Emotron AB 01-3694-01r2 Applications 33

6. Applications

This chapter contains tables giving an overview of many dif-

ferent applications/duties in which it is suitable to use varia-

ble speed drives from Emotron. Further on you will find

application examples of the most common applications and

solutions.

6.1 Application overview

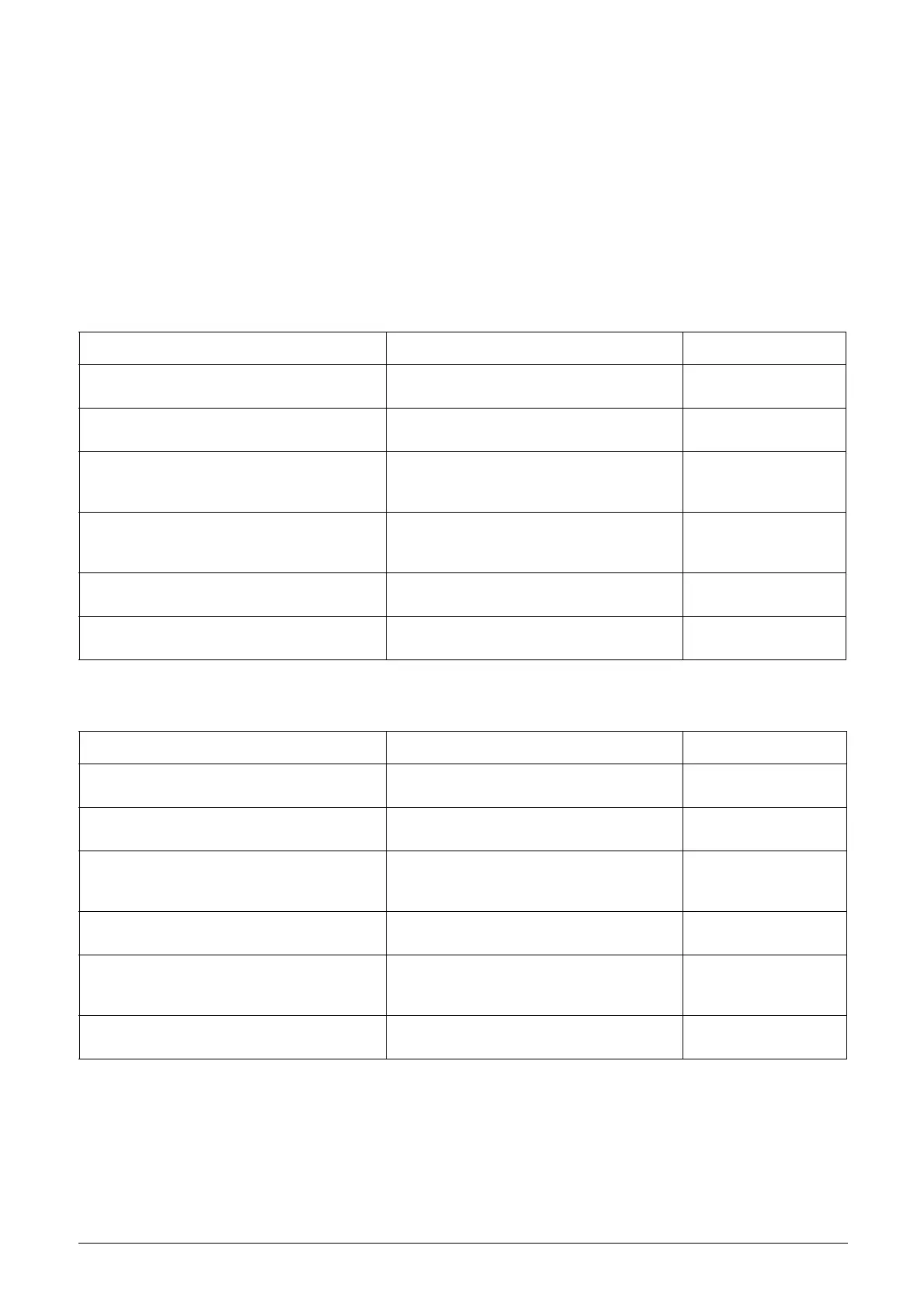

6.1.1Pumps

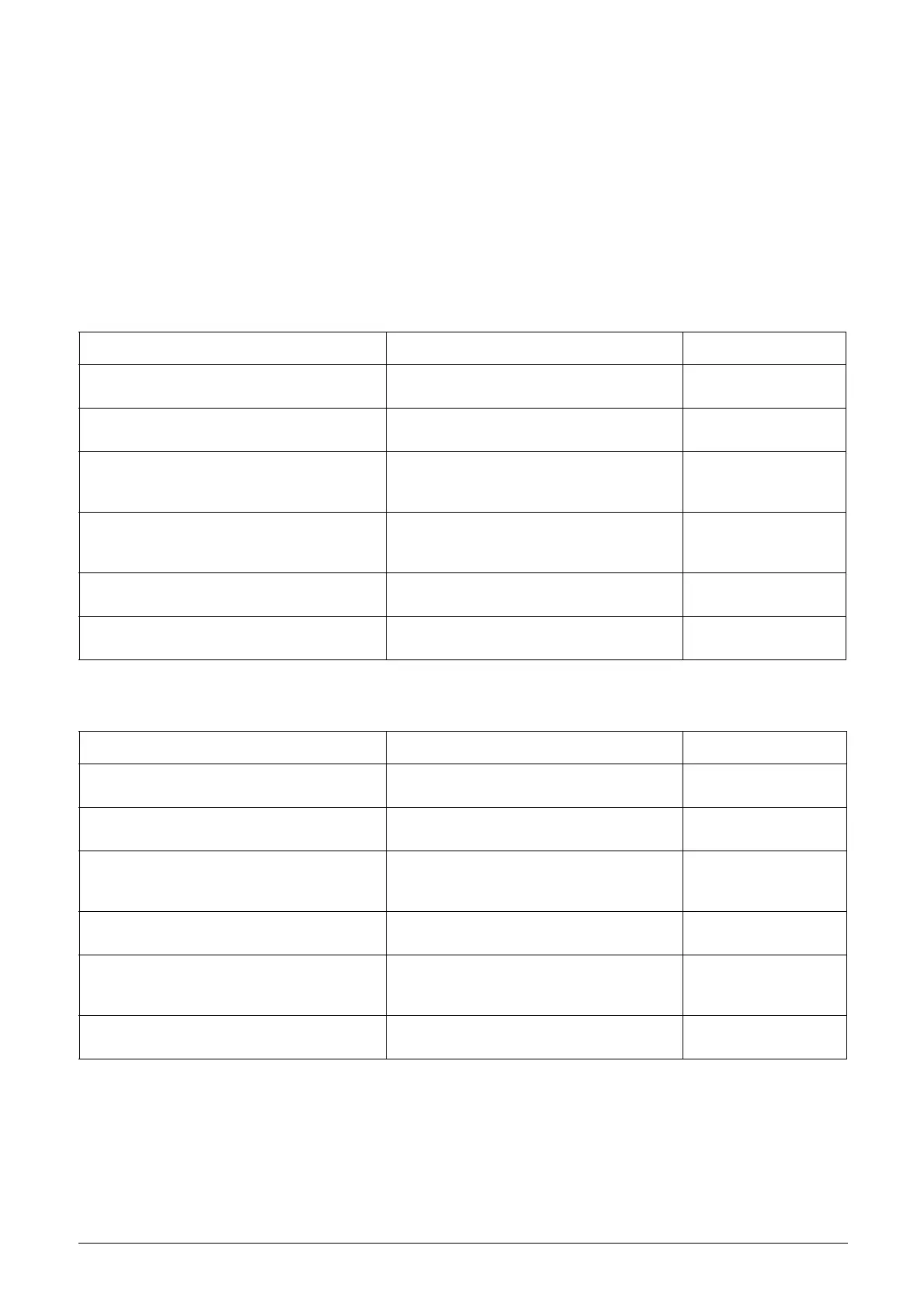

6.1.2Fans

Challenge Emotron FDU solution Menu

High start currents require larger fuses and cables.

Cause stress on equipment and higher energy cost.

Torque control reduces start current. Same fuses

can be used as those required for the motor.

331–336, 351

Dry-running, cavitation and overheating damage

the pump and cause downtime.

Pump Curve Protection detects deviation. Sends

warning or activates safety stop.

411–419, 41C– 1C9

Sludge sticks to impeller when pump has been run-

ning at low speed or been stationary for a while.

Reduces the pump’s efficiency.

Automatic pump rinsing function: pump is set to

run at full speed at certain intervals, then return

to normal speed.

362–368, 560, 640

Motor runs at same speed despite varying

demands in pressure/flow. Energy is lost and

equipment stressed.

PID continuously adapts pressure/flow to the

level required. Sleep function activated when

none is needed.

320, 380, 342, 354

Process inefficiency due to e.g. a blocked pipe, a

valve not fully opened or a worn impeller.

Pump Curve Protection detects deviation. Warn-

