Operation

56

96-8000 rev R June 2007

PALLET C HANGER (EC-SERIES AND MDC-500)

Introduction

The pallet changer is commanded through a program in CNC memory. The M50 (execute pallet change) function

consists of unlocking, lifting and rotating the pallets, then lowering and locking the pallets again. The pallet changer

rotates the pallets 180

o

, then back; it does not continuously rotate in the same direction.

The pallet changer is provided with an audible signaling device to alert nearby personnel when a pallet change is

taking place. However, do not depend on the signal to avoid mishaps.

Pallet Changer Warnings and Cautions

• Large workpieces may collide into frame during a pallet change.

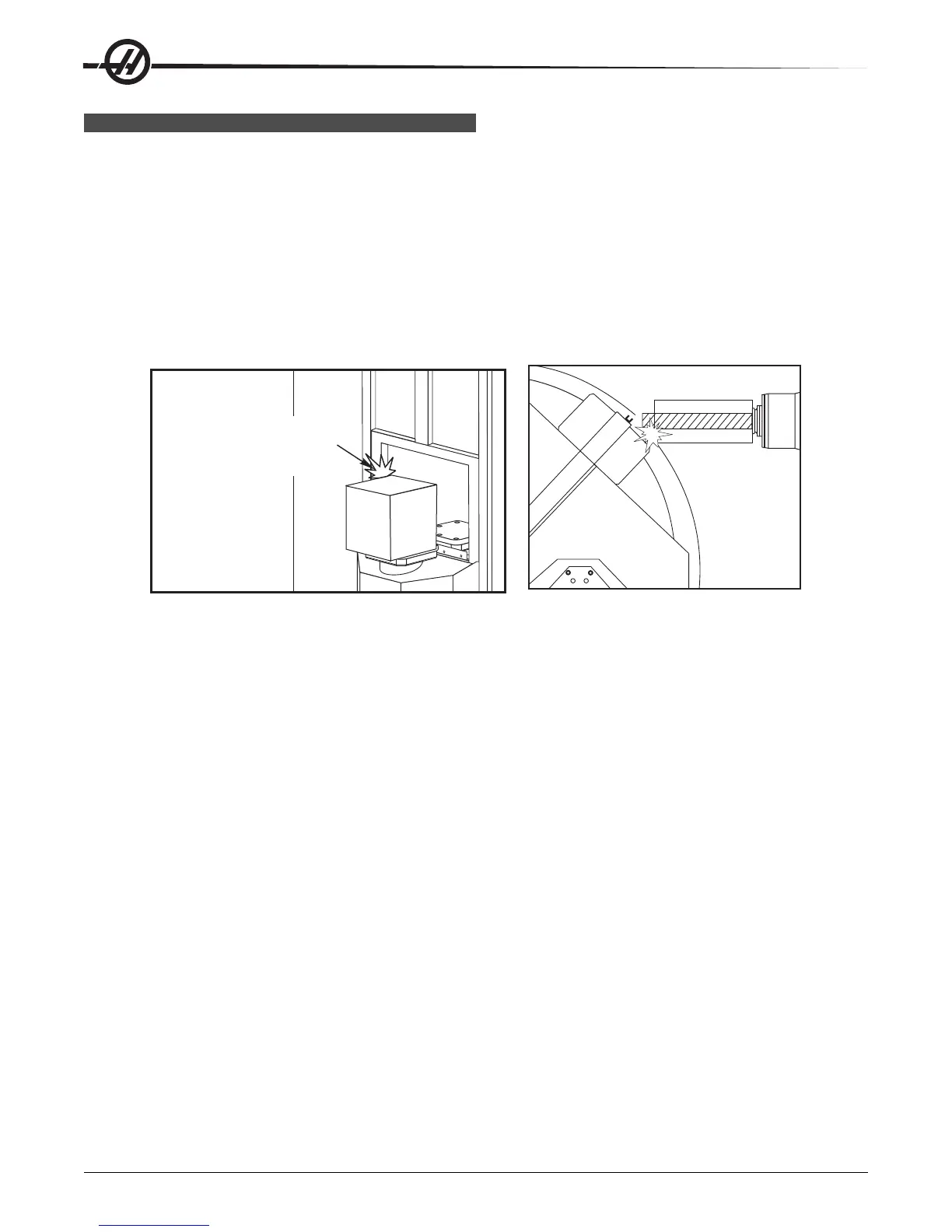

• Verify tool length clearance during pallet changes. Long tools may collide with workpiece.

Plane3

Items Beyond the Maximum

Radius and Height Limits

Will Damage the Machine

When the Pallet Rotates

EC-300 Shown

Maximum Pallet Loads

EC-300 550lb (249kg) per station, balanced within 20%

MDC 700lb (318kg) per station, balanced within 20%

EC-400 1 and 45 degree indexer – 1000 lb per pallet

Full 4th Axis – 660 lb per pallet

Pallet Changer Operation

The Pallet Changer is commanded using M Codes.

M50 determines if a pallet has been scheduled. The pallets will change if a pallet is scheduled or the program will

pause and prompt the operator the pallet is not scheduled.

G188 uses the pallet schedule table to load and run the program scheduled for the current pallet. Once the part

program completes, the M99 command loops back to the M50 (pallet change) in order to load the next pallet.

M36 is not used in this method, as M50 monitors the pallet scheduling. M36 is provided for backward compatibility,

and to program pallet changes without using PST.

Messages aid the operator with loading/unloading and pallet changes. For example, at the beginning of the M50

pallet change, if the load station is not ready, a message is displayed on the screen. The message will not stop

flashing and the pallet change will not continue until the load station is ready and the Part Ready button is pressed.

At the beginning of a pallet change, if the load station is ready, no messages appears, and no button press is

required, and the pallet change starts directly.

M46 – Qn Pmm

Jump to line mm in the current program if pallet n is loaded, otherwise go to the next block.

Loading...

Loading...