28

Introduction

96-8000 rev R June 2007

If the shuttle jog knob is turned from its centered position when the RJH-E is removed from its cradle, or

when the control mode is changed to a mode with motion (for instance, from MDI to Handle Jog mode), the

message "Shuttle off center—No Axis selected" appears on the RJH-E display and no axis motion will

occur. Move the axis selection knob to clear the error.

If the pulse jog knob is rotated while the shuttle jog knob is in use, the message "Conflicting jog

commands— Reselect Axis" appears on the RJH-E display, and all axis motion stops. Move the axis

selection knob to a different axis to clear the error.

Note: If any of the above errors fail to clear when the axis selection knob is moved, there may be a problem

with the shuttle jog knob. Contact Haas service for repair/replacement.

If contact between the RJH-E and the control is broken for any reason (cable cut or disconnected, etc.), all

axis motion stops. When reconnected, the message "RJH / Control Communication Fault—Reselect Axis"

appears on the RJH-E display. Move the axis selection knob to clear the error. If the error does not clear, place

the RJH-E in its cradle, wait for it to power off, and then remove from the cradle.

Note: This error can also indicate a fault in the SKBIF, the RJH-E, or the wiring. If the error persists, further

diagnosis and repair may be necessary.

RJH-E SRJH-E S

RJH-E SRJH-E S

RJH-E S

CREENSCREENS

CREENSCREENS

CREENS

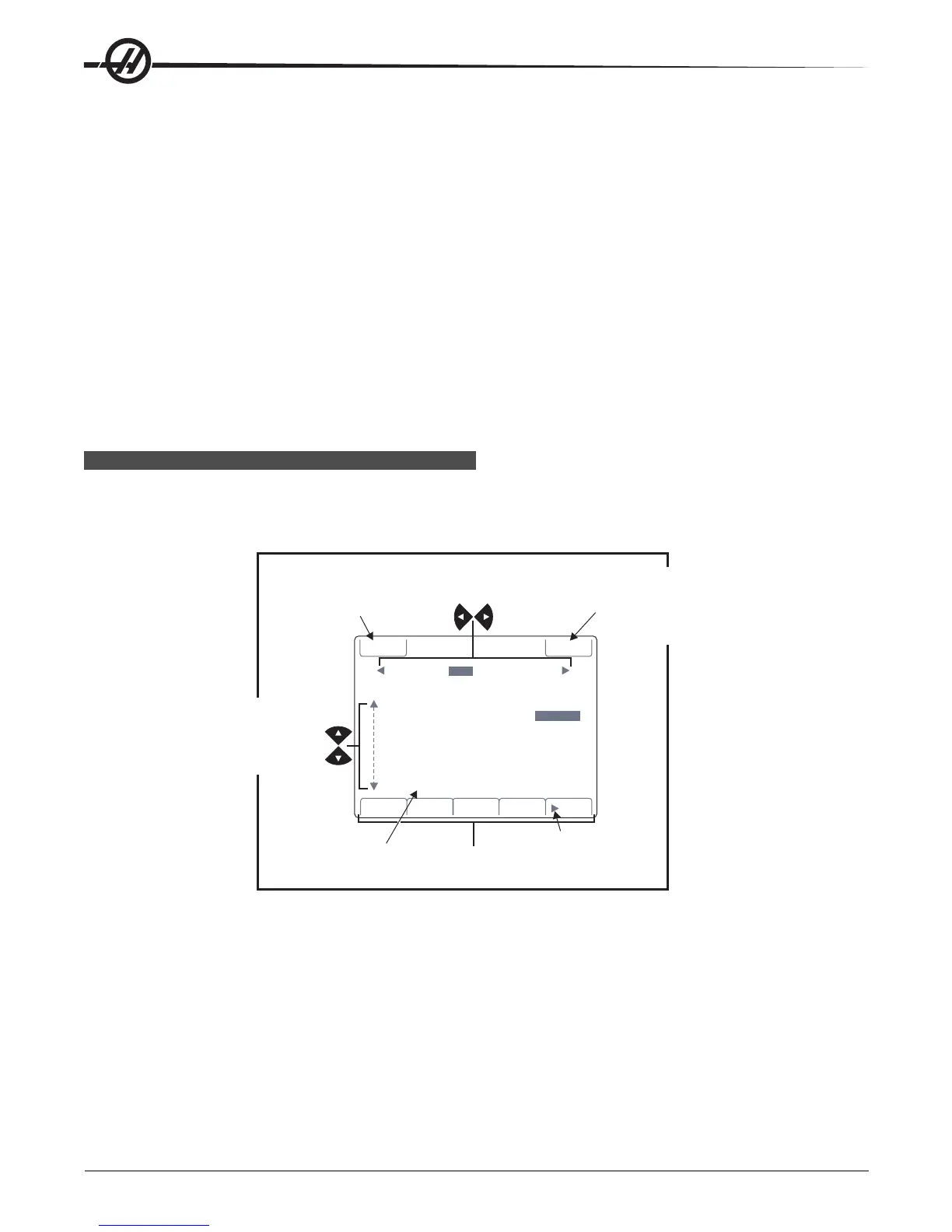

