Troubleshooting

LX-300 Service Manual

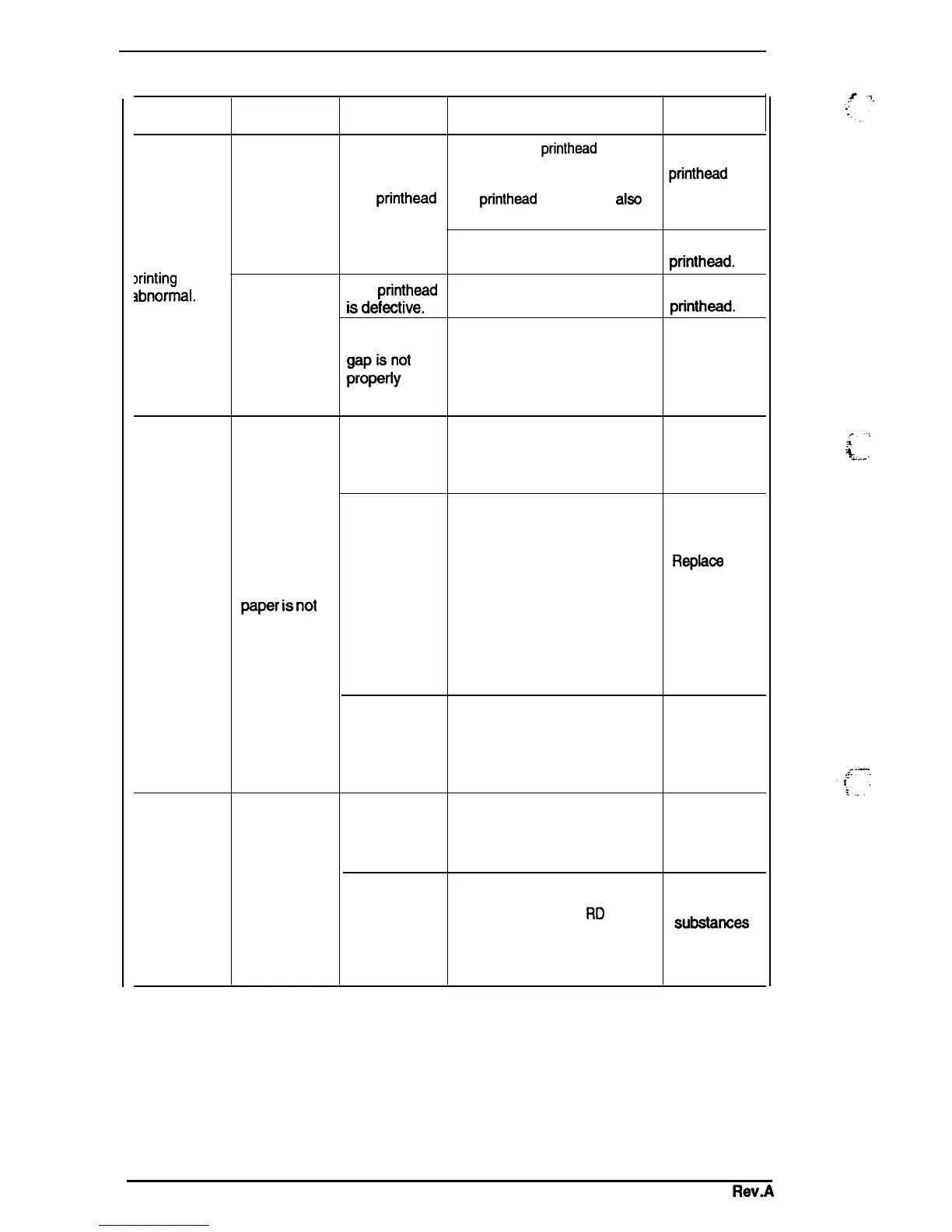

Table 5-9. Repairing the Printer Mechanism (Continued)

Problem

Symptom

Cause

Check Point

Solution

Measure the

printhead

coil

Replace the

resistance. It should be

approximately 33.3 ohms. If

printhead

(and

A particular

The

printhead

the

printhead

is

shorted,

ak)

drivers, if

dot is missing.

is defective.

check the drivers.

necessary).

Check to see if the dot wires

Replace the

Self-test

are worn.

printhead.

]rinting

is

~bnormal.

The

printhead

Check whether the tips of the

Replace the

The printing is

is

cfef=ti’Je”

wires are worn.

printhead.

too light, or

The platen

Set the gap adjustment lever to

Adjust the

the print

density is not

;:;:;ot

the first position, and check the

gap. Refer to

platen gap.

Section 4.1.1,

uniform.

adjusted.

The appropriate value is 0.45

Platen Gap

mm.

Adjustment.

Foreign

substances

Perform a visual cheek of the

Remove any

are lodged in

foreign

paper path.

the paper path

.

substances.

Remove any

foreign

substances.

