133

G Codes

96-8000 rev R June 2007

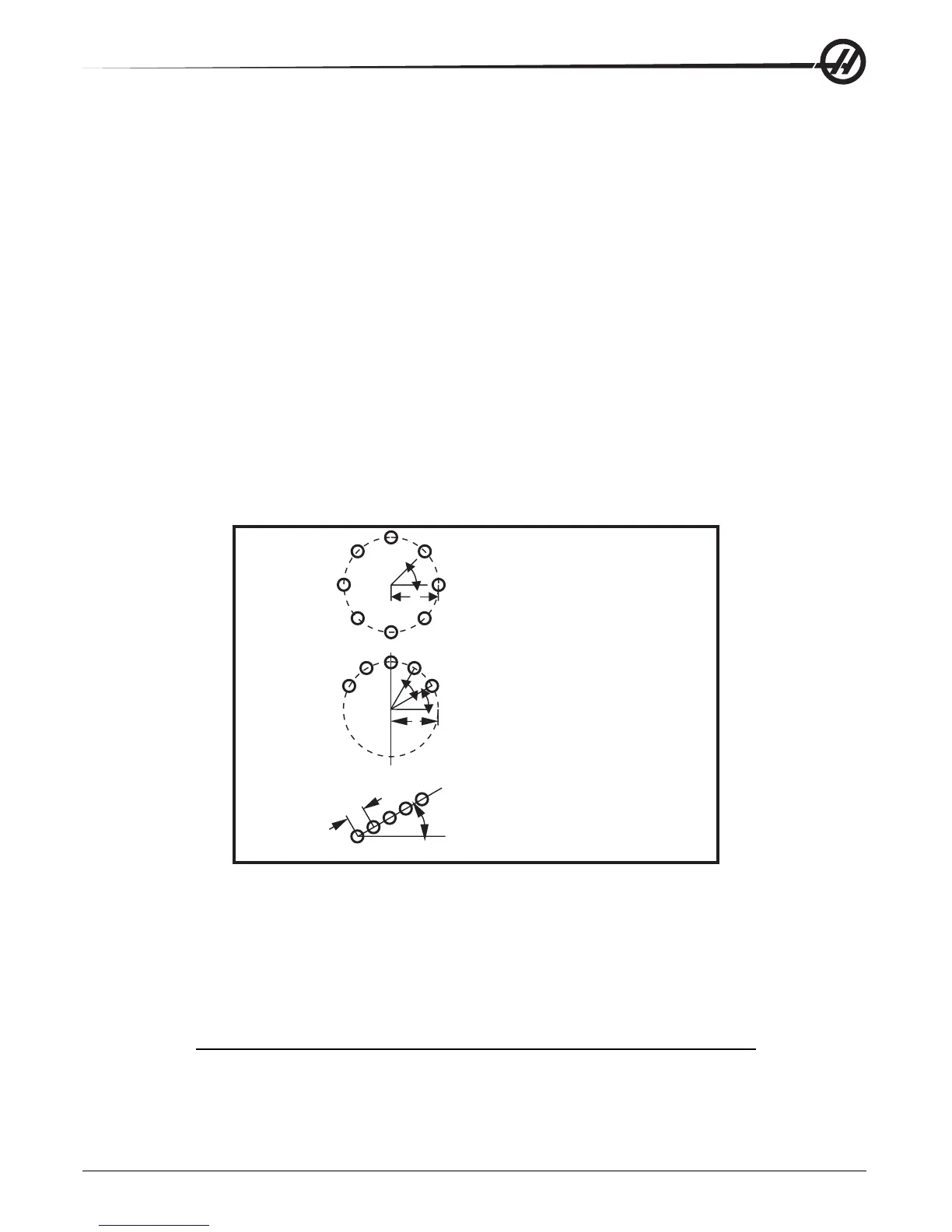

G70 Bolt Hole Circle (Group 00)

I Radius (+CCW / -CW)

J Starting angle (0 to 360.0 degrees CCW from horizontal; or 3 o’clock position)

L Number of holes evenly spaced around the circle

This non-modal G code must be used with one of the canned cycles G73, G74, G76, G77, or G81-G89. A canned

cycle must be active so that at each position, a drill or tap function is performed.

G71 Bolt Hole Arc (Group 00)

I Radius (+CCW / -CW)

J Starting angle (degrees CCW from horizontal)

K Angular spacing of holes (+ or –)

L Number of holes

This non-modal G code is similar to G70 except that it is not limited to a complete circle. G71 belongs to Group 00

and thus is non-modal. A canned cycle must be active so that at each position, a drill or tap function is performed.

G72 Bolt Holes Along an Angle (Group 00)

I Distance between holes (+CCW / -CW)

J Angle of line (degrees CCW from horizontal)

L Number of holes

This non-modal G code drills “L” number of holes in a straight line at the specified angle. It operates similarly to

G70. For a G72 to work correctly, a canned cycle must be active so that at each position, a drill or tap function is

performed.

I = Radius of the bolt circle

J = Starting angle from the 3 o'clock

position

L = Number of holes (evenly spaced)

I = Radius of the bolt circle

J = Starting angle from the 3 o'clock

position

L=Number of holes (evenly spaced)

I

J

I

I

J

J

K

I = Radius of the bolt circle

J = Starting angle from the 3 o'clock

position

K = Angular spacing between holes

L = Number of holes (evenly spaced)

I = Radius of the bolt circle

J = Starting angle from the 3 o'clock

position

K

= Angular spacing between holes

L=

Number of holes (evenly spaced)

I = Distance between holes

J = Starting angle from the 3 o'clock

position

L = Number of holes

I = Distance between holes

J = Starting angle from the 3 o'clock

position

L=Number of holes

G70

Bolt hole circle

G71

Bolt hole circle

G72

Bolt holes

along an angle

Rules For Bolt Pattern Canned Cycles:

1. The tool must be placed at the center of the bolt pattern before the canned cycle execution. The center is

usually X0, Y0.

2. The J code is the angular starting position and is always 0 to 360 degrees counterclockwise from the three

o’clock position.

Looping Canned Cycles

The following is an example of a program using a drilling canned cycle that is incrementally looped.

NOTE: The sequence of drilling used here is designed to save time and to follow the

shortest path from hole to hole.

Loading...

Loading...