4. Maintenance

USE AND MAINTENANCE MANUAL CHAPTER 4

MAINTENANCE2-Strokes - Edition 00 / 2023

121

4

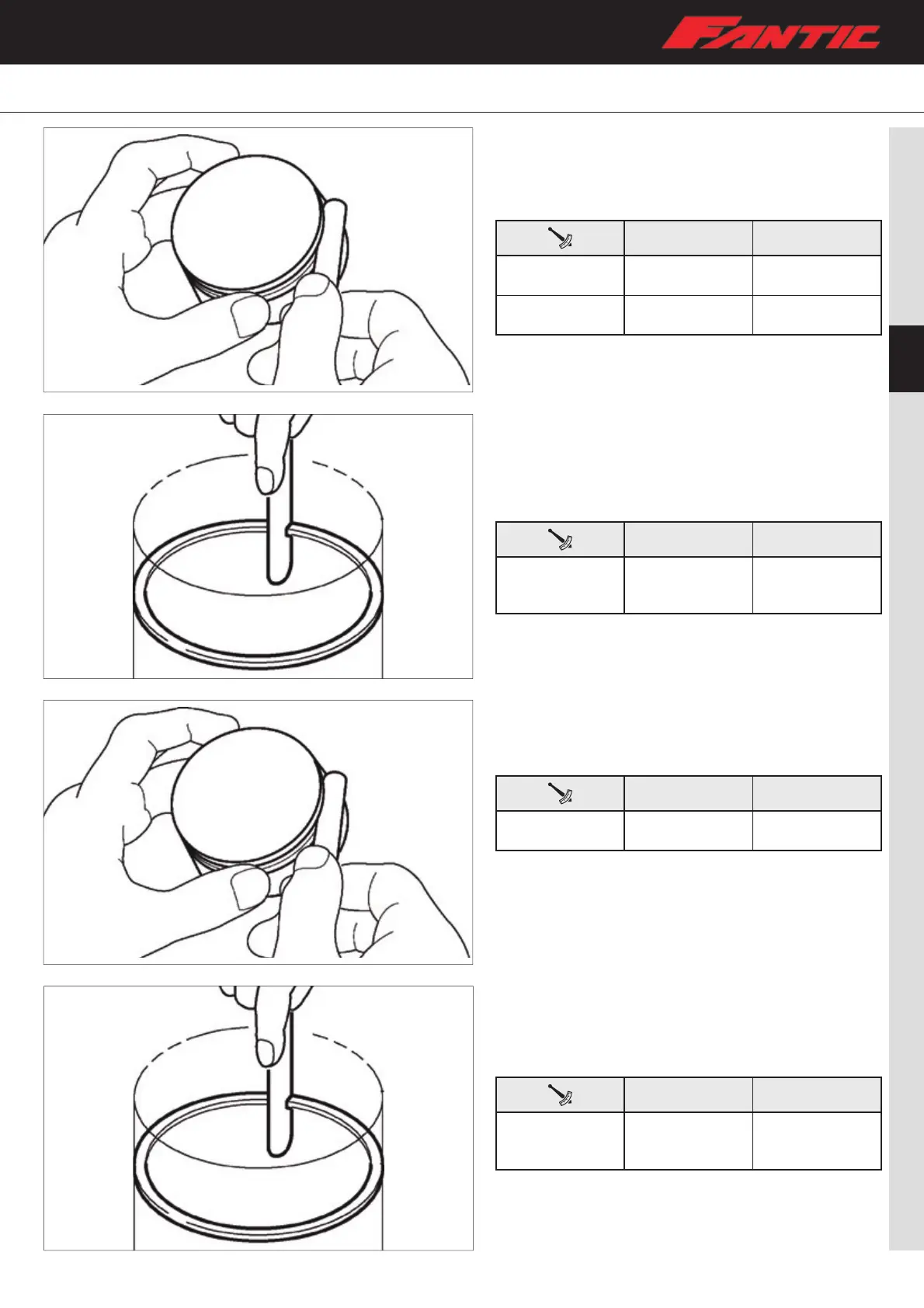

Segments check (XX 250 version)

– Remove carbon deposits from the segments and their

grooves.

– Using a thickness gauge, measure the lateral clearance of

the segments.

