Disassembly and Assembly

LXXX)

Service

Jl&mual

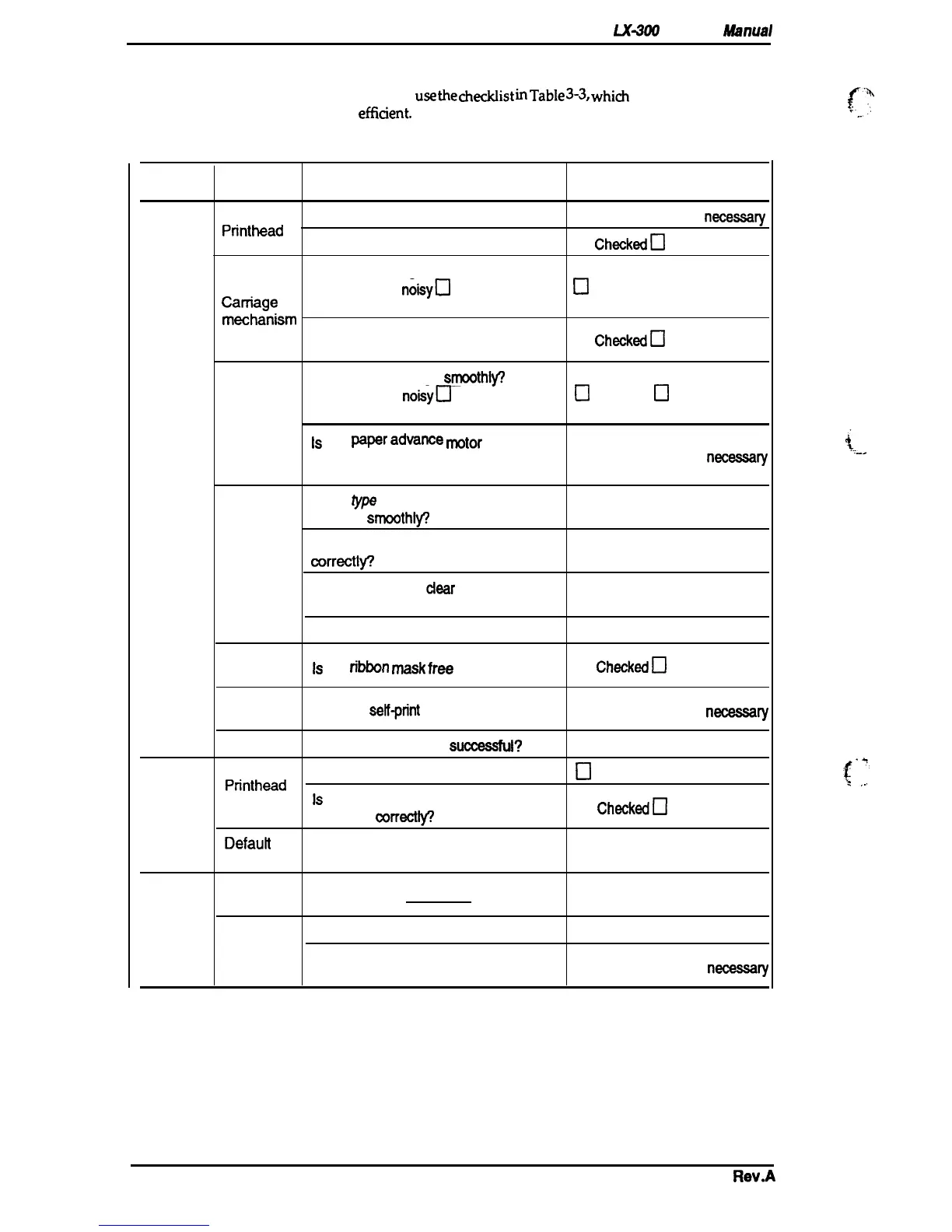

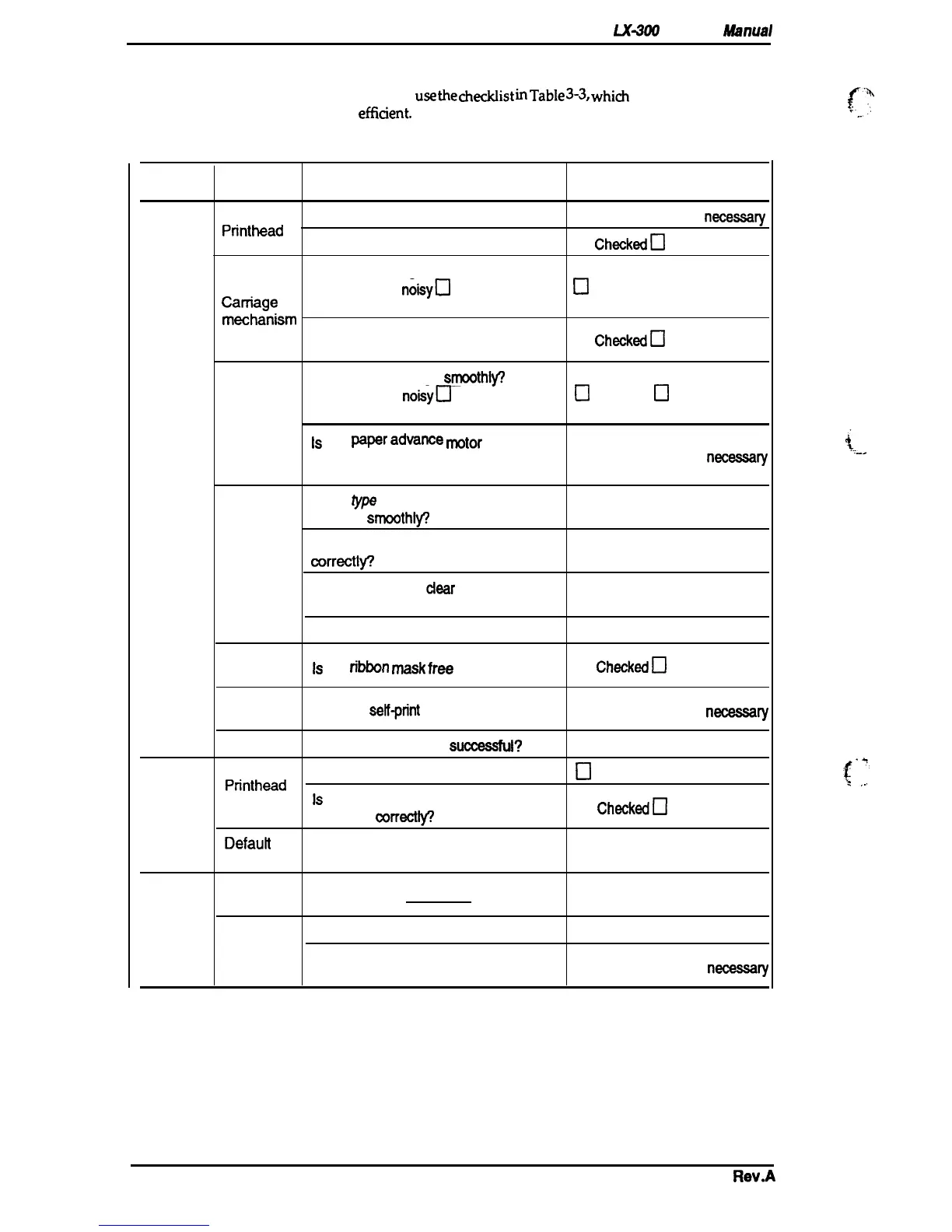

3.1.3 Service Checks After Repair

Before returning the printer after

service,

use

the

checklist

in

Table

3-3,

Whib

provides a record to

make servicing and shipping more

effiaent.

Table 3-3. Inspection Checklist for Repaired Printer

Category

Component

Item to

Check

Is Check Required?

Are

any wires broken?

❑

Chsck@

❑

Not

necessq

Printhead

Are

any wires worn out?

❑

Checkedn

Not necessary

Does the carriage move smoothly?

~amage

❑

Movement

noisyn

Mechanism dirty

D

Checked

❑

Not necessary

mwhanism

❑

Mechanism oily

Is the CR motor assembly at the

❑

Checkeda

Not necessary

correct temperature (not overheating)

Is paper advancing smooth~

❑

Movement

noiayu

Mechanism dirty

D

Checked

H

Not necessary

Paper

❑

Mechanism oily

advance

mechanism

IS

the

Pper

adVSTICe

motor

running

at the correct temperature (not

❑

Checked

❑

Not

n=essa~

Printer

overheating)

units

Is the

type

of paper in the printer

feeding

smoothl~

❑

Checked

❑

Not necessary

Is the tractor feeding the paper

❑

Checked

❑

Not necessary

Paper path

~rr-lw

Is the paper path

cfear

of all

❑

Chackedn Not necessary

obstructions?

Is the platen free of damage?

❑

Chackad

❑

Not necessary

Ribbon

IS

the

ritin

mask

free

of distortion?

❑

Checkedn

Not necessary

mask

Self-print

test

Was the

self~rint

successful?

❑

Checked D Not

neceasaty

On-line test

Was the on-line test

suocess

fui9

❑

Checked

❑

Not necessary

Is the platen gap adjusted correctly?

H

Checked

❑

Not necessary

Printhead

printing

IS

the bidirectional print position

Adjustmen

t

❑

Checkedn

Not necessary

adjusted

corractfy?

Defautt

Have user changeable settings been

❑

Checked

❑

Not necessary

setting

reset to the default value?

ROM

ROM version

❑

Checkecf

❑

Not necessary

version

System

Has the ribbon been removed?

❑

Checked

❑

Not necessary

upgrade

Shipment

Have all relevant parts been included

❑

Chalked

❑

Not

necessa~

in the shipment?

i,-.

r

:

,..

3-2

Rev.A

Loading...

Loading...