Corrective Maintenance

Fox Maintenance © Essemtec AG 5-7

0000074/05

/ March 31,

2017

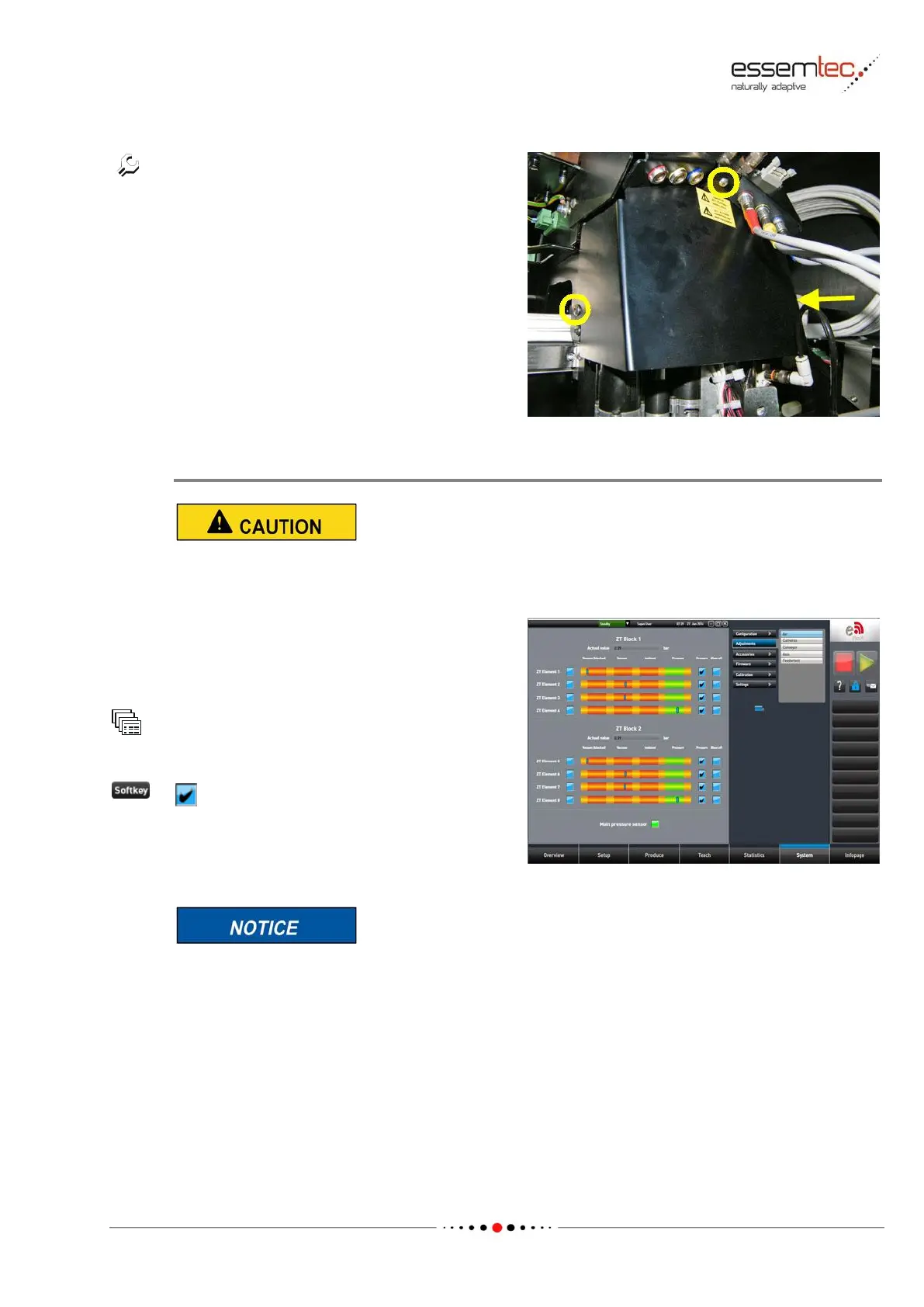

On top of the head, loosen and remove the 3

fixing screws of the top cover (see picture).

Carefully remove the cover.

The rinsing liquid can splash into your eyes, serious injury could occur. Wearing safety

goggles will reduce this hazard.

