LX-

Servica Manual

Maintenance

6.1 PREVENTIVE MAINTENANCE

Preventive maintenance includes regular cleaning of the case exterior (using denatured alcohol), as

well as occasional vacuuming of the mechanism’s interior to remove dust and paper debris. After

cleaning the unit, check that it is adequately lubricated

(as described in Section

6.2, below). Before

returning the printer to the customer, inspect the springs, paper-feed rollers, and basic operation.

Disconnect the

printerfiom

the external AC power source before performing maintenance.

Do not use thinner,

trichloroethylene,

or ketone-based solvents

on

the plastic components

of the printer.

6.2 APPLYING LUBRICATION

EPSON

recommends that the

printer be lubricated at the points illustrated in Figure

61.

Table 6-2

lists each point along with its

recommen

ded lubricant. The recommended lubricants are EPSON

G-20, G26 and O-2, all of which have been tested extensively and found to comply with the needs

of this printer. (Table 6-1 provides details about these lubricants.) Before applying a lubricant, be

sure that the surface to be lubricated is clean. Do not apply too much lubricant, as this may

darnage nearby parts.

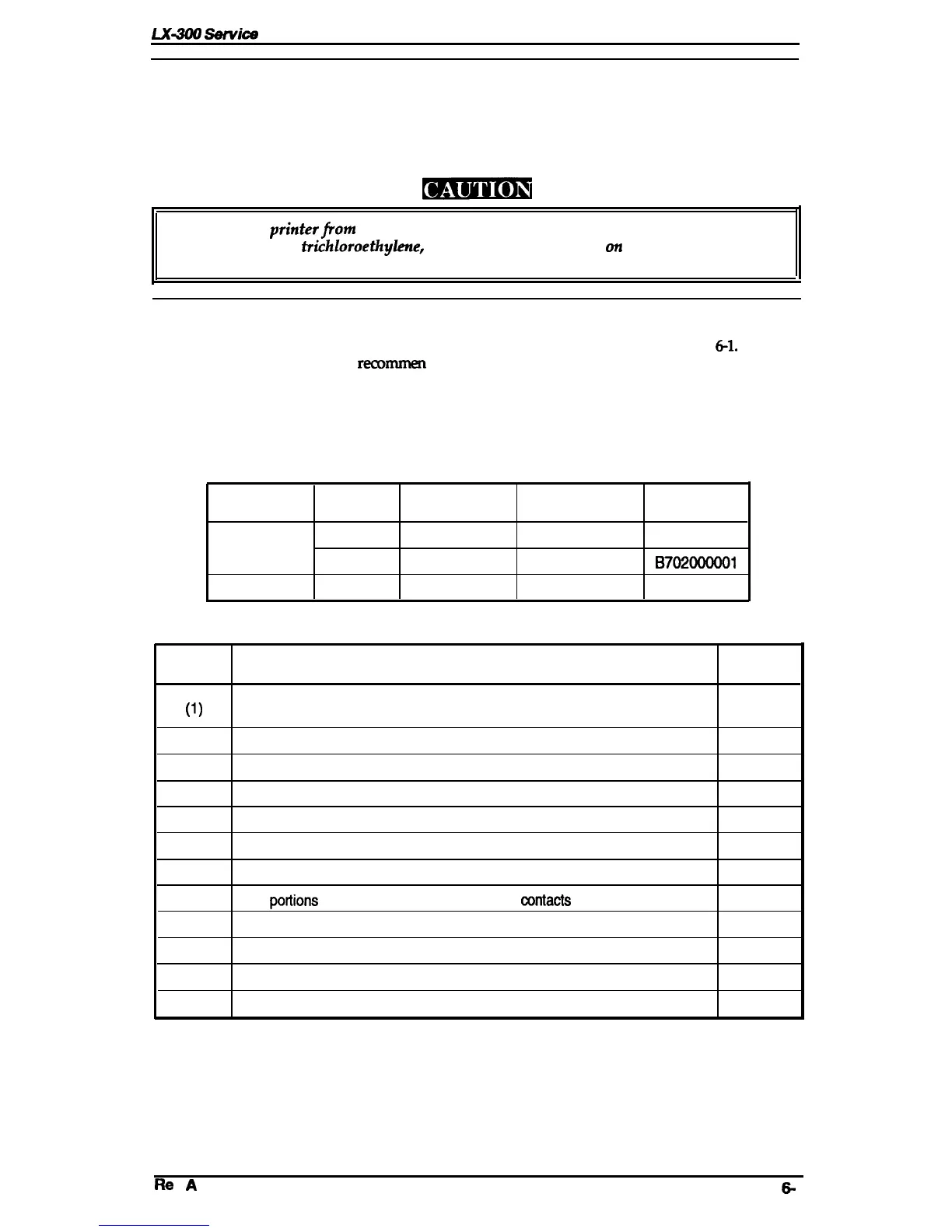

Table 6-1. Lubrication

Type

Name

Quantity

Availability

Part No.