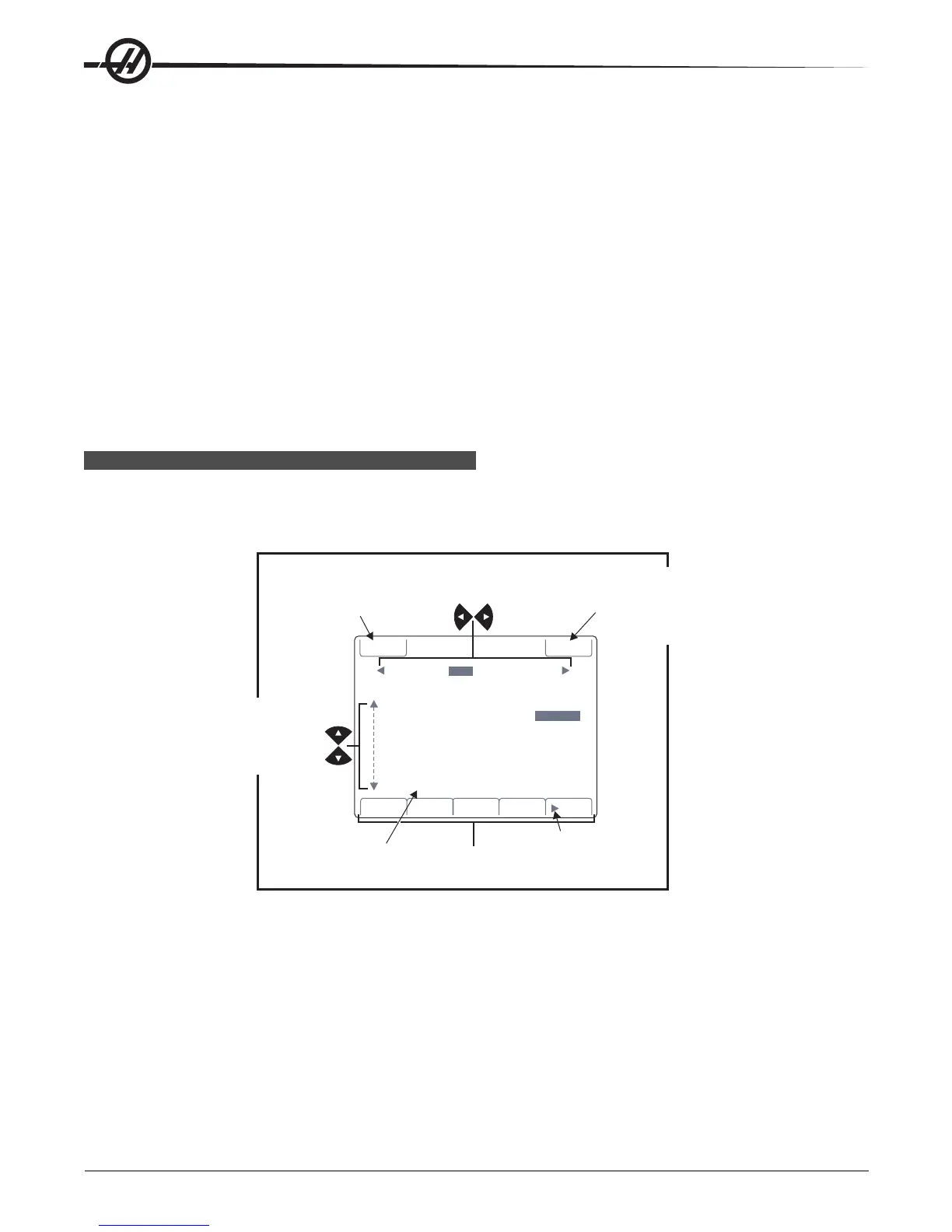

The RJH-E uses four different program screens to control manual jogging, set tool length offsets, set work

coordinates, and display the current program. The four screens display information differently, but navigating

and changing options are always controlled in the same way, as noted in this illustration.

JOGOFSET

Tool in spindle = 1

Tool offset (Hxx) =

1

Length offset = -2.0990

Length wear = 0.0010

Tool Diameter = 1.5000

Diameter wear = 1.5000

Coolant position = 0

Z 2.8346

SET Z NEXT PRIOR M06

WORK

Set Tool Offsets

.0001 - - .01 - .1.001

Function Keys

Current Display

Left/Right cursor to change pulse

jog rate (current highlighted)

Thumb knob

changes axis (must be

highlighted to jog)

Advance to next screen

Current control mode

on pendant

(JOG allows jogging,

MEM/MDI runs current

program)

Up/down arrows

to select fields

Change value with

Pulse Knob

Manual Jogging – This screen contains a large display of the current machine position. The currently se-

lected axis is highlighted and will move if the shuttle jog or pulse jog knobs are moved. Select another axis by

using the thumb knob. The jog rate for the pulse knob is displayed on the second line and can be adjusted with

the left and right arrow keys. Press ZERO to origin the operator coordinates only. Select WORK, MACH, or TO

GO to change the coordinate system (current highlighted). The fifth tab advances to the Tool Offset screen.

Loading...

Loading...