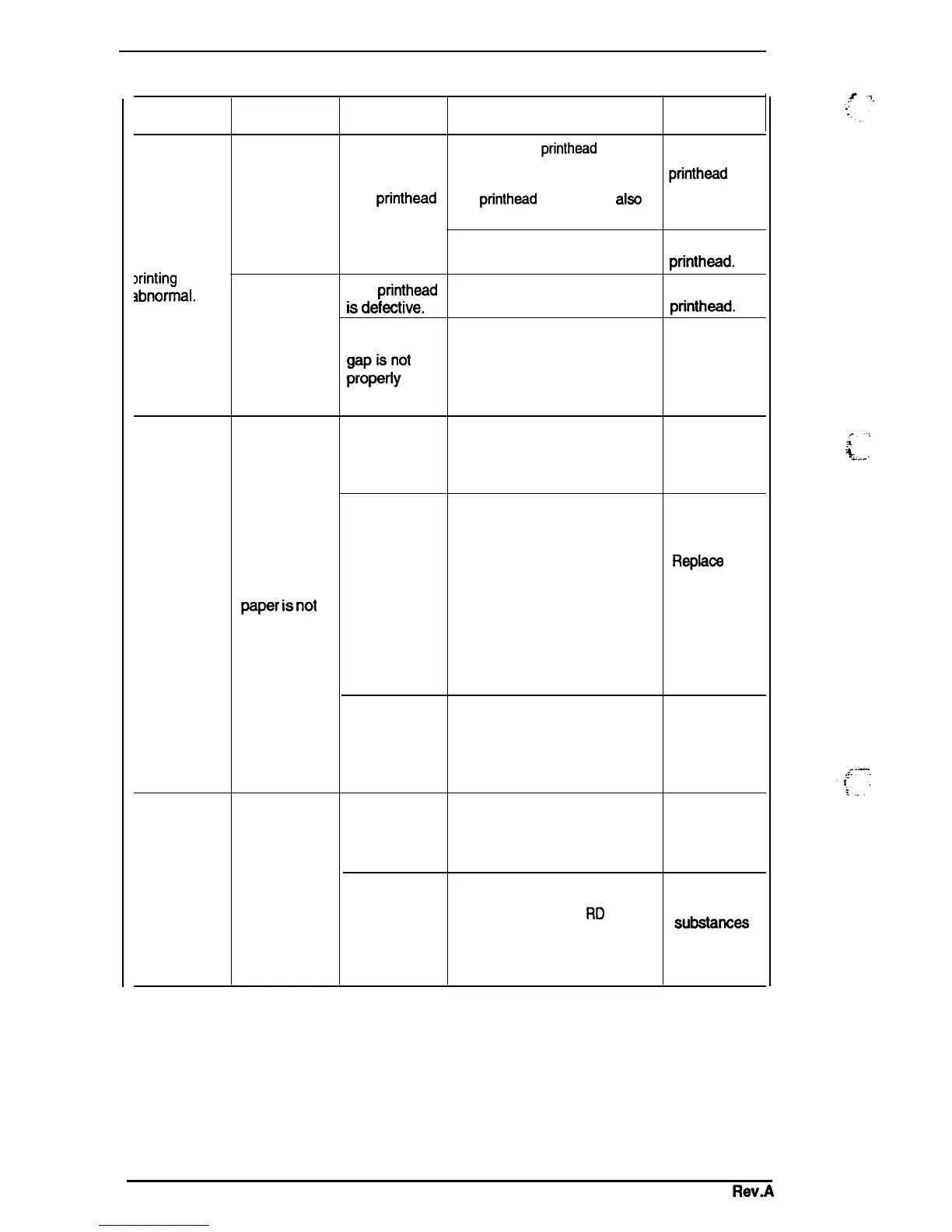

Printing is per

- The PF motor

Check that no foreign

Replaoe

the

formed but the assembly is

PF motor

Paper feed is

~per

is

not

substance is lodged between

not driving the

the gears and that the gears

assembly

abnormal.

fed or is not

gear correctly

. are not broken or worn.

reduction

fed uniformly.

gears.

Replace the

paper pickup

gears.

Measure the coil resistance fo

r Replace the

The PF motor

the PF motor assembly. The PF motor

assembly is approximate value should be

assembly

defective. 56 ohms. If the motor is

(and drivers, if

shorted, also check the drivers

. necessary).

The ribbon

Remove the ribbon cartridge,

rotate its knob manually, and

Replace the

cartridge is

see if the ribbon feeds

ribbon

defective.

normally.

cartridge.

The ribbon

feed is

The ribbon is

Remove any

abnormal.

not turning.

Foreign

foreign

Check whether the

RD

ratchet

Suktam=

substances

are caught in

rotates when the carriage is

moved manually.

Replace the

the gears.

ribbon feed

mechanism.

5-14

Rev.A

Loading...

Loading...