102

Macros

96-8000 rev R June 2007

Example 2: G00 G90 X1.0 Y1.0 Z.05 S1000 M03; (Position tool)

G65 P9010 X.5 Y.25 Z.05 F10. T10; (Call 9010)

G28;

M30;

O9010; (Diagonal hole pattern)

F#9; (F=Feed rate)

WHILE [#20 GT 0] DO1; (Repeat T times)

G91 G81 Z#26; (Drill To Z depth)

#20=#20-1; (Decrement counter)

IF [#20 EQ 0] GOTO5; (All holes drilled)

G00 X#24 Y#25; (Move along slope)

N5 END1;

M99; (Return to caller)

Aliasing

Aliasing is a means of assigning a G-code or M-code to a G65 P##### sequence. For instance, in Example 2 it

would be easier to write:

G06 X.5 Y.25 Z.05 F10. T10;

When aliasing, if you alias to a G-code you may pass variables with it. If you alias to an M-code, you may NOT pass

variables with it.

Here, an unused G code has been substituted, G06 for G65 P9010. In order for the previous block to work the

parameter associated with subroutine 9010 must be set to 06 (Parameter 91). Note that G00, G65, G66, and G67

cannot be aliased. All other codes between 1 and 255 can be used for aliasing.

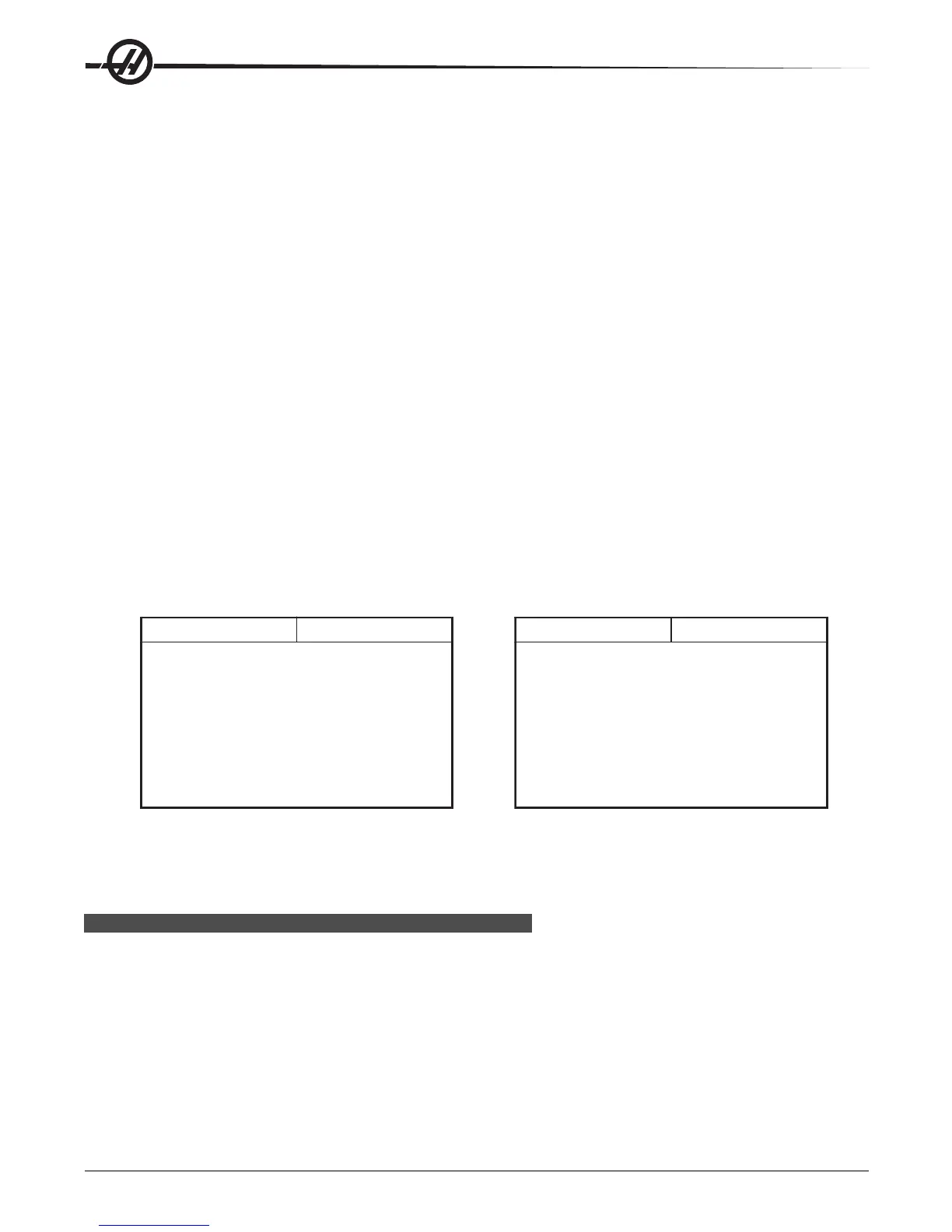

Program numbers 9010 through 9019 are reserved for G code aliasing. The following table lists which HAAS param-

eters are reserved for macro subroutine aliasing.

