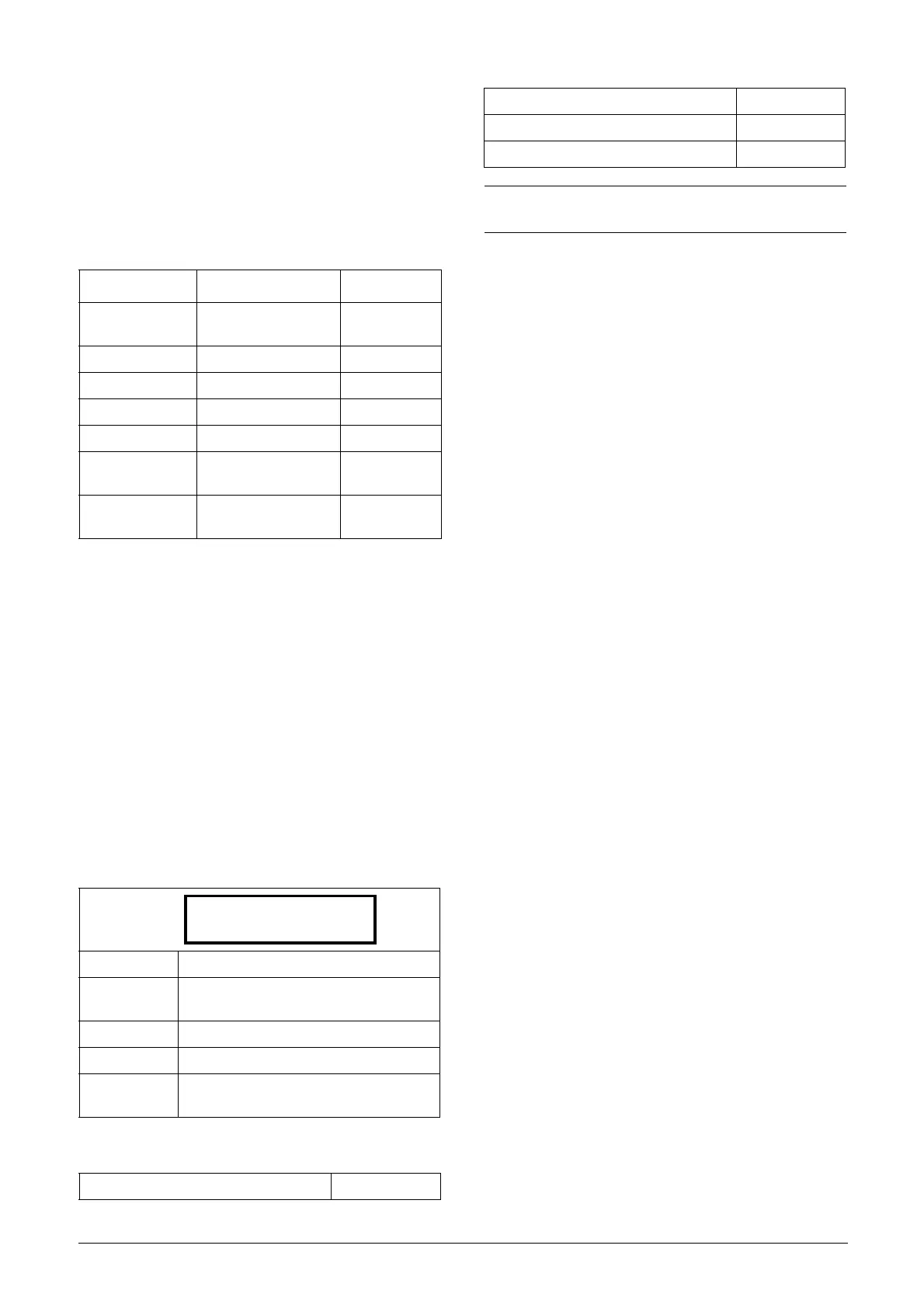

Ta b le 2 2

Mode Read-out: Resolution

Frequency Mode

when [213}=V/Hz

rpm 4 digits

PID Controller % 3 digits

Speed rpm 4 digits

Torque % 3 digits

PT100

°C3 digits

Process Reference

Depends on selected

unit in [322]

3 digits

Process Value

Depends on selected

unit in [322]