ing is sent or safety stop activated.

411–419, 41C–41C9

Water hammer damages the pump when stopped.

Mechanical stress on pipes, valves, gaskets, seals.

Smooth linear stops protect the equipment. Elimi-

nates need for costly motorized valves.

331–336

Challenge Emotron FDU solution Menu

High start currents require larger fuses and cables.

Cause stress on equipment and higher energy cost.

Torque control reduces start current. Same fuses

can be used as those required for the motor.

331–336, 351

Starting a fan rotating in the wrong direction can be

critical, e.g. a tunnel fan in event of a fire.

Fan is started at low speed to ensure correct

direction and proper function.

219, 341

Draft causes turned off fan to rotate the wrong way.

Starting causes high current peaks and mechanical

stress.

Motor is gradually slowed to complete stop before

starting. Avoids blown fuses and breakdown.

219, 33A, 335

Regulating pressure/flow with dampers causes

high energy consumption and equipment wear.

Automatic regulation of pressure/flow with motor

speed gives more exact control.

321, 354

Motor runs at same speed despite varying

demands in pressure/flow. Energy is lost and

equipment stressed.

PID continuously adapts to the level required.

Sleep function is activated when none is needed.

320, 380, 342, 354

Process inefficiency due to e.g. a blocked filter, a

damper not fully opened or a worn belt.

Load Curve Protection detects deviation. Warning

is sent or safety stop activated.

411–419, 41C–41C9

Loading...

Loading...