Standard Limit

First segment

lateral clearance

0.030–0.065 mm

(0.0012–0.0026 in)

0.100 mm

(0.0039 in)

Second segment

lateral clearance

0.030–0.065 mm

(0.0012–0.0026 in)

0.100 mm

(0.0039 in)

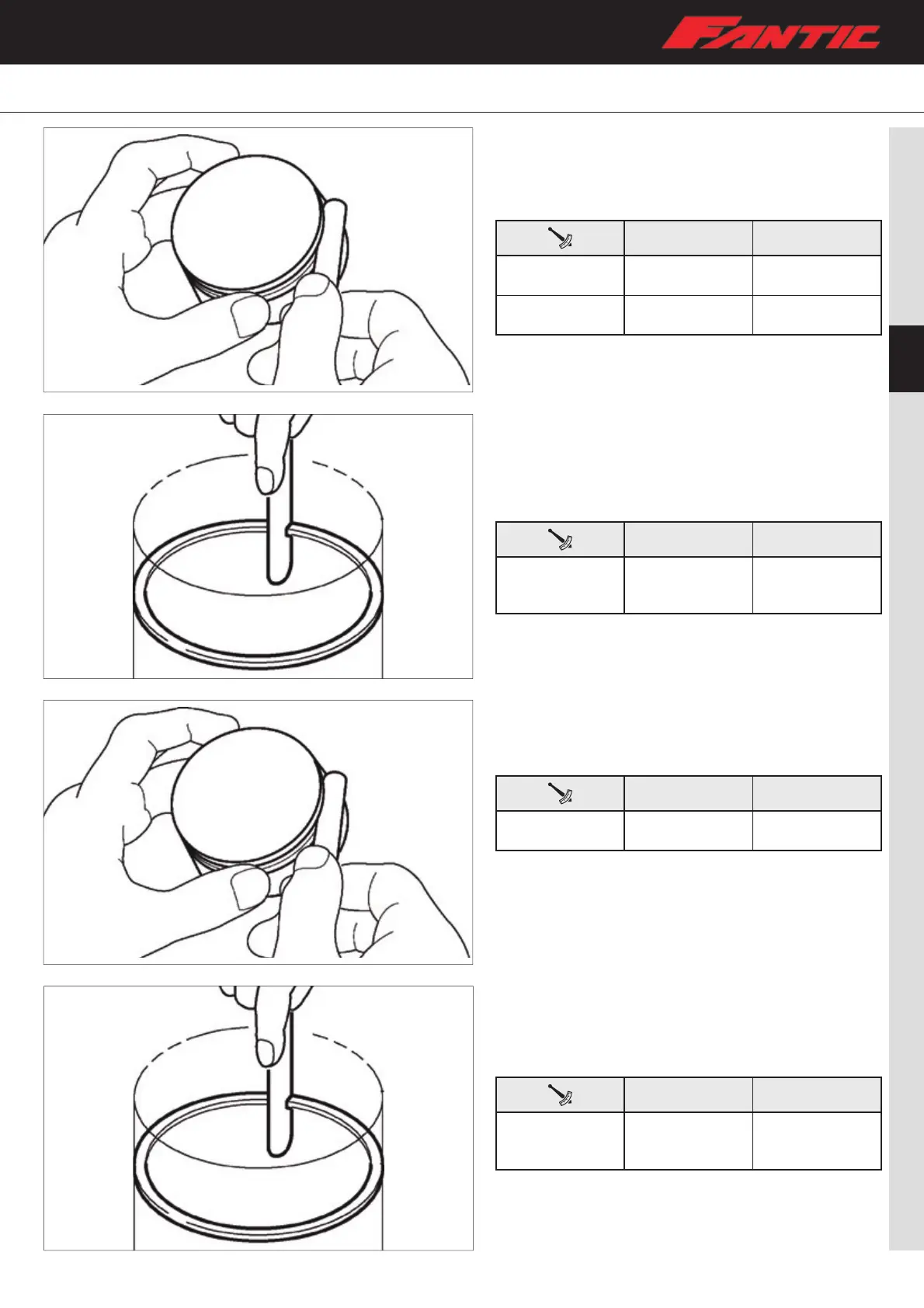

– Insert one segment at a time into the cylinder, using the

crown of the piston to position and level the segment at

the bottom of the cylinder (zone where wear is minimal).

– Measure the clearance between the ends of the segments,

if it is not in accordance with the specifications replace the

segments all together.

Standard Limit

Distance between

ends of piston rings

(installed)

0.700 mm

(0.0276 in)

Segments check (XX 125 / XE 125 versions)

– Remove carbon deposits from the segment and its groove.

– Using a thickness gauge, measure the lateral clearance of

the segment.

Standard Limit

Lateral segment

clearance

0.035–0.070 mm

(0.0014–0.0028 in)

0.100 mm

(0.0039 in)

– Insert the segment into the cylinder, using the crown of the

piston to position and level the segment at the bottom of

the cylinder (zone where wear is minimal).

– Measure the clearance between the ends of the segment,

replace if not in accordance with specifications.

Standard Limit

Distance between

ends of piston ring

(installed)

1.20 mm

(0.0472 in)

Loading...

Loading...