3 digits

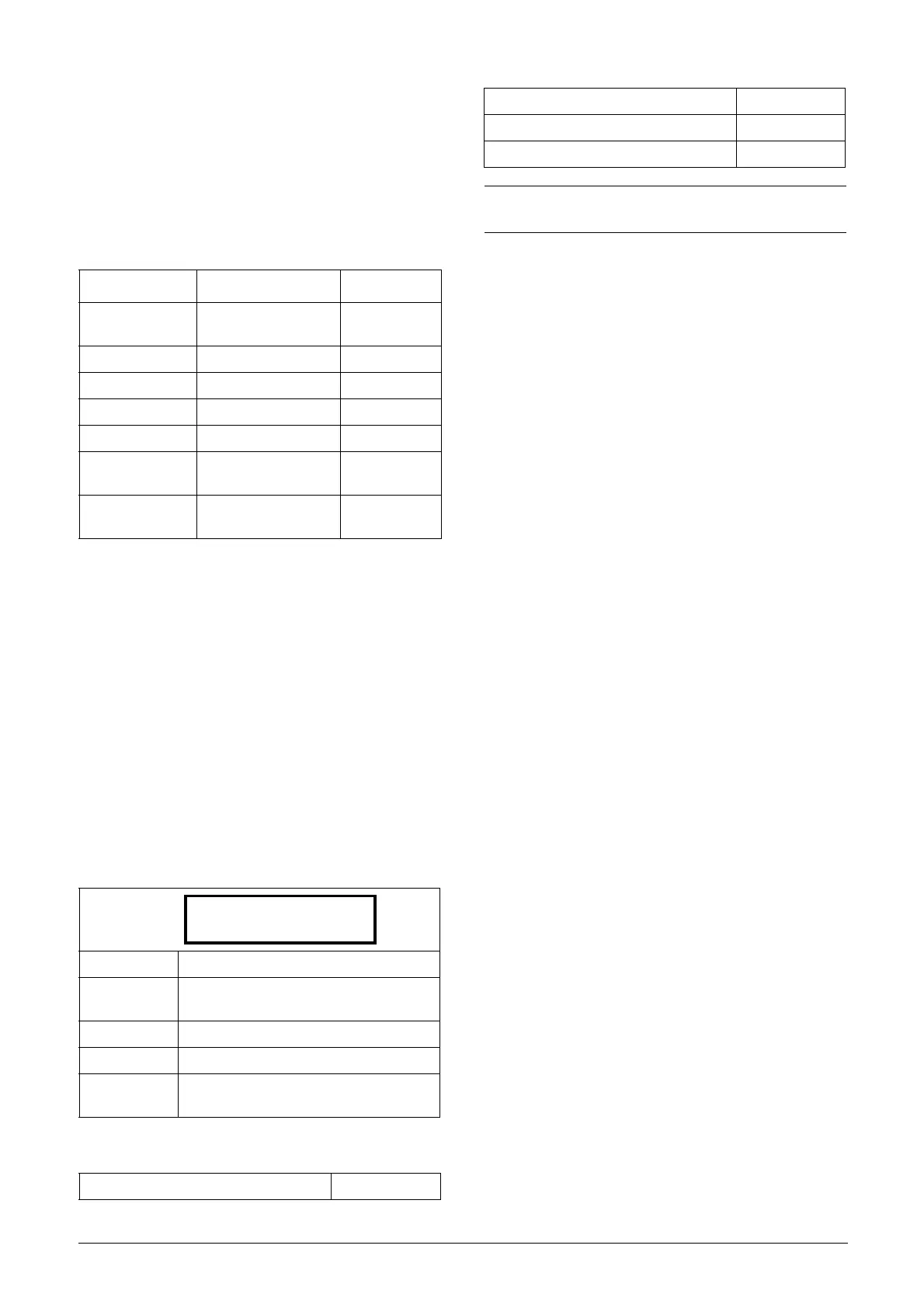

Default: 0 rpm

Dependent on:

Process Source [321] and Process Unit

[322]

Speed mode 0 - max speed [343]

Torque mode 0 - max torque [351]

Other modes

Min according to menu [324] - max accord-

ing to menu [325]

Modbus Instance no/DeviceNet no: 42991

310 Set/View ref

Stp 0rpm

Profibus slot/index 168/150

Fieldbus format Long

Modbus format EInt

NOTE: Modbus data 0-4000H equal zero to maximum

speed.

Loading...

Loading...