G-26

40 gm EPSON

B702600001

Grease

G-20

40 gm

EPSON

B702ml

Oil

o-2

40CC

EPSON

B703700001

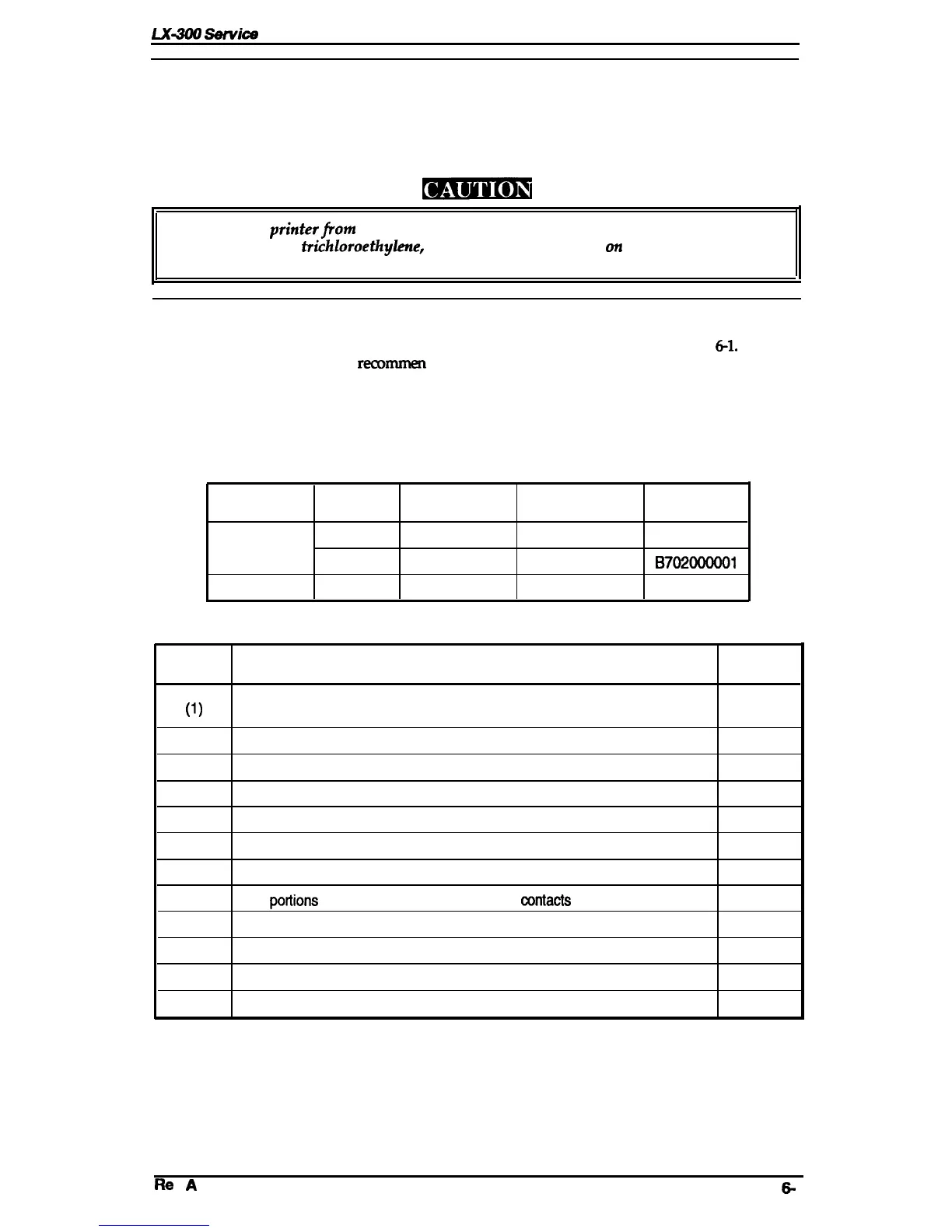

Table 6-2. Lubrication Points

Ref. No.

Lubrication Pointa

Lubricant

(1)

The hooks that attach the CR motor assembly to the base frame.

(3 places)

G-26

(2)

The shafts for the gear train on the left frame.

G-26

(3) The shafts for the gear train on the right frame.

G-26

(4)

The contact surface of the release lever and tractor transmission gear.

G-26

(5) The oil pad in the carriage assembly.

o-2

(6)

The teeth of gear 34.

G-26

(7)

The point at which the platen ground spring contacts the platen shaft.

G-20

(8)

The

pottions

of the carriage assembly that

oontacts

the CR guide frame.

G-26

(9)

The contact portion of the left tractor frame and tractor shaft.

G-26

(lo)

The contact point of the right tractor frame and tractor shaft.

G-26

(11) The contact point of the driven pulley shaft and drive pulley.

G-26

(12) The contact point of the driven pulley shaft and drive pulley.

G-26

Note:

Lubrication must be applied during the reassembly process.

Loading...

Loading...