Operation

Before You Measure

4

4-27

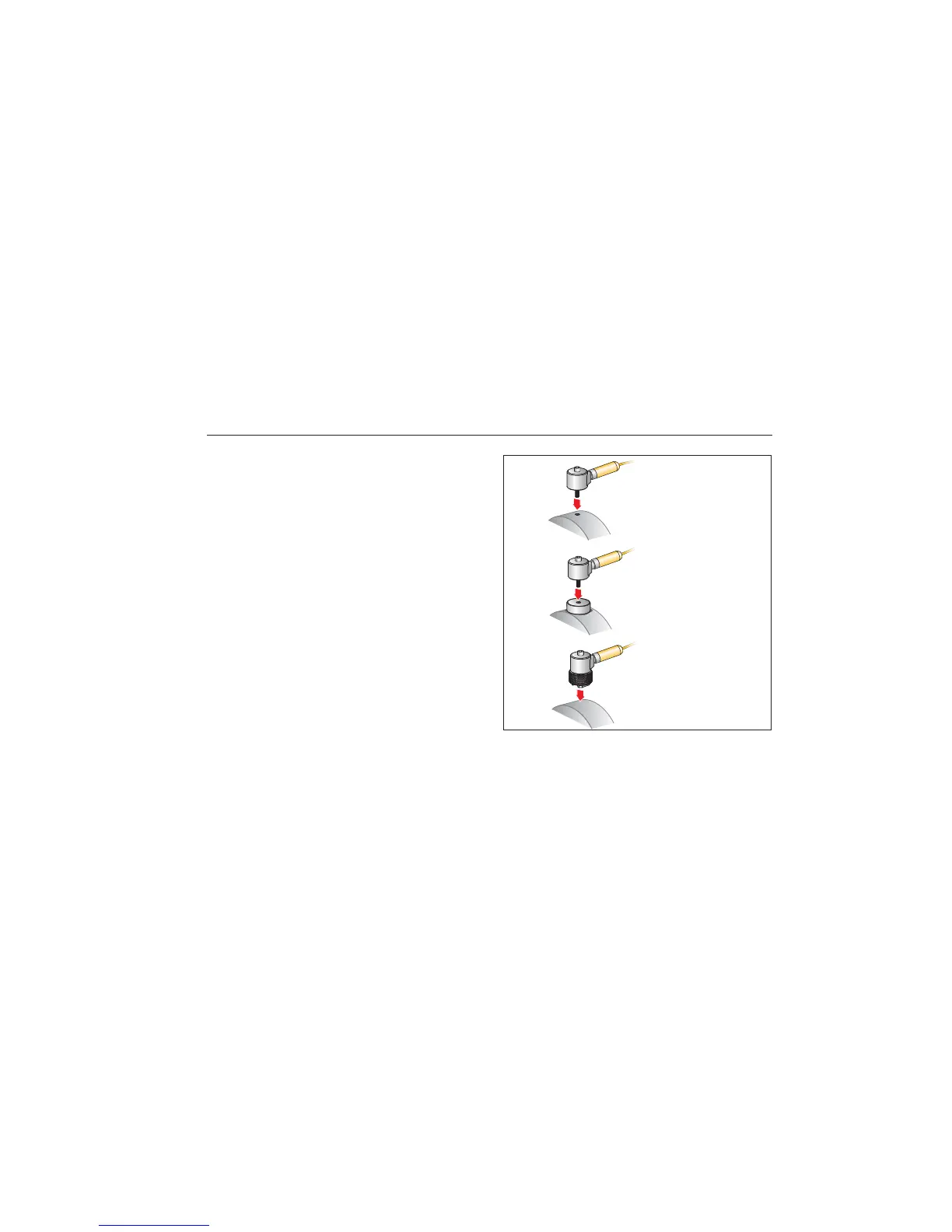

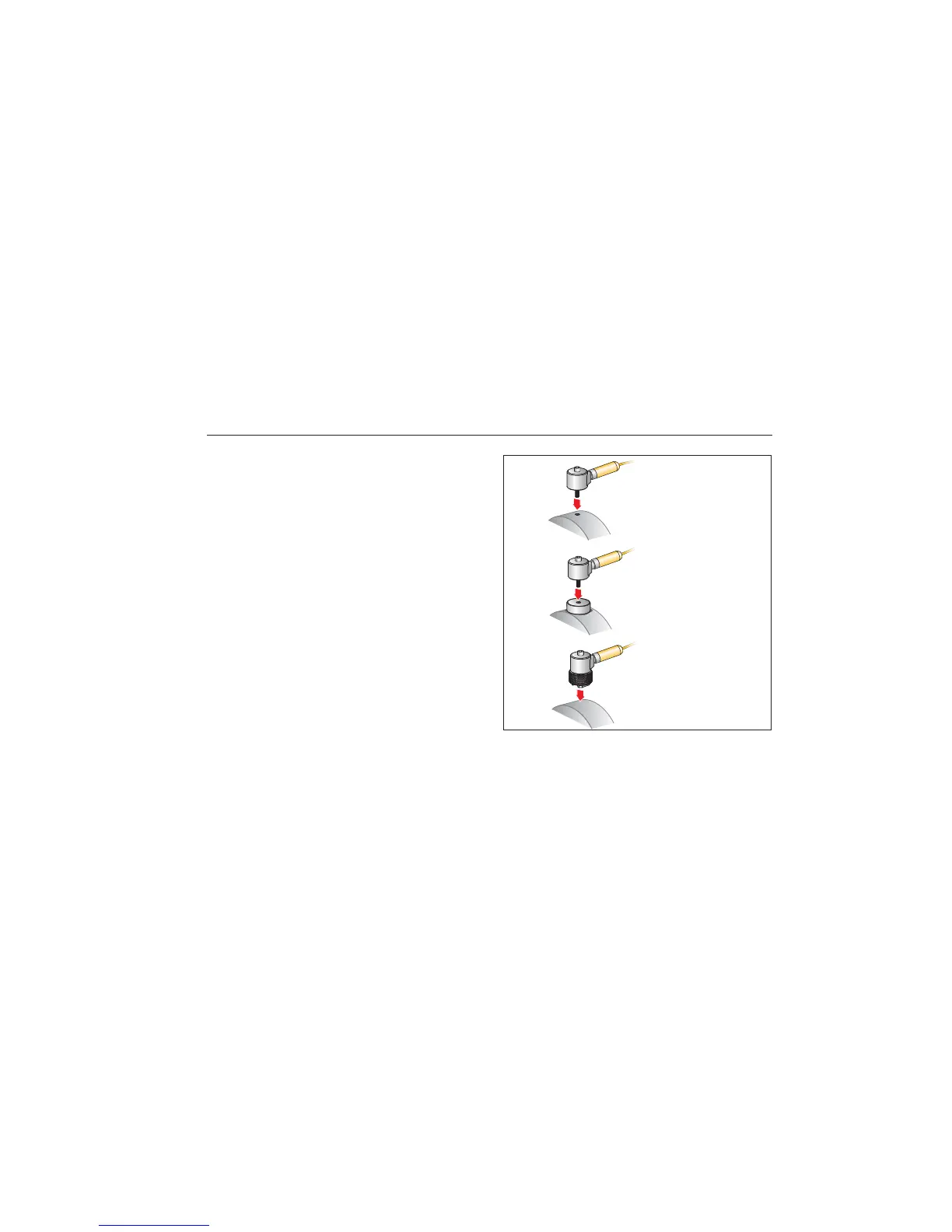

Sensor Mounting

The Tester’s diagnoses are largely dependent upon the

quality of vibration signal it receives from the machinery

under test. The method used to mount a Sensor to the

machine directly affects the quality, accuracy, and range

of the signal, see Figure 4-3.

In general, permanent mounts, such as stud or adhesive

mount, yield the best results. These are best for

machines that:

• run at high speeds and frequencies

• have a driving unit that runs at greater than

6000 RPM (for example, vacuum pumps)

• include a speed changer (gearbox) that results in an

output shaft speed of greater than 5x the input shaft

speed

• include an integrated speed changer (for example,

centrifugal compressors)

Permanent mountings promote more consistent data if

tracking machine condition over time. The advantages

and disadvantages of permanent mounts are as follows.

Stud Mount

Adhesive Mount

Magnetic Mount

gbk11.eps

Figure 4-3. Sensor Mounting Options

Stud Mounting

Stud mounting is typical for permanently mounted

applications. A hole is tapped into a flat section of the

Loading...

Loading...