retemaraPsaaHedoCO

19

29

39

49

59

69

79

89

99

001

0109

1109

2109

3109

4109

5109

6109

7109

8109

9109

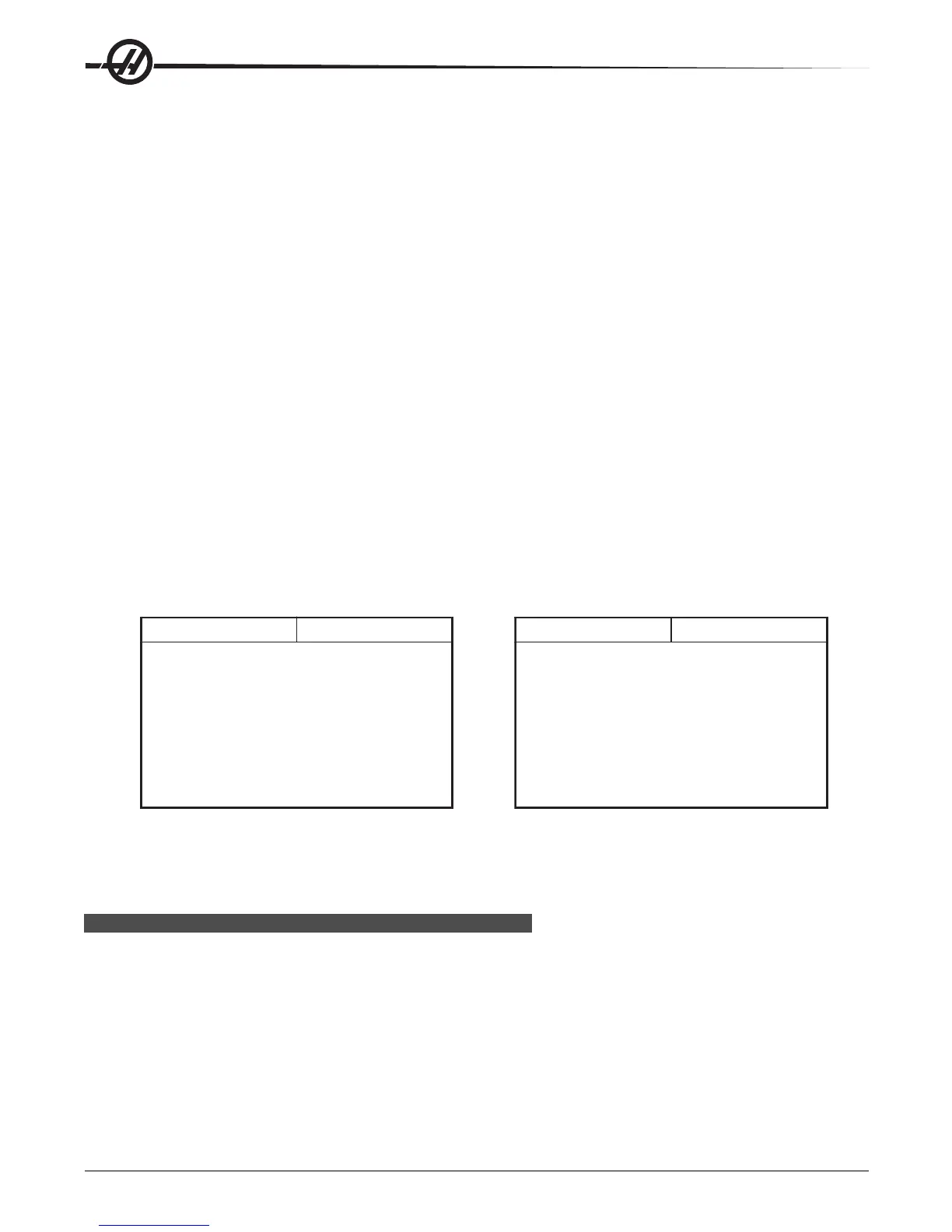

retemaraPsaaHllaCorcaMM

18

28

38

48

58

68

78

88

98

09

0009

1009

2009

3009

4009

5009

6009

7009

8009

9009

G-Code Aliasing M-Code Aliasing

Setting an aliasing parameter to 0 disables aliasing for the associated subroutine. If an aliasing parameter is set to a

G-code and the associated subroutine is not in memory, then an alarm will be given.

COMMUNICATION WITH EXTERNAL DEVICES - DPRNT[ ]

Macros allow additional capabilities to communicate with peripheral devices. One can do digitizing of parts, provide

runtime inspection reports, or synchronize controls with user provided devices. The commands provided for this are

POPEN, DPRNT[ ] and PCLOS.

Communication preparatory commands

POPEN and PCLOS are not required on the Haas mill. It has been included so that programs from different controls

can be sent to the Haas control.

Loading...

Loading...