EPSON Stylus COLOR 670 Revision A

Operating Principles Overview 36

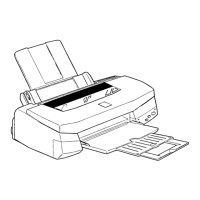

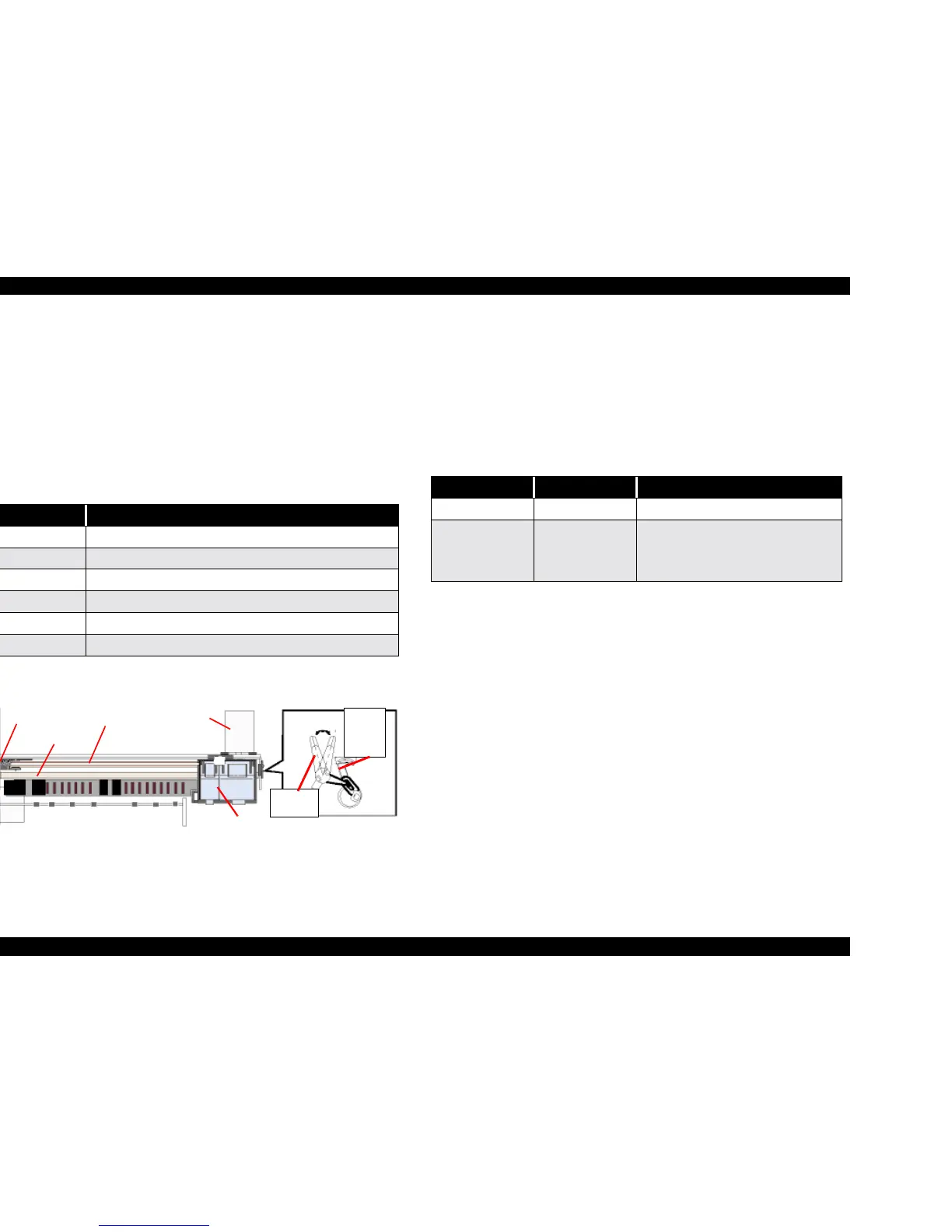

2.1.3 Carriage Mechanism

The carriage mechanism consists of carriage motor (CR motor), carriage unit

(including printhead), CR timing belt, CR guide shaft, CR guide frame, CR

home detector (HP sensor) etc.

The carriage mechanism moves the carriage back and forth according to the

drive from the carriage motor. (See Figure 2-4)

The following stepping motor is mounted to drive CR mechanism. (See the

table below.)

The drive from CR motor is transferred to the CR unit via CR timing belt.

Figure 2-4. Carriage Mechanism (Top view)

2.1.3.1 Platen Gap (PG) Adjustment Mechanism

The PG adjustment mechanism is designed to keep the platen gap correct for

the paper thickness to prevent ink from smearing.

The PG support lever joins the CR guide shaft, which has an eccentricity

toward PG support lever. Switching the lever from “0” to “+” rotates the CR

shaft and changes the platen gap from narrow to wide (within the range of

1.14mm to 2.04mm).

Table 2-2. Carriage Motor

Items Specifications

Type 4-Phase/ 200-Pole HB Stepping motor

Drive Voltage +42 V +/ - 5% (DRV IC voltage)

Coil Resistance 7.8 Ω +/ - 105 (per phase)

Inductance 14 mH +/ - 20%

Drive Method Bi-Polar drive

Driver IC LB11847

PF Roller

Timing Belt

CR motor

CR unit

Right

Parallel

Adjust

Bushing

PG Adjust

Lever

Driven Pulley

Table 2-3. Platen Gap Adjustment

Paper Lever Position PG adjustment value

All Media Front (0) 1.14mm between head and platen

If you find any

print problems or

you use thick

paper.

Rear (+) 2.04mm between head and platen

Loading...

Loading...