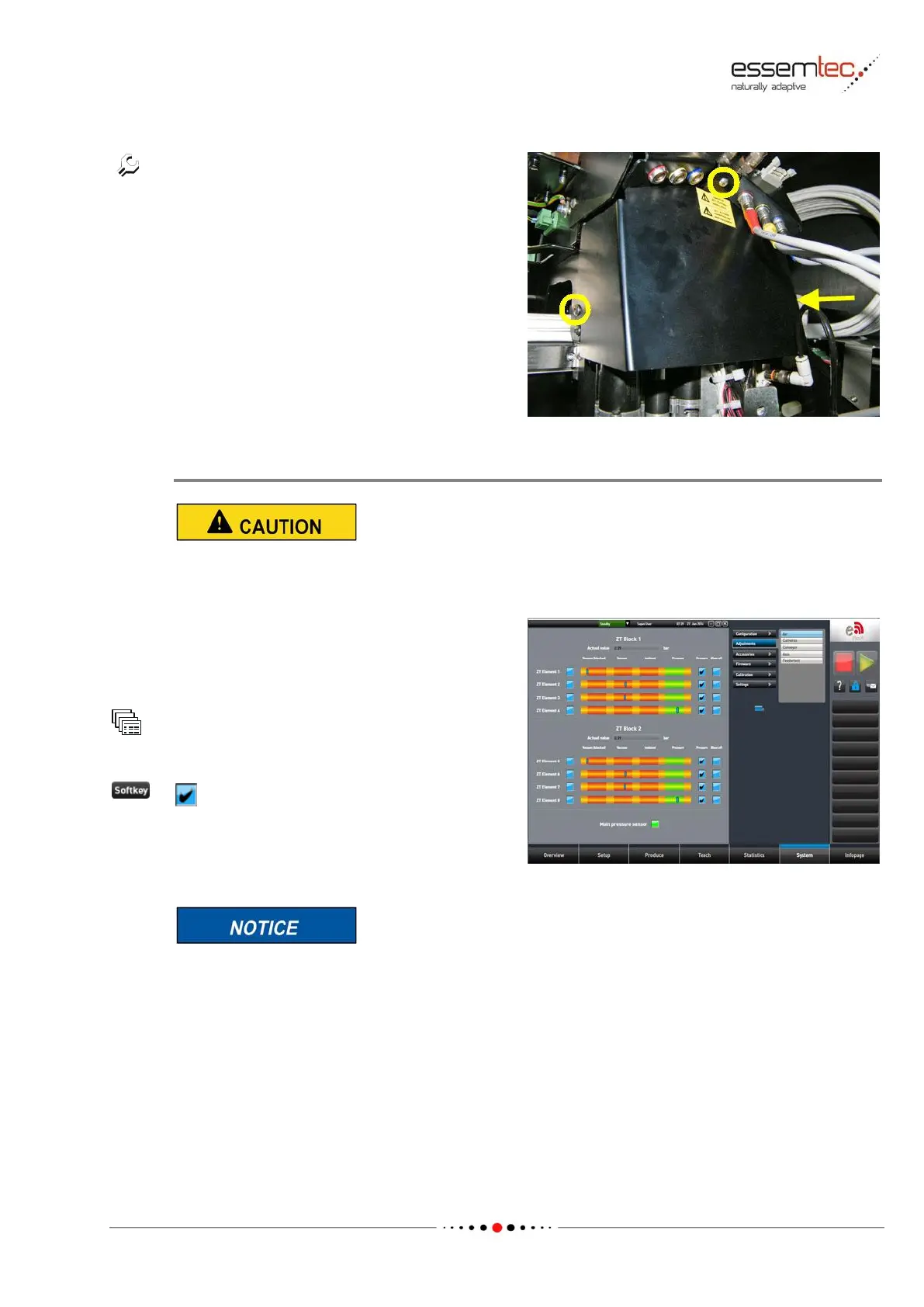

Switch on the air blow on each ZT element

which exists on the machine (because the

software is developed for various machine types,

8 ZT elements are visible).

System

Adjustments

Air

on all ZT elements on the Pressure side to

switch on the air blow (all elements must blow).

The air blow ensures that no liquid and no dirt is

sucked into the vacuum valve and the system.

If a blow off valve is installed (option), it is mandatory to follow the next single step called

Blow off. To protect the blow off valves and to avoid the contact of the valves with rinsing

fluid, it is important to remove the vacuum hose at the correct position.

Without blow off valve, follow the next single step called No blow off.

Do the following steps for all ZT elements (if more than one exists). But to avoid any risk of

hose confusion, do just one ZT element after the other.

Loading...

Loading...